CP60 and CP60 Plus Service Manual 2-5

Motors

The CP60 and CP60 Plus printers have up to five motors depending on the

configuration. The three DC motors are all similar, with an integral reduction

geartrain and 24-volt operation. The speed of the motors is controlled by pulse

width modulation. While the motors are reversible, some are wired to operate in

one direction only. The duplex step motor operates at 24 volts, but the transport

step motor operates at 40 volts.

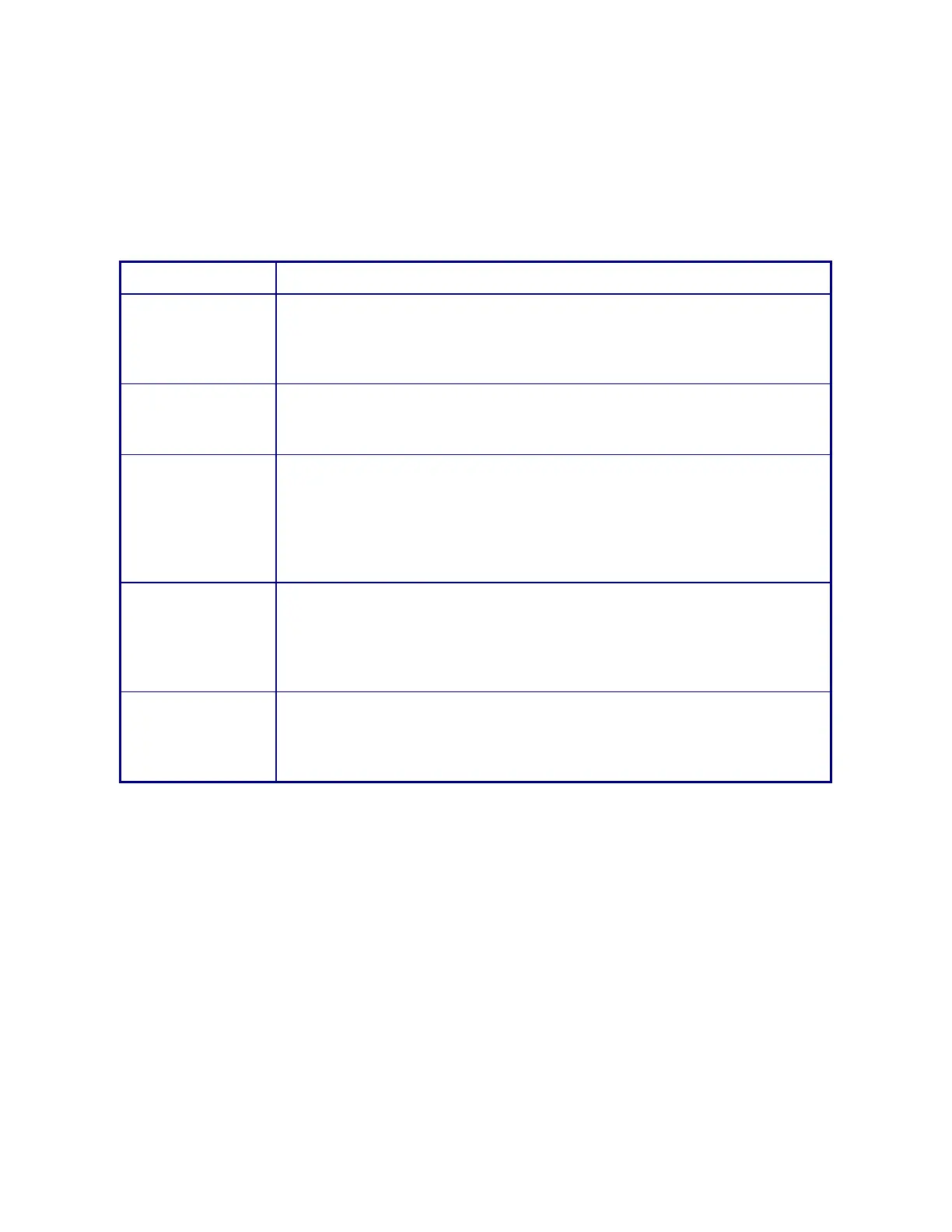

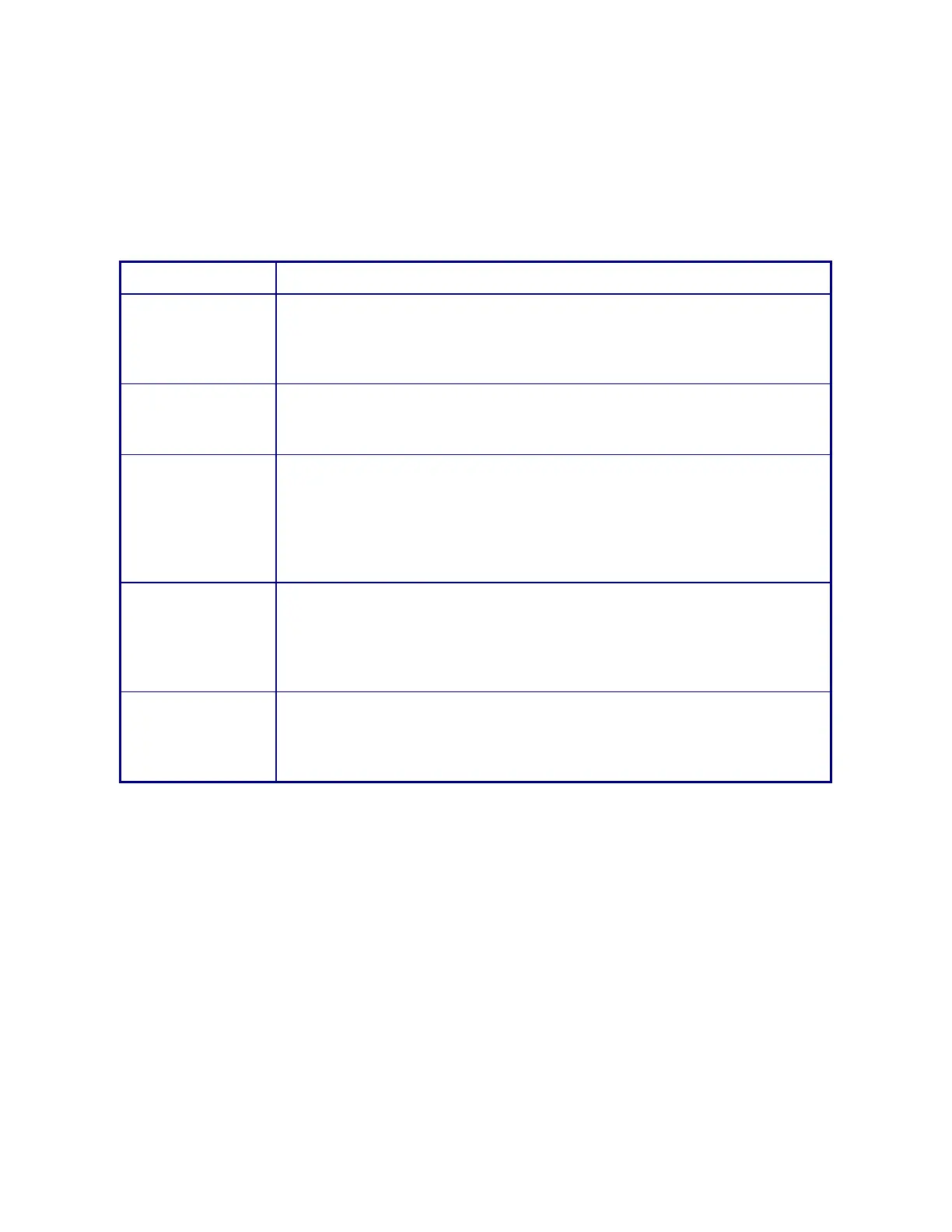

Name Function

Pick Motor

The pick motor drives the pick roller to bring a card into the system. The

motor is wired for unidirectional operation and cannot be reversed by

the control board. One wire is tied to ground and the other wire is the

control. This motor is driven by a single channel in the motor driver.

Transport Motor

The transport motor drives the platen roller through a gear, which also

drives the main transport belt. This is a 2-phase (4-wire), 40-volt stepper

motor.

Cam Motor

The cam motor rotates the printhead cam, which operates the

printhead lifters. This raises and lowers the printhead into position for

printing or permitting a card to pass beneath. This motor is wired bi-

directional and uses two channels from the motor controller so that it

can be reversed. (However at this time, the motor is not operated in

reverse.)

Ribbon Motor

The ribbon motor drives the gear train of the ribbon cartridge to

advance the ribbon during printing. The motor is wired for

unidirectional operation and cannot be reversed by the control board.

One wire is tied to ground and the other wire is the control. This motor is

driven by a single channel in the motor driver.

Duplex Motor

The duplex motor drives a gear on the duplex clutch. The clutch

permits a single motor to either operate the rollers, or rotate the entire

flipper assembly (this is discussed in more detail on page

2-6). This is a

2-phase (4-wire), 24-volt stepper motor.

Loading...

Loading...