Chapter 4 - Operational Procedures -

AS-410M Auto Slide Preparation System

133

4-10-4 Checking the section slide quality and collecting section slides

Touch UNLOCK DOORS to open the front door(s) of the dry chamber to check the finished quality

of stored section slides, i.e., adhesion failure and dryness of sections.

[Operational procedure]

① Turn OFF the System power and open the front door of each dry chamber. Take out the

collection box from the shelf and check the finished quality of section slides on the slide

trays.

② When the slide preparation is completed, remove section slides from the slide trays and

store them.

③ Collect samples from the sample trays.

④ In the case of any half-dry sections or if it is necessary to perform the slide preparation again

to cover a shortfall due to defective sections, return the collection box back on the shelf.

Removal of a collection box with the system power ON will result in deletion of the

number of stored-slides data. When it is necessary to start slicing with half-dry slides

loaded inside, be sure to read and follow the data entry instructions in this section.

When it is necessary to remove a collection box, use great care to avoid dropping it.

●

When it is necessary to check the condition of section slides on the slide trays,

use great care to avoid inadvertently changing the order of stored slides. For

example, always check one tray

⑥

①

②

③

④

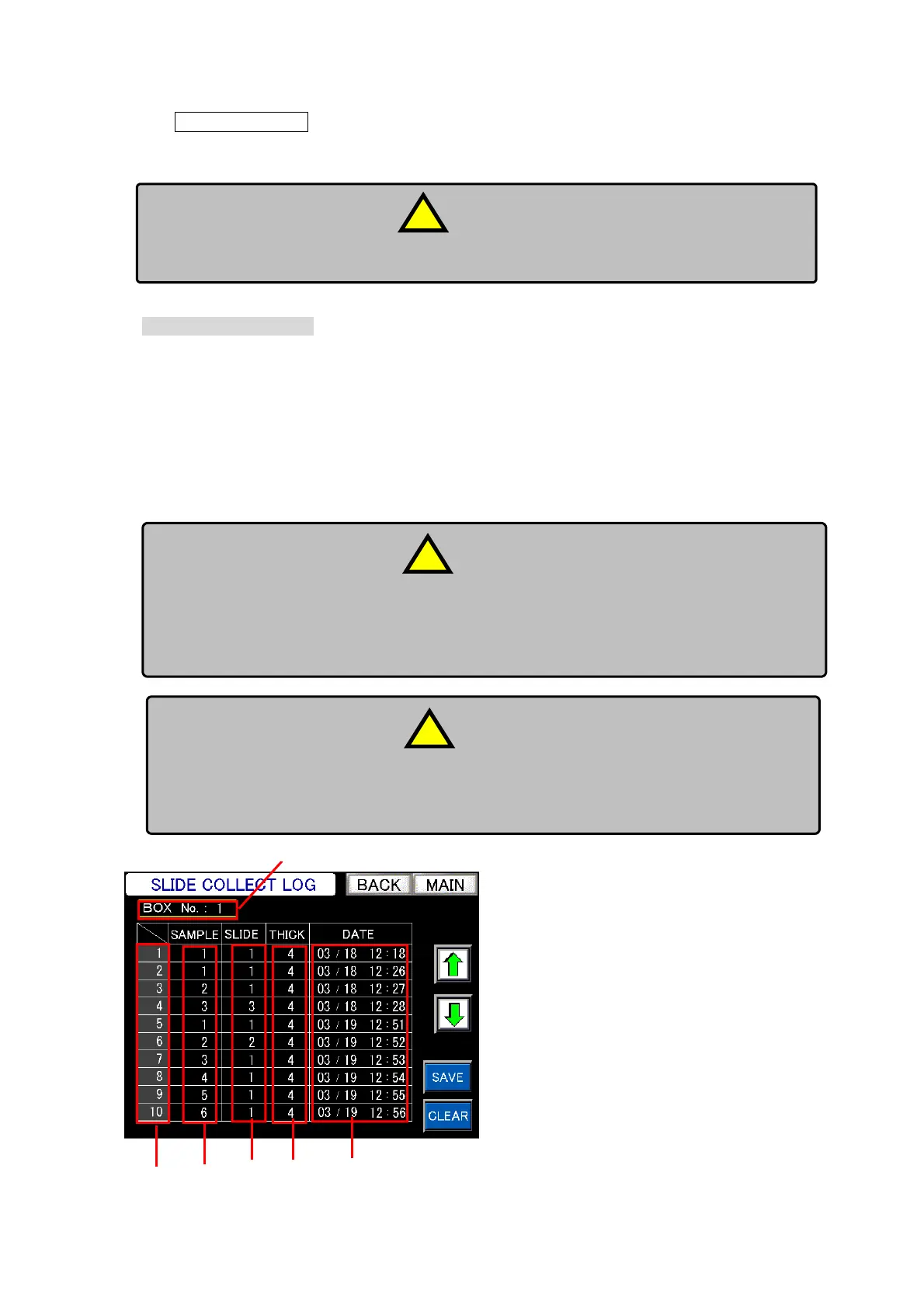

Storage log data items:

① Address Nos. in slide collection box (1 to 100)

② Sample Nos. of processed samples

③ Number of slides from the same samples.

④ Slicing thickness (μm)

⑤ Month, date, hours and minutes at which slides

were stored in the collection box

⑥ Slide collection box No. (System with DU-400)

⑤

! Caution

! Caution

! Caution

Loading...

Loading...