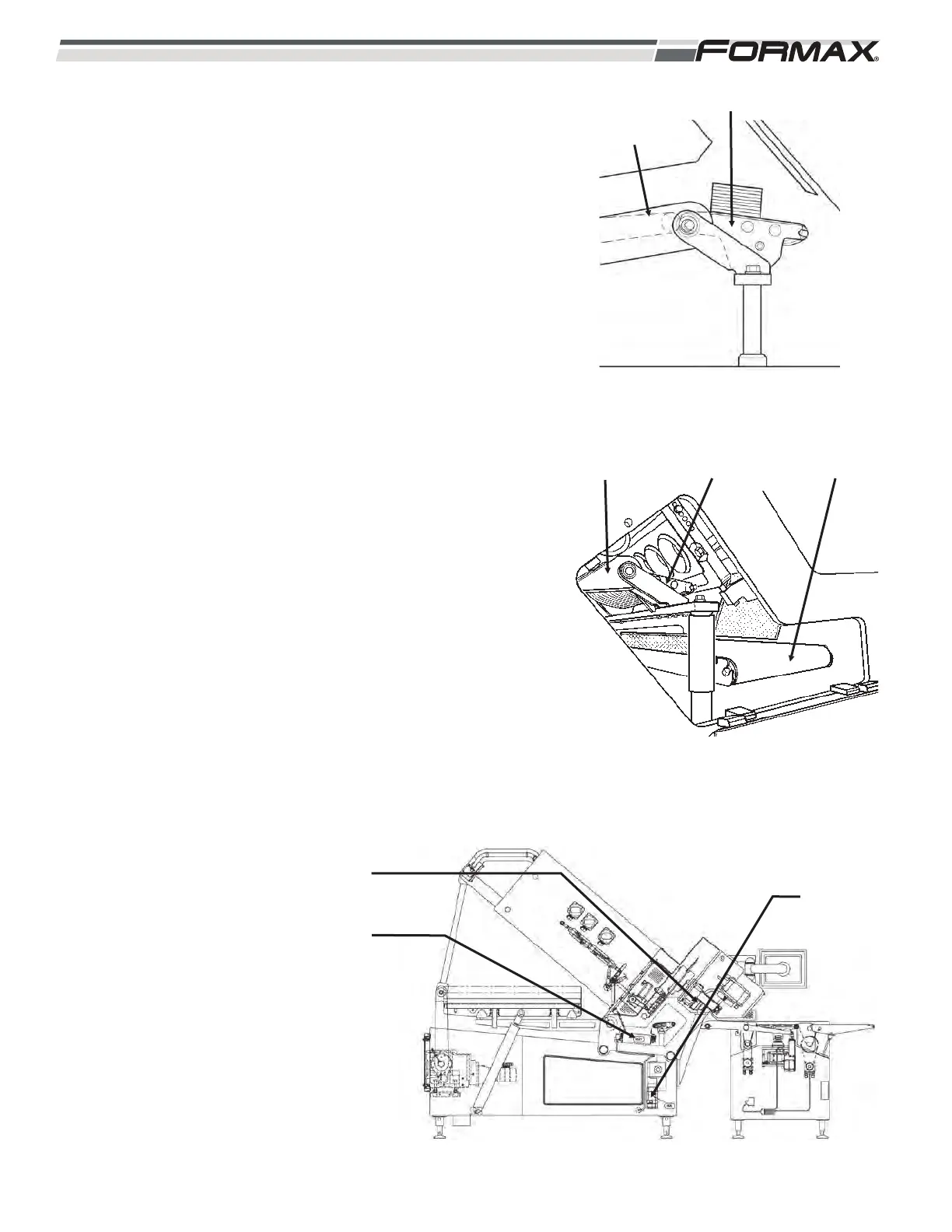

SLICING CONVEYOR: The product is sliced onto the Slicing

Conveyor and then transfers to the Transfer Conveyor.

(Illustration 23)

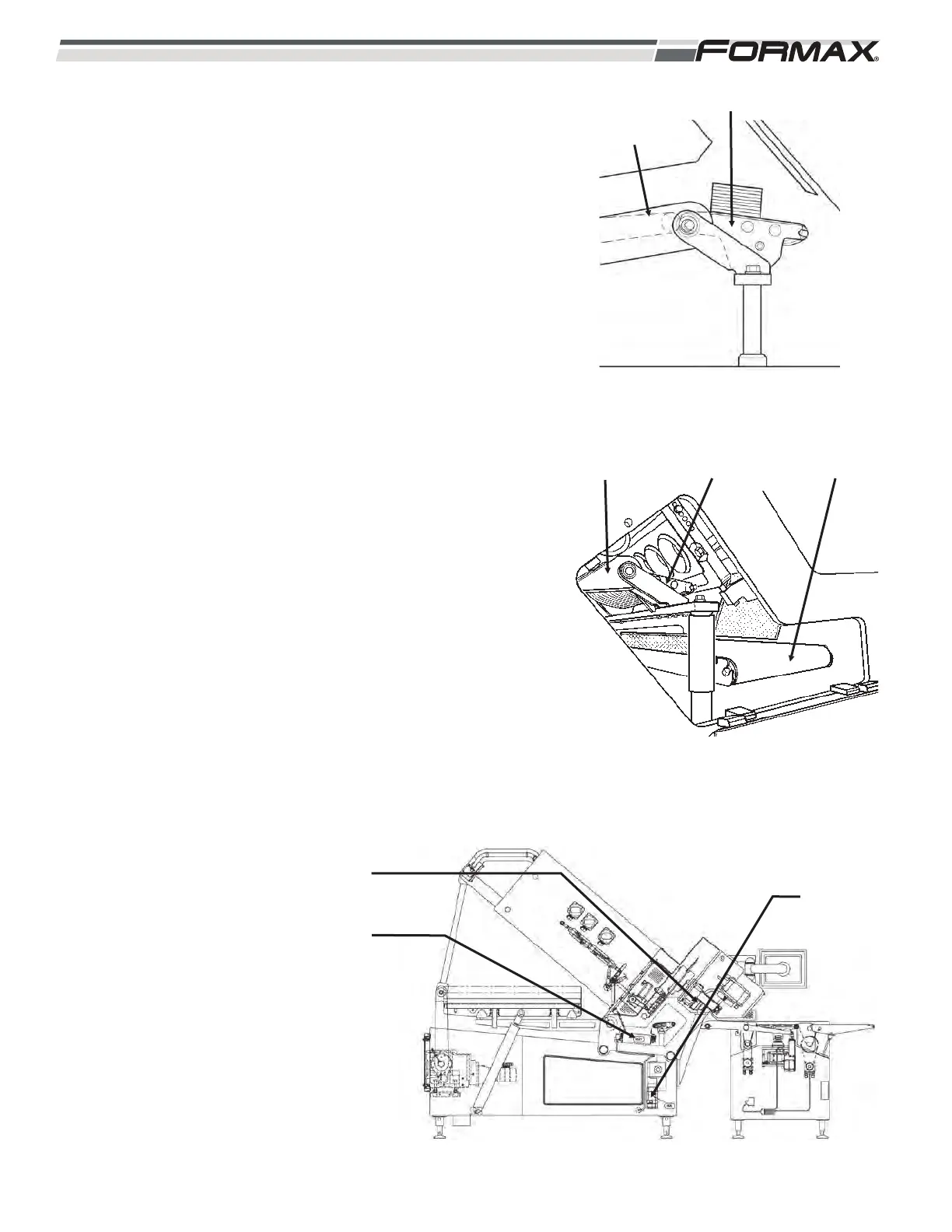

SLICING CONVEYOR: The “Slicing” Conveyor travels to the top of

its travel at the start of the stack or draft and lowers as the stack is

created. The up and down travel is controlled by the M4 Stacker

Motor and is belt driven. The U6 Servo Drive controls the M4 Servo

Motor. (Illustration 25)

The “Slicing” Conveyor transfers the finished stack to the Transfer

Conveyor. When shingling product, the Slicing Conveyor slowly

travels forward to create the shingle of the slices. The speed of the

conveyor when it transfers the product is adjustable on the

“Adjustments” screen. There is a separate adjustment that controls

the travel distance of the conveyor during the shingling process. The

Slicing Conveyor is driven by the M3 Servo Motor when it transfers

the product off. The M3 Servo Motor drives a planetary gearbox that

in turn drives 2 reciprocating gearboxes with a belt and pullies. The

Slicing Conveyor drive shaft attaches directly to the output shaft of

the lower gearbox. As the M3 Servo Motor drives the series of

gears, the Slicing Conveyor turns. The M3 Servo Motor is controlled

by the U5 Servo Drive.

DEBRIS CONVEYOR: The “Debris” Conveyor Belt is located under

the product slicing area and runs at a slow speed whenever product

is slicing. (Illustration 24) The Debris Conveyor catches the End

Butts and any scrap created as the Knife slices the product and

transfers it into a tub. The Debris Conveyor is driven by the M21

Drum Motor. The M21 motor is a standard 3-phase AC motor. When

the Computer energizes the KM2 Contactor, the M21 Motor runs.

2-10 031914

SLICING CONVEYOR

ILLUSTRATION 23

TRANSFER

CONVEYOR

ILLUSTRATION 24

DEBRIS

CONVEYOR

TRANSFER

CONVEYOR

SLICING

CONVEYOR

ILLUSTRATION 25

M3

SERVO MOTOR

M21

DRUM MOTOR

M4

STACKER

MOTOR

Loading...

Loading...