CP60 and CP60 Plus Service Manual 2-3

Sensors

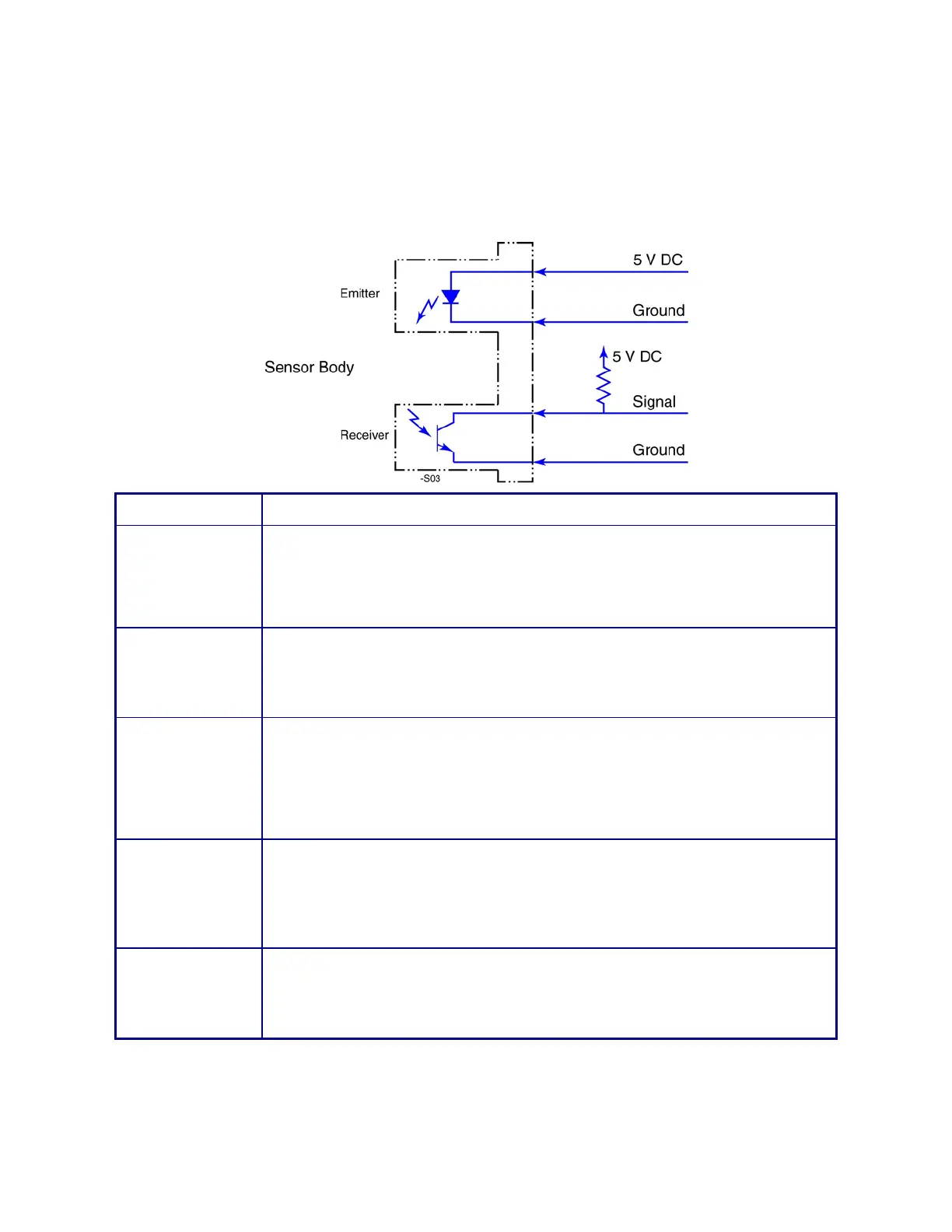

All of the optical sensors in the CP60 and CP60 Plus printers are of the open

collector type, and are configured to be active-low with a pull-up resistor on the

output. When the sensor is not active (or not connected at all) the control board

sees a high voltage (5V) at the Signal input. When the sensor is active, it shorts

Signal to Ground. The diagram below is a simplified representation of an

interruption sensor.

Name Function

Card Input

The card input sensor is an interruption sensor that detects the presence

of a card at the entry of the printer and registers the trailing edge of the

card for printing.

For the clear card option, this sensor is replaced with a reflective sensor.

Printhead Cam

As the printhead cam rotates, a flag on the cam interrupts the beam of

the cam sensor. This allows the printer to know the position of the

printhead lifters. The printhead lifters lift the printhead away from the

platen roller when not printing.

Swingarm Open

(Cover arm)

The swingarm open sensor detects when the swingarm is open. The sensor

itself detects when the swingarm is closed, but the signal is inverted

elsewhere in the system.

Note: The user information and Diagnostics refer to this as a cover arm

sensor.

Ribbon Index

The ribbon index sensor is used to determine the position of the print

ribbon panels. The sensor bounces a beam off the reflective sticker on the

printhead. When the index mark or K-panel on the ribbon passes between

the sensor and the reflector, the beam is broken (not reflected). The Y, M,

C, & T panels do not interrupt the beam.

Ribbon Motion

The ribbon motion sensor is a two-channel optical interruption sensor that

detects slots on the ribbon encoder wheel. The encoder wheel is located

on the ribbon cartridge. Internally the sensor body contains a pair of

standard interruption sensors.

Loading...

Loading...