031914 M3-5

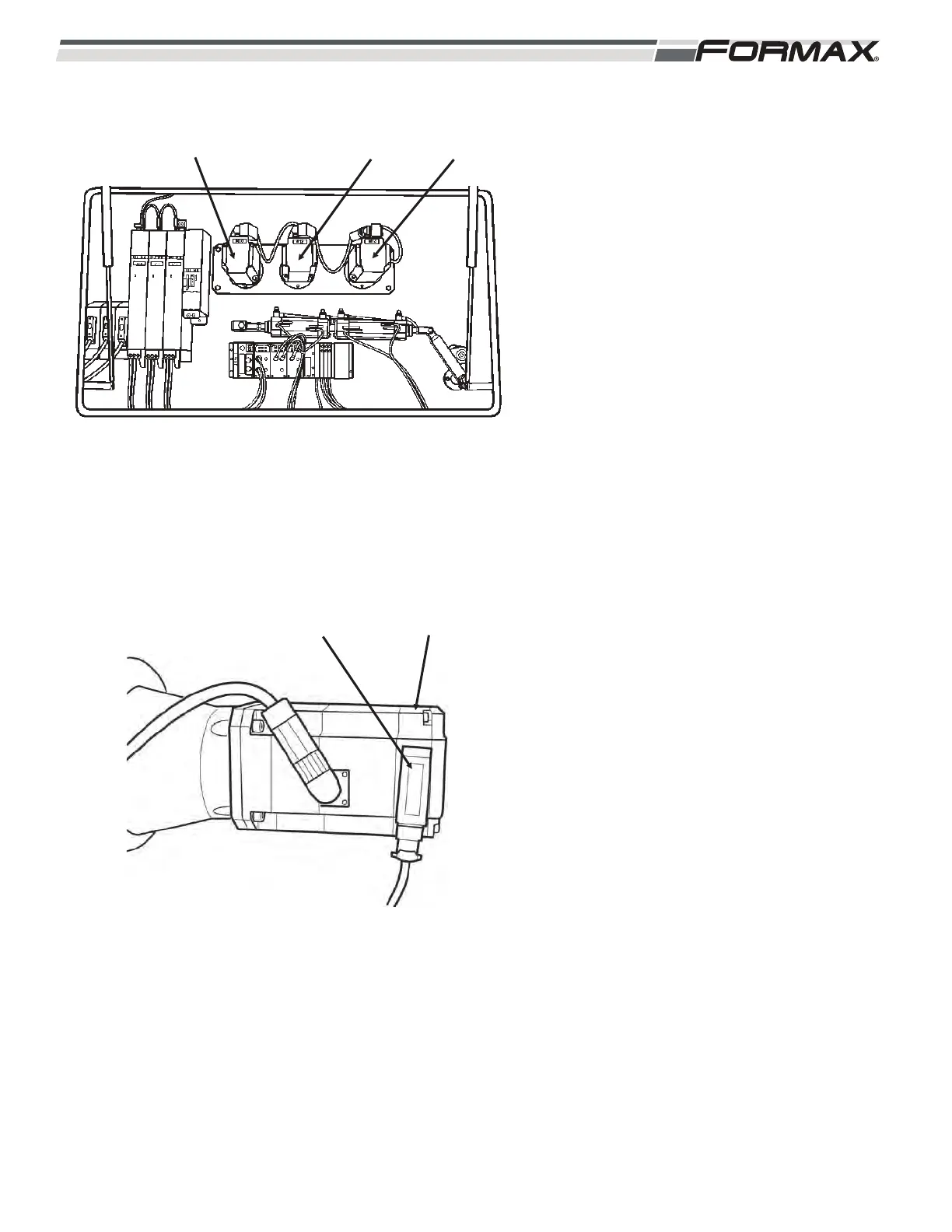

SERVO MOTORS: Each motor has a built in

Resolver Feedback System that tells the Motion

Control Modules the exact speed, direction and

position of the Servo Motor. (Illustration 9) The

Motion Control Modules use this information to

send control information to the Servo Drives that

control the Servo Motors. There is a Thermistor

located in the windings of each motor. The

Thermistor helps to protect the motor from a

thermal overload. An “Over Temperature” Fault

is generated when the internal temperature of

the motor exceeds 170° C (338° F). The “Knife”

Servo Motor is equipped with an optional

holding brake. This Brake is used to hold the

Knife stationary whenever a "Master Off" button

is pressed. It is not used during a normal "Cycle

Stop." The Structure Lift Servo Motor is also

equipped with an internal Brake that engages to

hold them stationary when a “Master Off” button

is pressed.

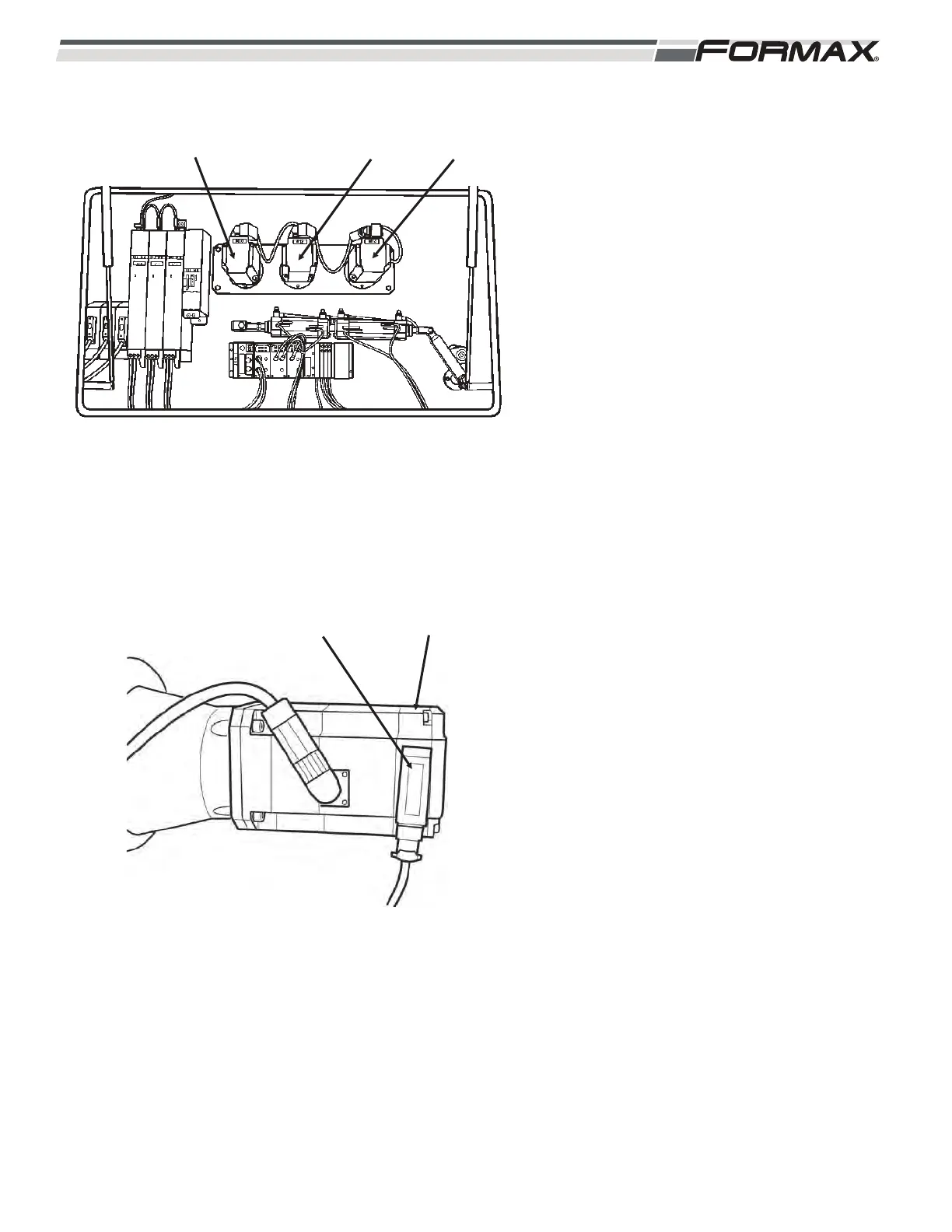

RESOLVER FEEDBACK SYSTEM

Each Servo Motor has a built in “Resolver

Feedback” system. A Resolver is a rotating

transformer that creates sinusoidal signals (Sine

and Cosine), that relate to the shaft position of

the Servo Motor. These signals are sent to the

Motion Control Modules and determine the

“absolute motor position.” The Motion Control

Modules use the Resolver Feedback signals

generated by the Servo Motors to monitor and

control the Servo Drives and the Servo Motors.

ILLUSTRATION 10

RESOLVER FEEDBACK CABLE RESOLVER

M10

SERVO

MOTOR

M12

SERVO

MOTOR

M14

SERVO

MOTOR

ILLUSTRATION 9

Loading...

Loading...