Chapter 9 9-5

Accessories Troubleshooting

Inspect the Error Terms

Inspect the Error Terms

Error terms are a measure of a “system”: a network analyzer, calibration kit, and any

cables used. As required, refer to Chapter 11 , “Error Terms,” for the following:

• The specific measurement calibration procedure used to generate the error terms.

• The routines required to extract error terms from the instrument.

• Typical error term data.

Use Table 9-1 to cross-reference error term data to system faults.

If you detect problems using error term analysis, use the following approach to isolate the

fault:

1. Check the cable by examining the load match and transmission tracking terms. If those

terms are incorrect, go to “Cable Test” on page 9-6.

2. Verify the calibration kit devices:

• Loads (for 8753ES): If the directivity error term looks good, the load and the test port

are good. If directivity looks bad, connect the same load on the other test port and

measure its directivity. If the second port looks bad, as if the problem had shifted

with the load, replace the load. If the second port looks good, as if the load had not

been the problem, troubleshoot the first port.

• Loads (for 8753ET): If the directivity error term looks good, the load and the test port

are good. If directivity looks bad, connect a known good load to the Reflection port

and measure its directivity. If the directivity now looks good, replace the original

load. If the directivity still looks bad, troubleshoot the Reflection port.

• Shorts and opens: If the source match and reflection tracking terms look good, the

shorts and the opens are good. If these terms look bad while the rest of the terms

look good, proceed to “Verify Shorts and Opens” on page 9-6.

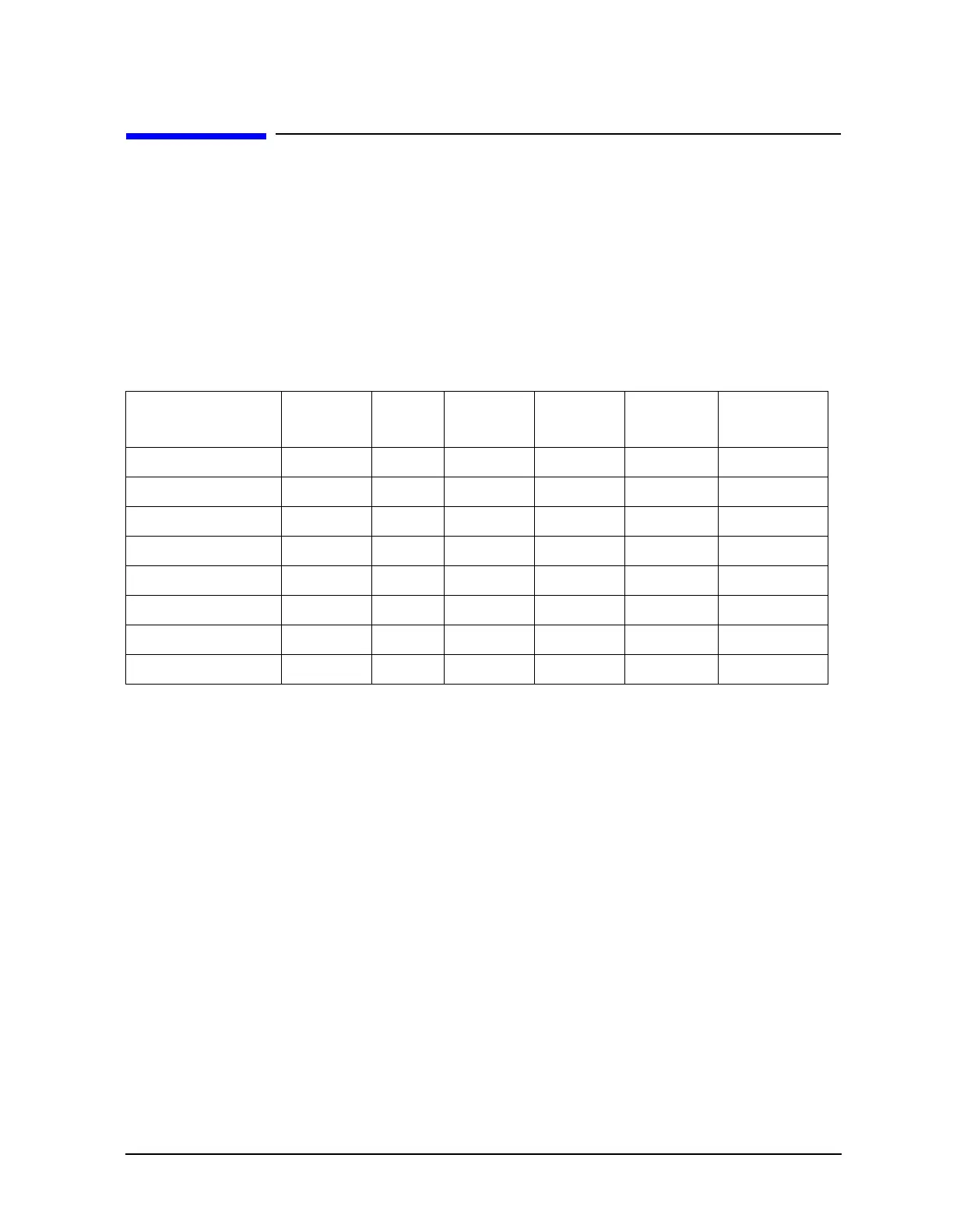

Table 9-1 Components Related to Specific Error Terms

Component Directivity Source

Match

Reflection

Tracking

Isolation Load

Match

Transmission

Tracking

Calibration Kit

load X

open/short X X

Analyzer

sampler X X X

A10 digital IF X

test port connectors X X X X X X

External cables XX

Loading...

Loading...