Chapter 4 - Operational Procedures -

AS-410M Auto Slide Preparation System

93

4-2 Operational parameters

The AS-410M uses [Operational Parameters] that must be selected for each run.

Table 4-2 shows the outline of the [Operational Parameters] available.

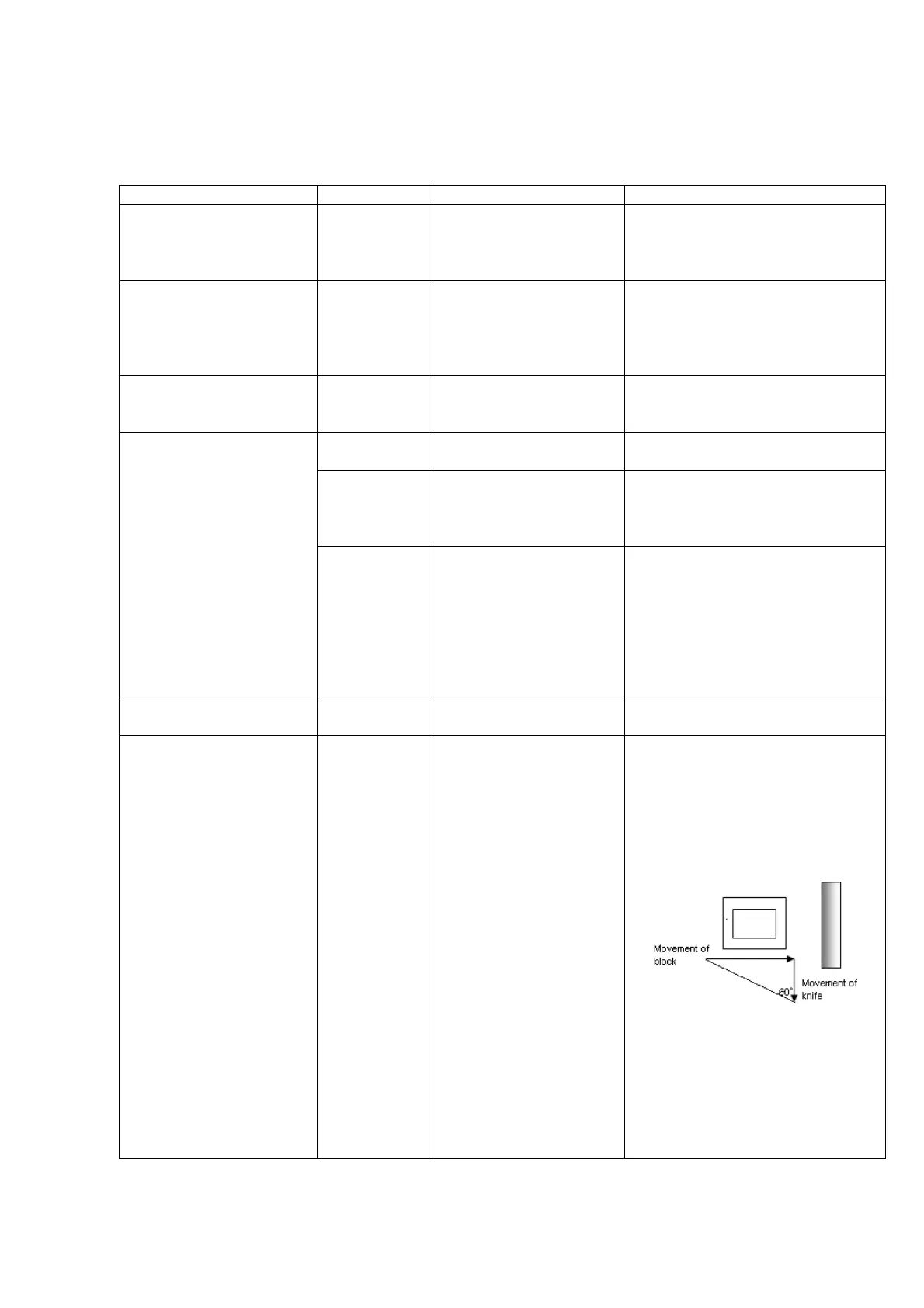

Table 4-2: [Operational Parameters] used for section slide preparation

Item Parameter Descriptions Selection item

Sample block positions Block

position on

sample tray

1. Block position

2. Tray number

(Applicable only to System with

BS-96)

Slide storage location Storage

location of

finished

slides

Specify the slide

collection box No. and

the slide tray No. for

storing the 1st section

slide.

1. Slide tray No.

2. Slide collection box No.

(Applicable only to System with

DU-400)

Slide

(* System with 400-slide

Feeding unit option)

Slide type

Sectioning conditions

Slicing

thickness

Thickness of section

sliced

3 to 10

μ

m

(increments of 1

μ

m)

Number of

sections

Number of slices per

block

System with DU-100

1 to 100 slices

System with DU-400

1 to 400 slices

Rough-

cutting

Rough cutting conditions

for section slide

preparation

(Rough-cutting may be

skipped in some cases.)

1. Rough-cutting thickness

Rough-cutting thickness per

cut:

3 to 30

μ

m in increments of 1

μ

m

2. Number of cuts:

0 to 999

(Select “0” to skip rough-cutting.)

Stretching (extension) Specify the duration of

extension.

1 to 99 seconds

Method of using

microtome blade

Select the cut angle.

Max. number of blocks

to be sliced per

microtome blade.

Max. number of slices

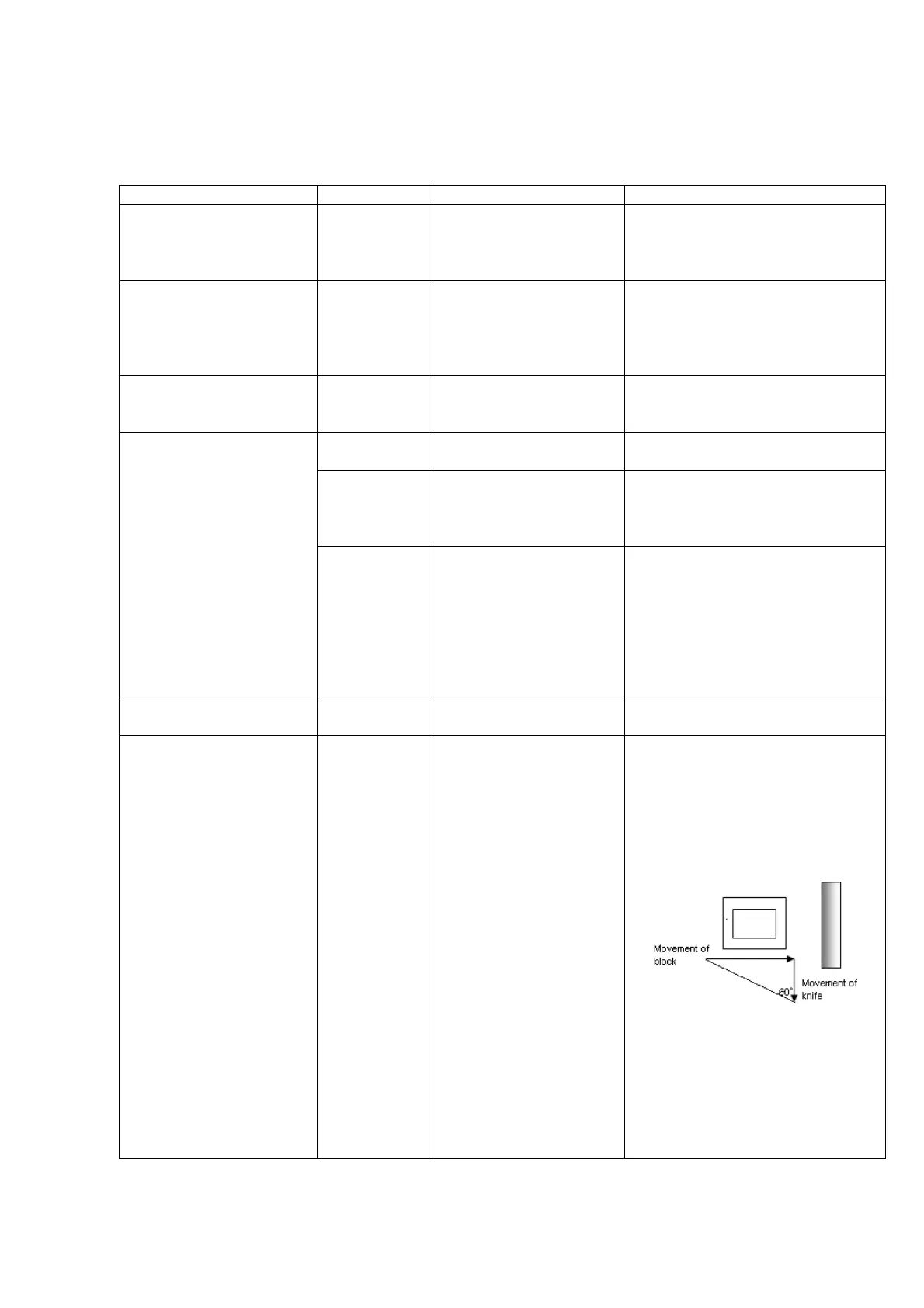

1. Select 90° or 60°.

Select 90° to cut sections

without moving the blade.

Select 60° to cut sections with

the blade moving as shown

below:

2. Max. number of blocks to be

sliced when skipping rough-

cutting.

3. Max. number of blocks to be

sliced after rough-cutting.

4. Max. number of slices per

sectioning position.

Loading...

Loading...