Chapter 4 -Operational Procedures-

136

AS-410M Auto Slide Preparation System

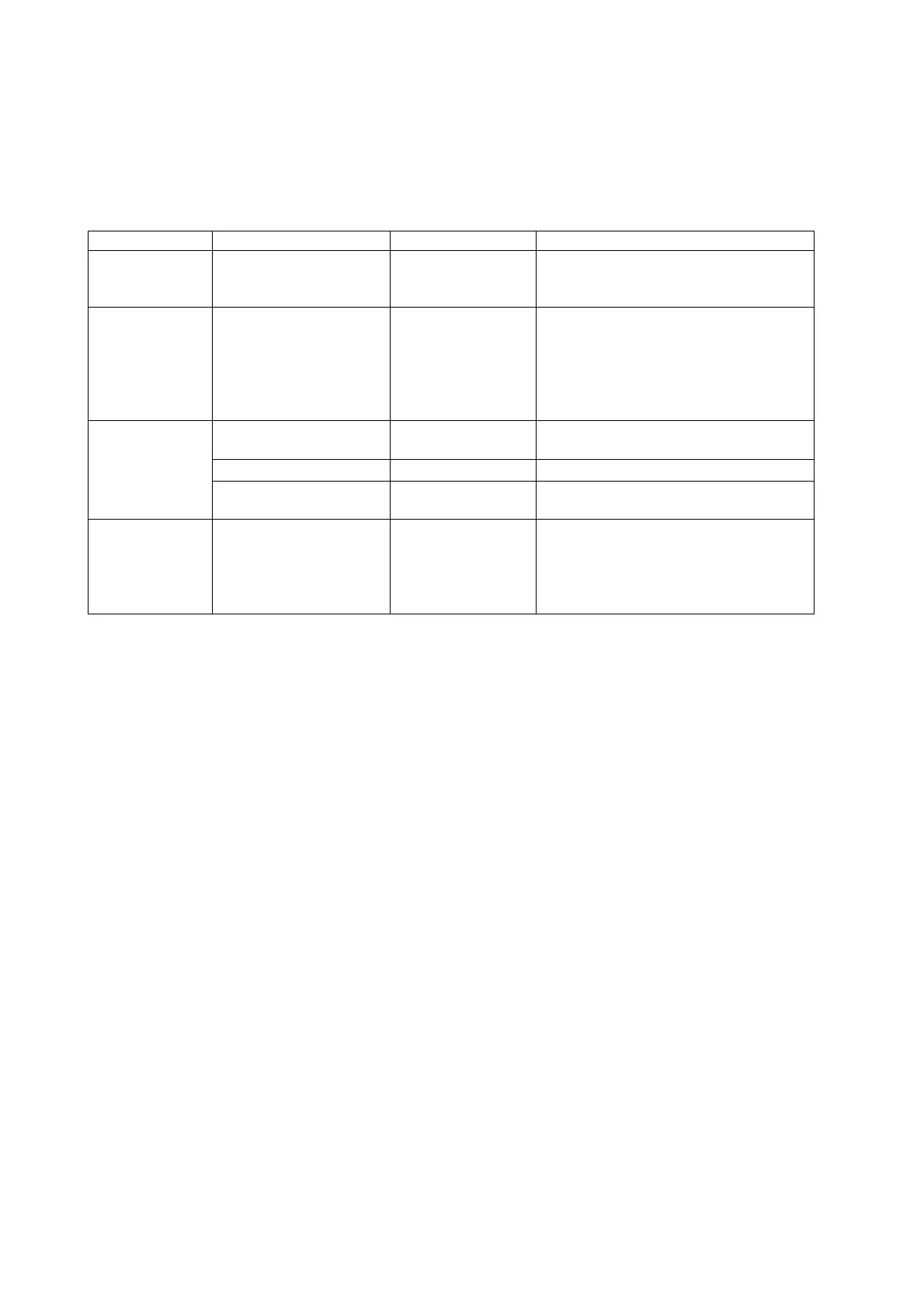

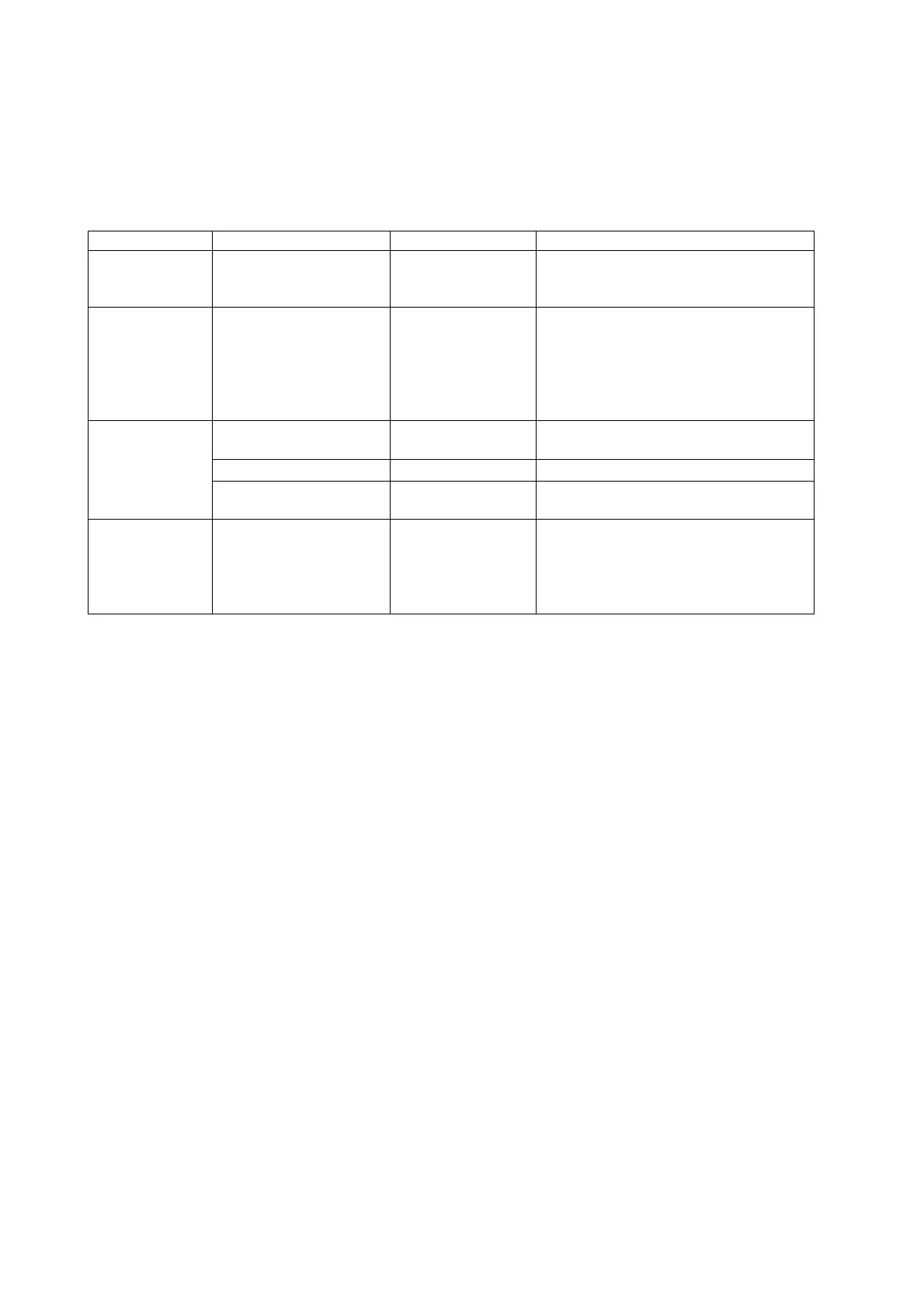

4-12-1 Roughing parameters

Table 4-10 lists parameters available during the roughing. Select the microtome blade operation

mode and the surface angle adjustment method. Specify the sectioning thickness per cut and the

number of sections to define the roughing depth from the sample surface. Select whether to attach

thin sliced sections to the carrier tape during the roughing.

Table 4-10: Rough-cutting parameters

Screen to use

Parameter type Operation Parameters

Slicing

Parameter

Settings

Slicing parameter

Slicing parameter

file selection

1. Slicing speed

2. Knife pull angle (90° or 60°)

Sample Block

Positions

Sample tray and

position on it

1. Specify a tray and a sample

position on it.

2. Select all samples on the

specified tray.

3. Deselect all samples on the

specified tray.

Roughing

Condition

Settings

Slicing thickness

Slicing thickness

per cut

2 to 30

μ

m (increments of 1

μ

m)

(Recommended: 15

μ

m or less)

Number of sections

1 to 999 cuts

Humidifying

Sample

moistening

1. ON (moistening enabled)

2. OFF (moistening disabled)

Roughing

1. Attach sections to

carrier tape.

2. Abort roughing.

3. Pause roughing.

Check thin sliced

sections to

ensure they each

contain a tissue

slice.

After section attachment to the

carrier tape with Option 1 selected.

The System will automatically pause

itself

4-12-2 Outline of the operation and the preoperational setup

Refer to 4-13-3 “Outline of the roughing operation.”

As preparatory works before power-on, set sample blocks and the waste liquid tank in place (refer

to 3-4 and 3-8, respectively). Depending on the condition settings, the humidifying water bottle and

the carrier tape must be set in place (refer to 3-6 and 3-12, respectively). In roughing operation, slides,

slide collection boxes, and application medium are not necessary.

Loading...

Loading...