Chapter 4 -Operational Procedures-

134

AS-410M Auto Slide Preparation System

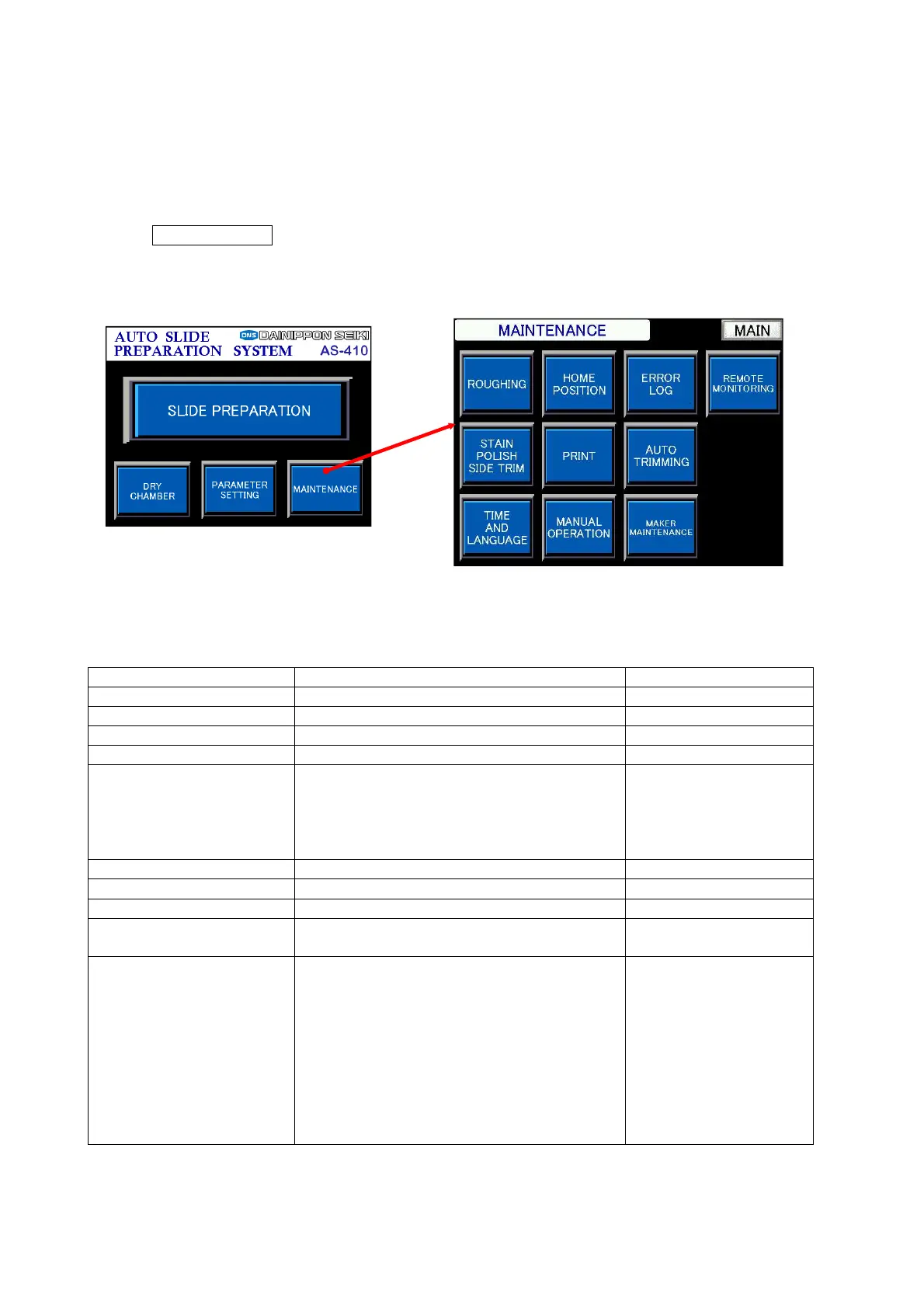

4-11 Maintenance Mode

The Maintenance Mode consists of the following sub-modes: Roughing mode for trimming block

surfaces; Home position mode for initializing the System; Stain mode for associating dyeing methods

with section thicknesses; Print mode for specifying print data items; Error log mode for viewing and

storing error log data; Time mode for setting time; Manual operation mode for manually operating the

system mechanical components individually; and Maker maintenance mode for setting the basic data

for ensuring system operational integrity.

Touch MAINTENANCE on the “Main” screen to enable the Maintenance Mode.

This Chapter guides the User through the operational steps for rough-cutting, initialization, staining

data, printer settings, error log, time set, and manual operation. This Operating Manual does not cover

the Maker maintenance mode.

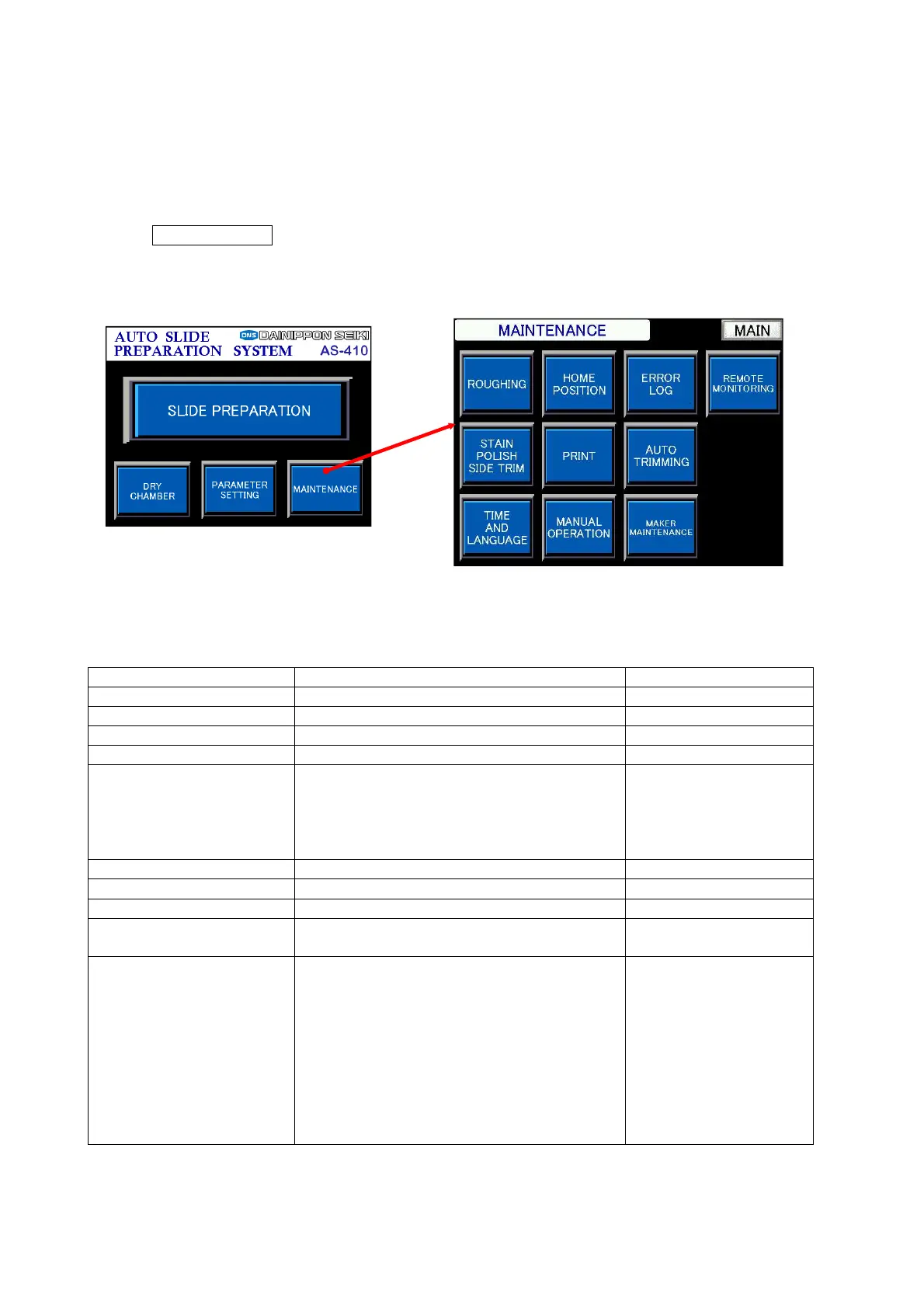

Table 4-9: Sub-modes of the Maintenance Mode

Sub-mode Intended purpose Remarks

ROUGHING Performing block surface trimming only.

HOME POSITION Initialization

ERROR LOG Viewing and storing error log data.

REMOTE MONITORING Setting E-mail message destinations

STAIN/ POLISH/ SIDE

TRIM

Associating stain types with section

thickness.

Setting the maximum and minimum value

for polishing.

Setting the side trim function.

PRINT Selecting and deselecting print data items.

AUTO TRIMMING Operational settings for Auto trimming

TIME AND LANGUAGE Changing time and language displayed

MANUAL OPERATION

Manually operating the moving components

of the System individually.

MAKER MAINTENANCE Maintenance by the manufacturer

Password-protected to

prevent the User from

making changes to the

settings. A system

breakdown caused by

any unauthorized

changes to the settings

invalidates the

manufacturer’s

warranty.

MAIN screen

Maintenance mode screen

Loading...

Loading...