Operating Instructions • Thermal Transfer Printer TT4030 • 06-2017 • 031-93478

Technical Specifications

24

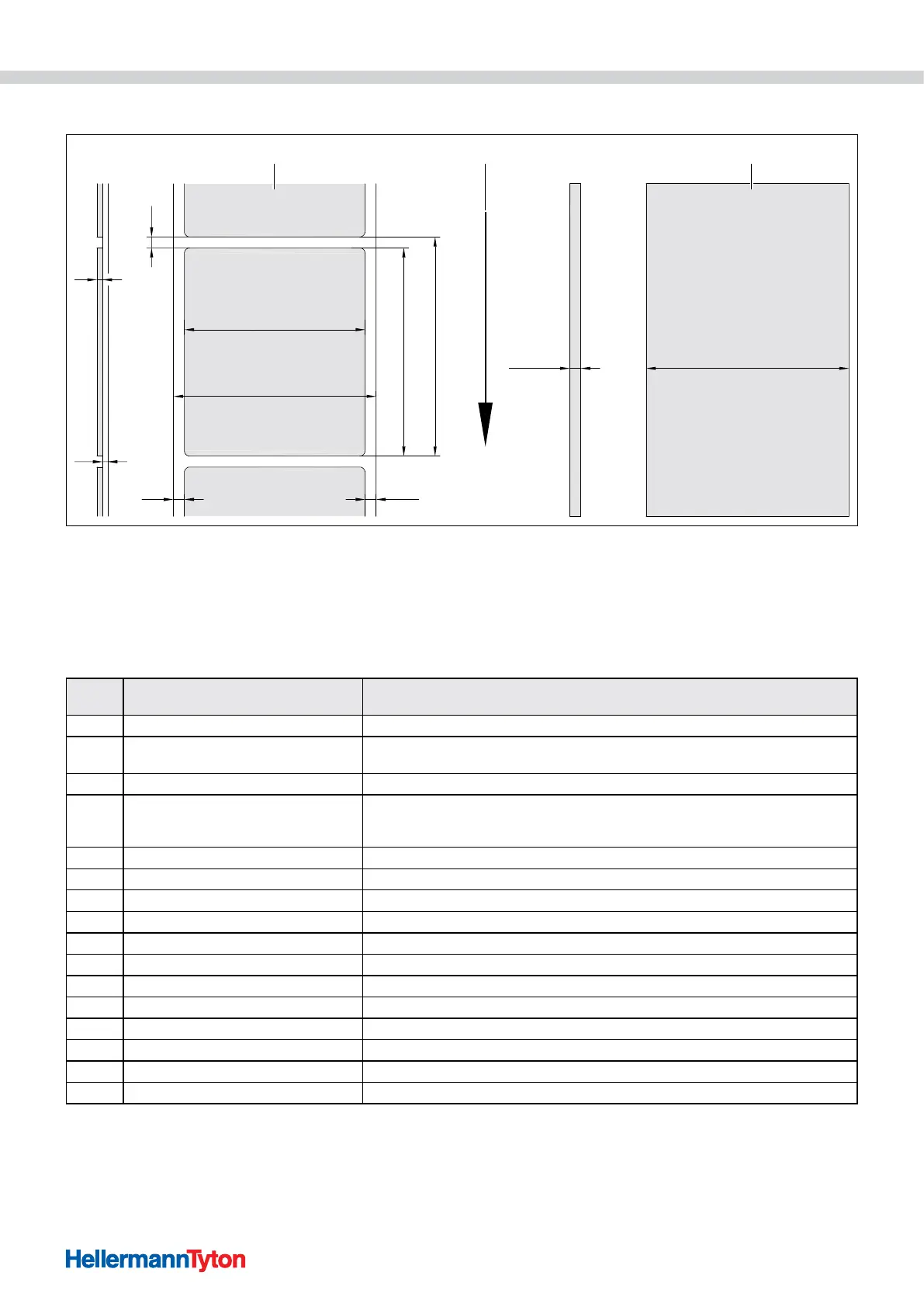

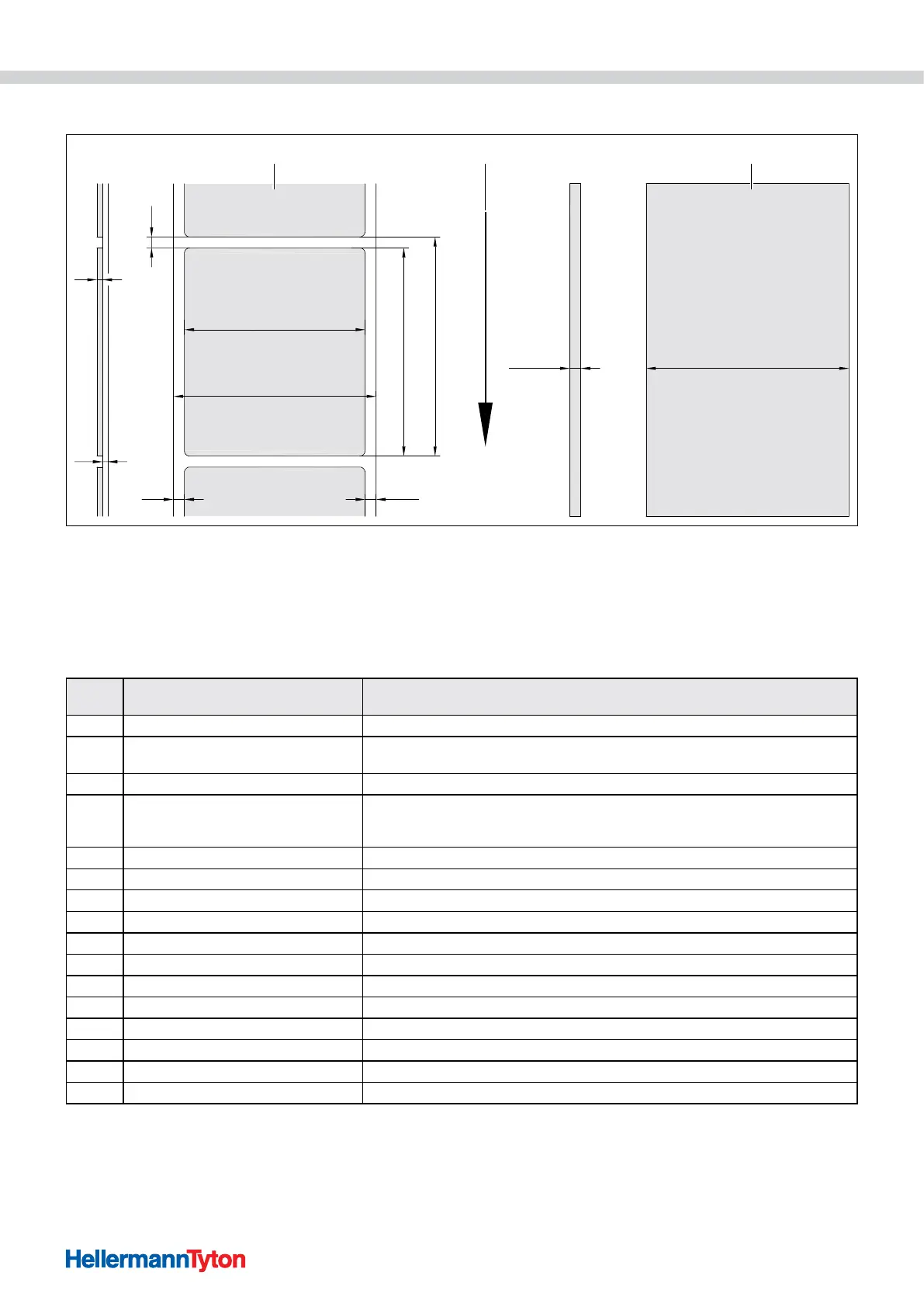

12.2 Sections/continuous material dimensions

QE/QS

(A)

E

F

DL

(DR)

B

C

HV

GE/GS

1 32

Sections/continuous material dimensions.

1 Materials

2 Feed direction

3 Continuous material/heat-shrink tubing

With small and thin materials or strong adhesives, there can be limitations. Critical uses must be tested and approved.

f Observe the bending stiffness The material must be able to follow the print roller.

Dimen-

sion

Designation Dimension in mm

B Material width 4 - 110

H

Material height

in dispensing mode

4 - 2000

12 - 200

- Tear-off length > 30

-

Cut length

with cutter

with perforation cutter

> 5

> 5

- Perforation length > 2

A Material distance > 2

C Wide carrier material 9 - 114

GE Continuous material width 4 - 114

GS Wide heat-shrink tubing 4 - 85

DL Left margin ≥ 0

DR Right margin ≥ 0

E Material thickness 0.03 - 0.60

F Carrier material thickness 0.03 - 0.13

QE Continuous material thickness 0.05 - 0.50

QS Heat-shrink tubing thickness ≤ 1.1

V Feed > 6

Loading...

Loading...