# OF STACKS/DRAFTS: The total number of stacks or

drafts sliced during the production run.

# OF ACCEPTED: The total number of stacks that were

accepted for being “On-Weight.” The “accepted” range is

determined by the “+/-“ tolerances of the Target Weight.

# OF REJECTED: The total number of stacks that were

rejected as being “Off-Weight.” These stacks our out of the

“accepted” range.

TOTAL WEIGHT (Kg): The combined weight of all of the

stacks or drafts that were run.

AVERAGE STACKS / LOAF: The total stacks/drafts

produced are averaged for each loaf.

AVERAGE ACCEPTED WEIGHT (gm): The average

weight of the accepted stacks.

% ACCEPTED: The number of accepted stacks divided by

the total number of stacks.

% REJECTED: The number of rejected stacks divided by

the total number of stacks.

% GIVEAWAY: The “Average Stack Weight” divided by the

“Target Eight.”

ACCEPTED WEIGHT (Kg): The total weight of the

accepted stacks.

OFF WEIGHT (Kg): The total weight of the rejected stacks.

AVERAGE SLICE THICKNESS (mm): The “Average Slice

Thickness” of the accepted stacks or drafts. This is

continuously updated as the stack or drafts are weighed.

WEIGHT STANDARD DEVIATION (gm): “Weight Standard

Deviation” displays the range of the lightest and heaviest

weights that fall out of the “Accepted Weight Range.”

START SLICE THICKNESS: Displays the average slice

thickness of the first slice in each stack.

RUNNING TIME: Displays the total time that the Knife is

spinning, while the current Product Code is selected.

PRODUCTION TIME: Displays the total time that the

“Feed” button is “On” and product is slicing.

PRODUCTION RATE: Displays the “Stacks/Drafts per

minute” of the Slicer. The “Production Rate” is determined

by the Knife Speed and the Slice Denial setting.

AVG. RELOAD TIME: The average amount of time from

the end of one loaf until the machine starts slicing the next

loaf.

031914 6-35

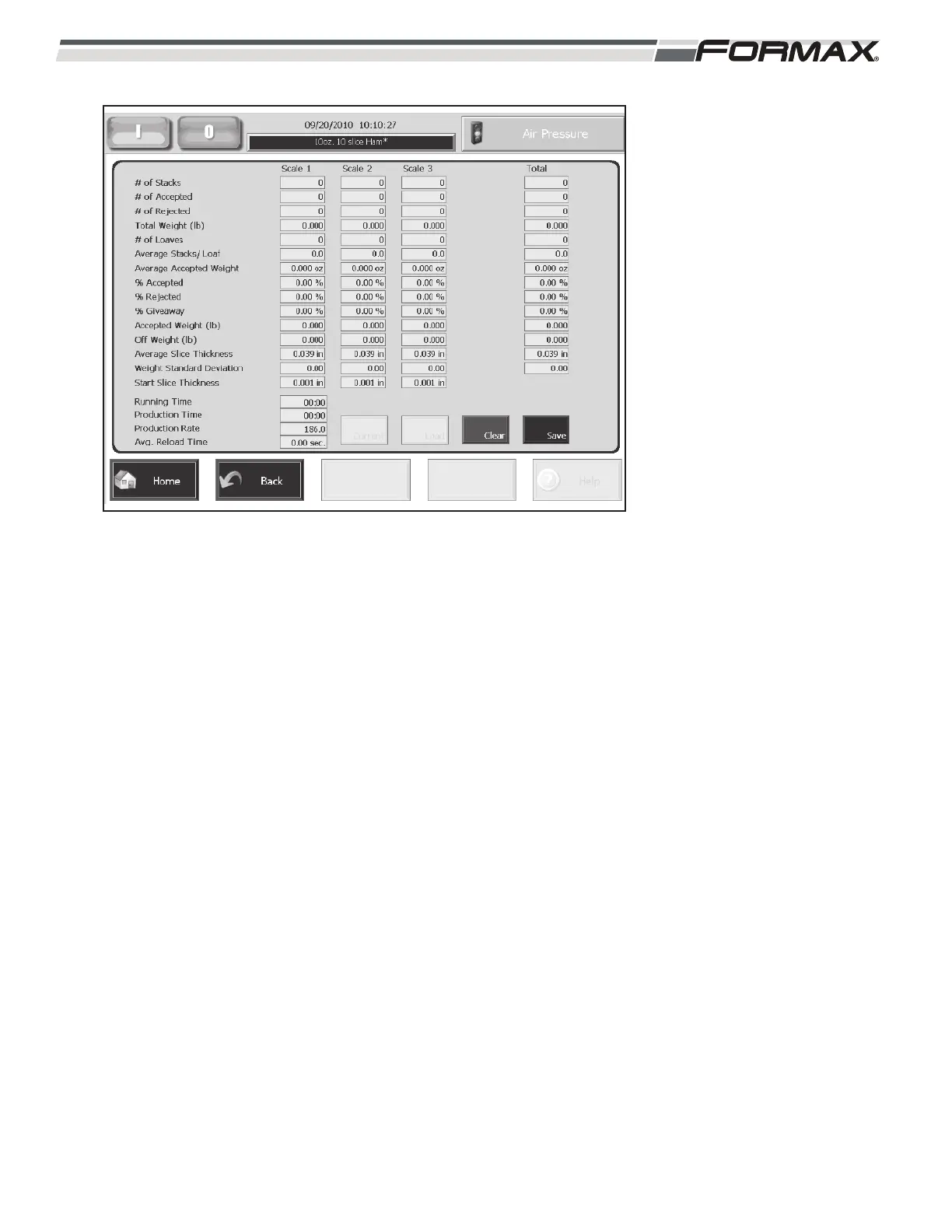

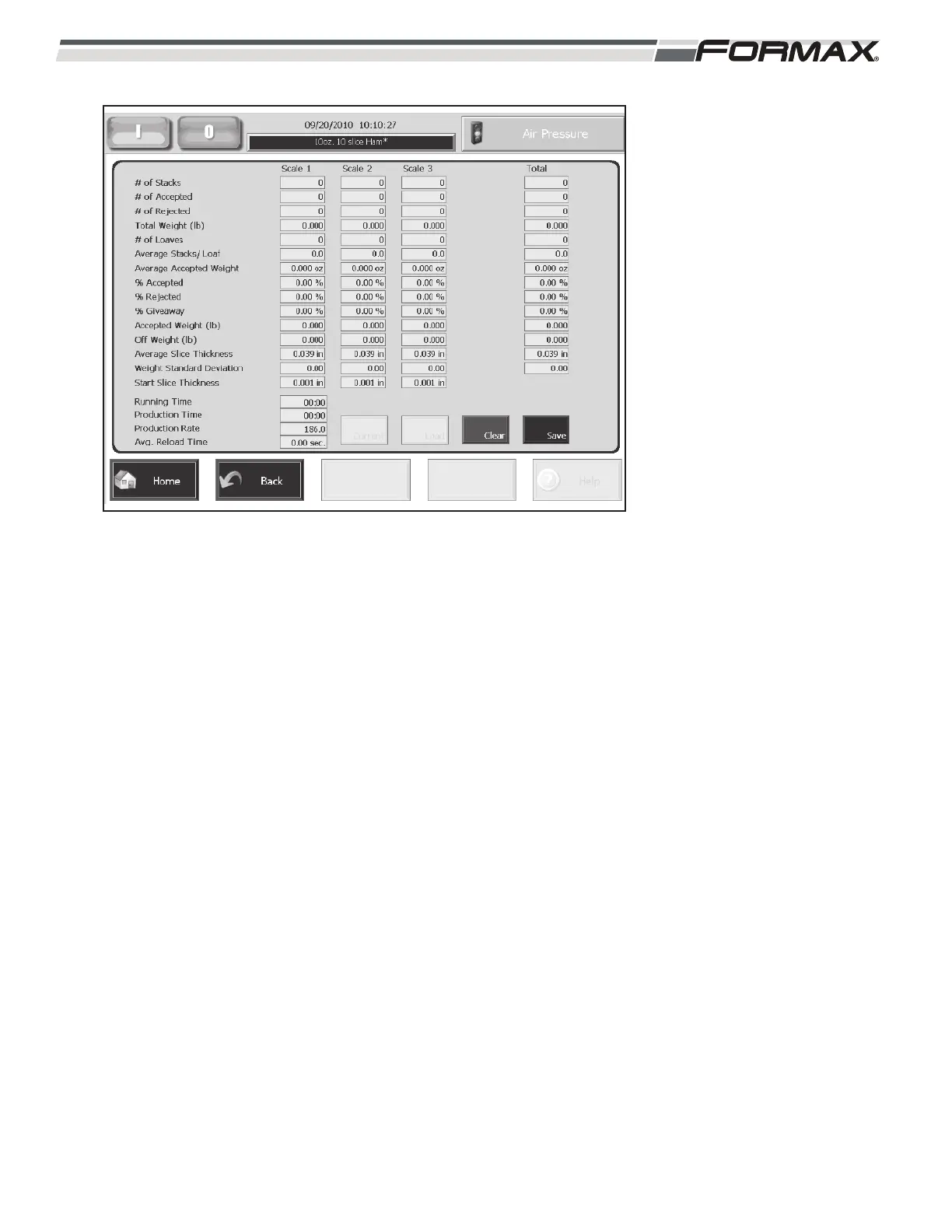

ILLUSTRATION 93

PRODUCTION DATA

SCREEN

To access the Production

Data screen, touch the

“Production Data” button on

the “Home” screen.

(Illustration 93) The

“Production Data” screen

displays the production

output of the Slicer for each

Product Code. The output

from each of the Dynamic

Scales is monitored and

displays on this screen. The

accumulated total of all of the

Scales, also displays.

Loading...

Loading...