2 - 18

TECHNICAL DATA

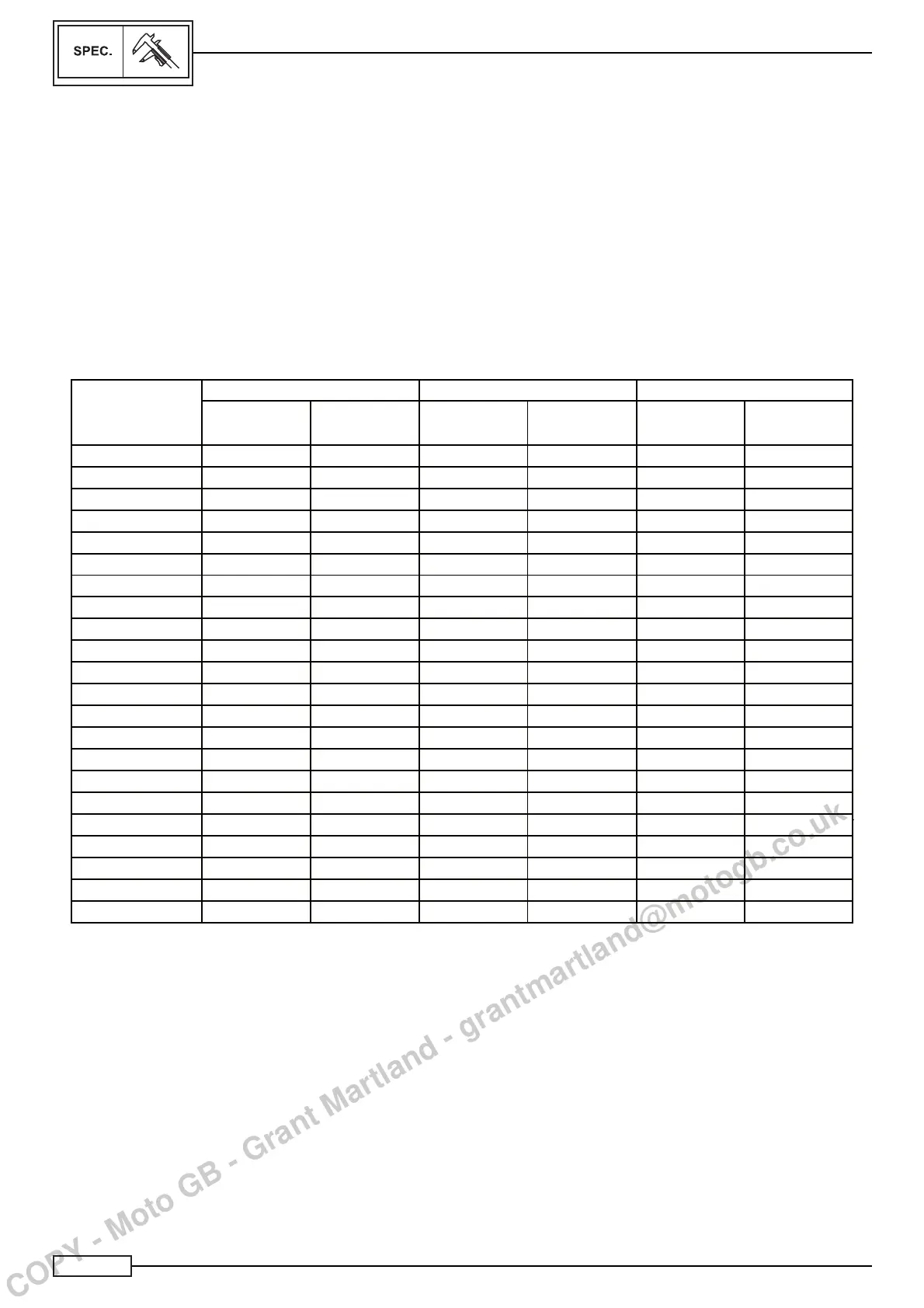

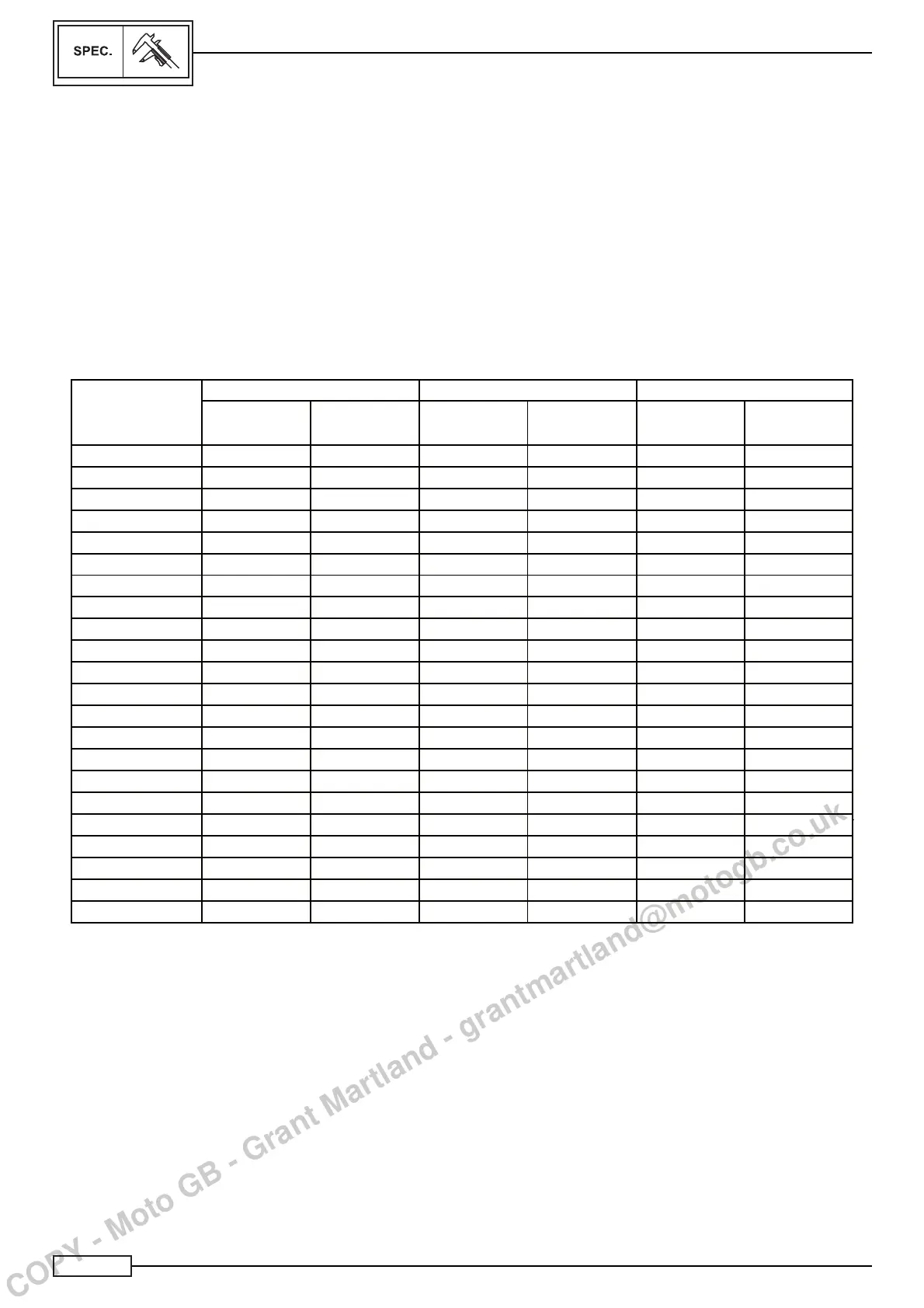

TIGHTENING TORQUES

TIGHTENING TORQUES AND RELEVANT PRELOADS FOR STANDARD CONNECTIONS

The values provided in the following table refer to standard tightness, i.e. metric screws coupled with relevant nut or with lead screw

in metal.

The parts to be tightened together must be in metal or suffi ciently rigid not to need the insertion of bushing or shims.

Coupling must always use lightly oiled or greased threads; alternatively, the type of thread lock paste required will be indicated

Axial preloads, related to tightness torques, have been increased by 10% on the calculated value to take into account the tolerance

on the nominal torque and the changes that the friction coeffi cient may undergo between tightening operations.

(*) The metric screw indicated has a fi ne pitch.

CLASS 8.8

SCREW

CLASS 10.9 CLASS 12.9

TIGHTENING

TORQUE

[Nm]

M4 X 0.7 3 3.870 4.2 5.420 5.2 6.710

M5 X 0.8 6 6.350 7.5 7.930 9 9.520

TIGHTENING

TORQUE

[Nm]

AXIAL

PRELOAD

[N]

AXIAL

PRELOAD

[N]

TIGHTENING

TORQUE

[Nm]

AXIAL

PRELOAD

[N]

M6 X 1 10 8.860 13 11.520 16 14.180

M8 X 1.25 22 14.900 30 20.330 40 27.100

M8 X 1 (*) 25 17.280 36 24.890 45 31.110

M10 X 1.5 45 24.680 65 35.640 80 43.870

M10 X 1.25 (*) 50 27.870 70 39.013 85 47.380

M12 X 1.75 80 37.640 110 51.750 135 63.510

M12 X 1.5 (*) 85 40.547 120 57.250 145 69.170

M12 X 1.25 (*) 90 43.550 130 62.900 150 72.580

M14 X 2 130 52.670 185 74.800 220 88.950

M14 X 1.5 (*) 150 62.900 205 85.960 245 102.780

M16 X 2 200 74.070 280 103.690 335 124.060

M16 X 1.5 (*) 225 86.140 310 118.680 360 137.820

M18 X 2.5 265 83.650 370 116.790 450 142.040

M18 X 1.5 (*) 320 104.900 450 147.520 550 180.300

M20 X 2.5 390 111.870 550 257.770 650 186.450

M20 X 1.5 (*) 440 130.620 630 187.020 750 222.650

M22 X 2.5 540 141.950 750 197.150 900 236.580

M22 X 1.5 (*) 600 162.750 850 230.560 1.000 271.240

M24 X 3 670 160.238 950 227.203 1.130 270.252

M24 X 2 (*) 750 184.566 1.050 258.392 1.250 307.610

COPY - Moto GB - Grant Martland - grantmartland@motogb.co.uk

Loading...

Loading...