Chapter 3 -Preoperational Setup-

78

AS-410M Auto Slide Preparation System

3-17 Starting and exiting the Auto Surface Detection application

To use the Auto Surface Detection function with the System AS-410M, the parameter setting of the Auto

Surface Detection application must be setup before run. Please refer to 4-20 for parameter setting. All of

the sample blocks will be processed under the same setting conditions of Auto Surface Detection

application.

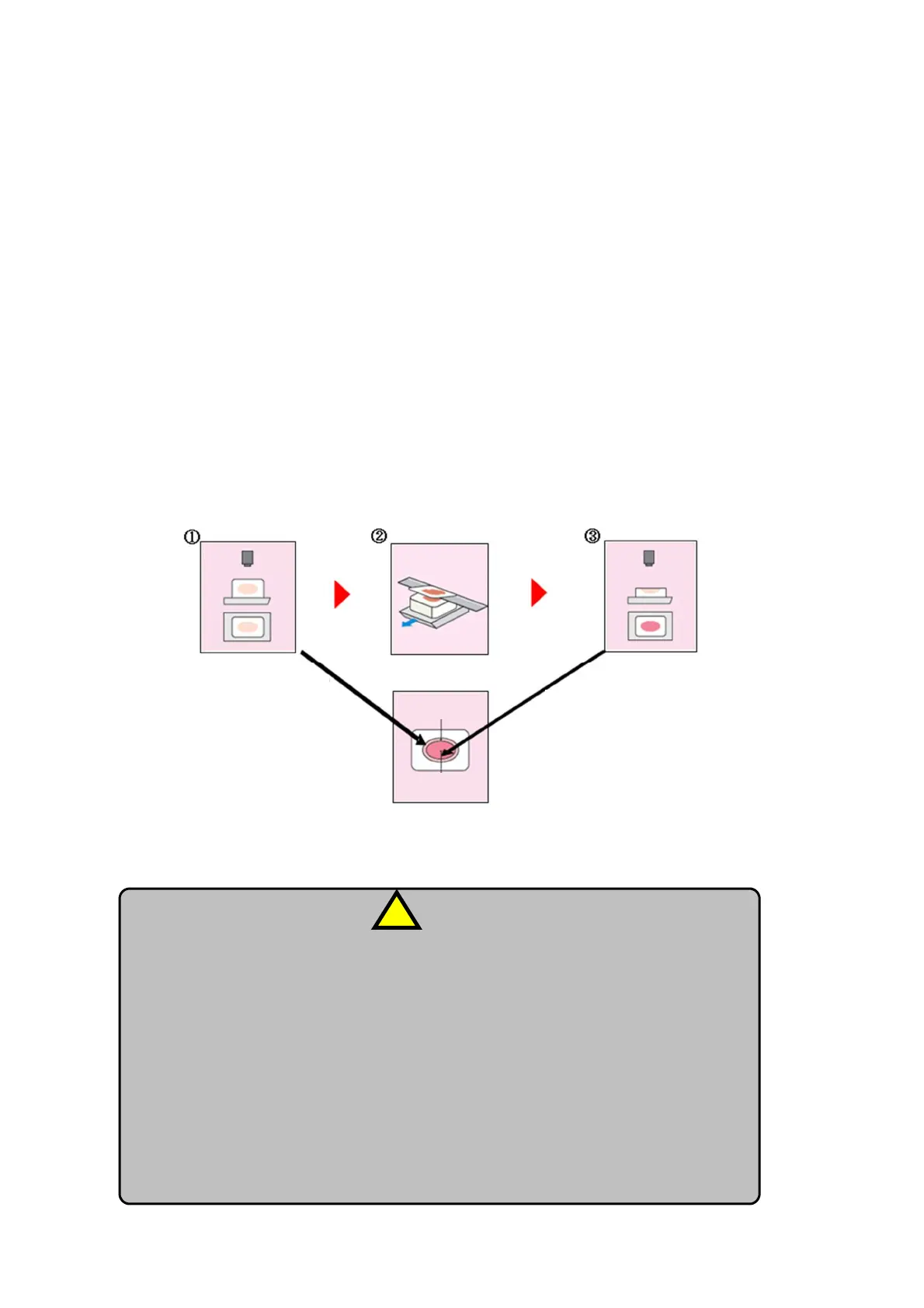

Auto Surface Detection application detects the sample surface by following procedure.

① Capture the image from the upper side of the sample block before rough-cutting. Detect entire

tissue area (maximum embedded tissue area) from the image.

② Start rough cut (auto trimming).

③ Capture the image after rough cut. Detect and analyze the exposed tissue area on paraffin surface

from the image.

Auto Surface Detection Application calculates percentage of surface detection ratio (%) of tissue

specimen area on paraffin surface (③) compare to the entire tissue specimen area (①). If the

percentage does not reach to criteria, repeat the trimming (rough cut) and measure percent ratio. (If

the surface detection ratio (①) value exceeded the threshold, machine starts the tissue slide

making.)

The parameter for Auto Trimming (rough cutting) function is in parameter setting screen on the auto

trimming.

・

Tilting mechanism does not work with the Auto Trimming function.

・

Samples in following conditions are not suitable for Auto Surface Detection

application.

1. Color of the tissue specimen similar to the color of paraffin or paraffin

cassette.

2. Tissue surface is not parallel to paraffin surface.

3. Tissue thickness is less than 5mm.

4. Multiple tissues are embedded at different height in single paraffin block.

5. Large gap between the tissue size observed from upper side and tissue

size on paraffin surface. Example: tube form

CCD

CAMERA

embedded area

Maximum

Tissue area

surfaced

tissue area

!

Note

Loading...

Loading...