Chapter 4 -Operational Procedures-

96

AS-410M Auto Slide Preparation System

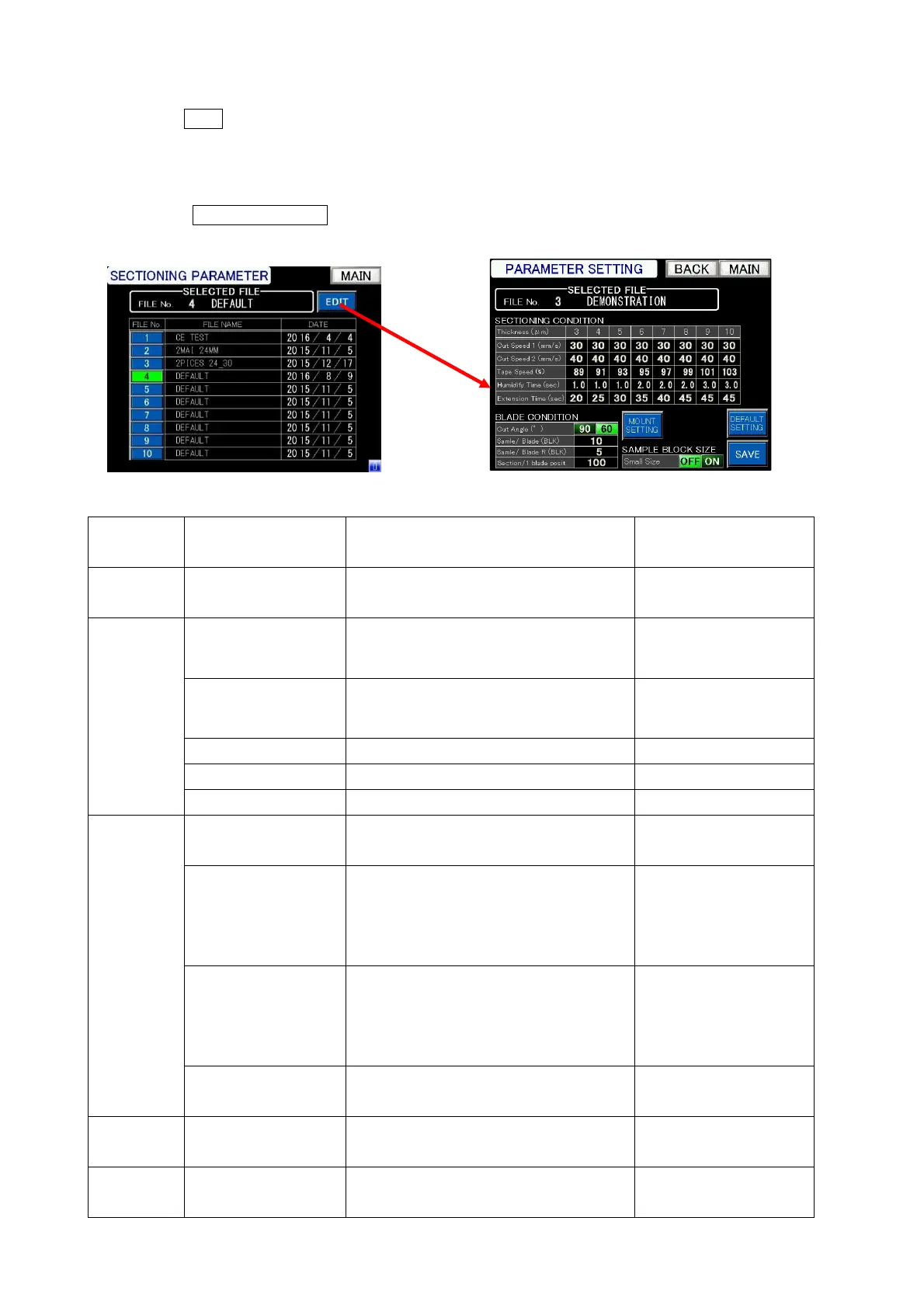

4-3-2 Editing the sectioning parameters

① Touch EDIT on the “SECTIONING PARAMETER” screen to go to the “PARAMETER SETTING”

screen. Then, the data contained in the currently loaded file will appear on the screen. Refer to

Table 4-3 and use the Operation Panel to make necessary changes to the sectioning parameter

settings.

Touch MOUNT SETTING to set the application medium dripping position/dripping amount and

slice mounting position in each file.

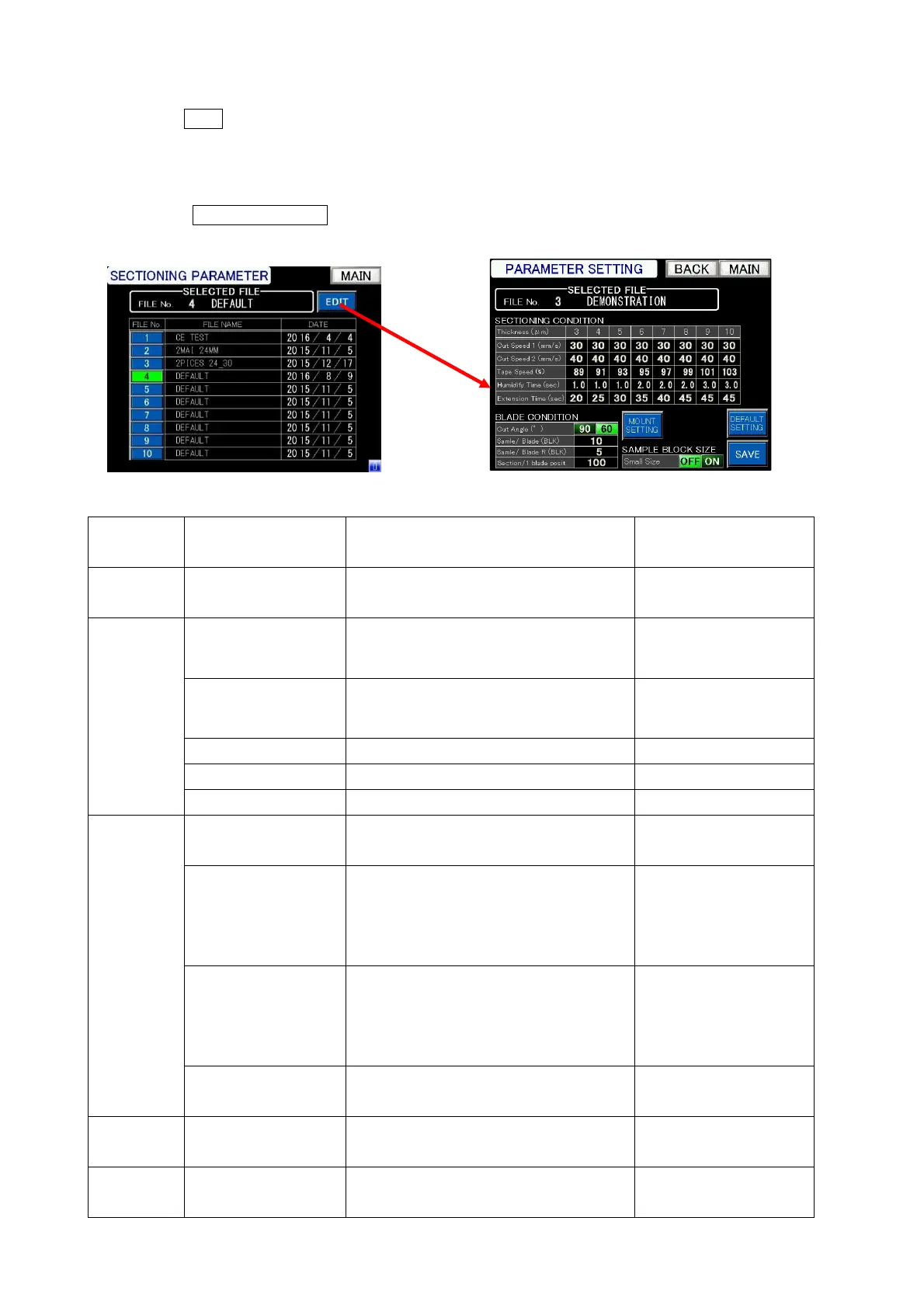

Table 4-3: Details of sectioning parameter settings

On-screen

item

Setting item

Description

Setting range

Selected

File

Current File

The file No. and file name of the currently

opened file appear here.

File Nos. 1 to 10

Selected

Condition

Cutting speed

Cutting speed selected to attach sections to

the tape

Knife pull angle

90°: 5 to 99 (mm/sec)

60°: 5 to 80 (mm/sec)

Cutting speed

(no section attachment)

Cutting speed selected to skip attaching

sections to the tape

Knife pull angle

90°: 5 to 99 (mm/sec)

60°: 5 to 80 (mm/sec)

Tape speed Tape speed relative to sectioning speed 70 to110 (%)

Humidifying time Duration of pre-sectioning moistening 0.1~60 (sec)

Extension time Duration of stretching sections on a slide 1~99 (sec)

Blade

Movement

Pull angle

Specify here the knife pull angle set for

sectioning.

90° or 60°

Samples (blocks) /knife

Specify here the number of blocks to be

sliced per knife during section slide

preparation involving neither rough-cutting

nor surface detection.

1 to 96

Samples (blocks) /knife

(R)

Specify here the number of blocks to be

sliced per knife during section slide

preparation involving rough-cutting or

surface detection.

1 to 96

Sections/one position

Specify here the max. number of sections to

be prepared per knife position.

1 to 400

Block Size

Small sized sample

(block)

Select “ON” to perform sectioning based on

the block height measurement only.

Default

Setting

Current data file is updated in File No. 10

Parameter setting screen

Slicing parameter setting screen

Loading...

Loading...