REPAIR INSTRUCTIONS, PART 1

Page 193

CUTTING THE COUNTERBORE

Refer back to Figure 190.

Measure each counterbore depth as the recut is

being performed. The goal is to provide a depth

where only a single shim is necessary to obtain

the proper cylinder sleeve stand-up height.

1. Fill the oil fill tube with 30W nondetergent oil

to maintain lubrication during use.

2. Back off the lower depth-set collar two

increments or less, and tighten the

thumbscrew securely.

3. Cut the counterbore by turning the T-handle

clockwise while maintaining constant

downward pressure on the tool. Stop the

handle in a different position to avoid

creating a ridge in the counterbore.

4. Continue backing off the lower depth-set

collar, no more than two graduations per cut.

Check the depth measurement between

each adjustment. Plan to remove 0.001 inch

(0.025 mm) on the final cut to meet the final

predetermined counterbore depth. This

ensures achieving a very fine machined

finish.

5. Remove the tool from the cylinder bore.

a. Loosen the two cutter bit hold-down

capscrews and rotate the cutter bit

adjusting screw counterclockwise until

the cutter bit is retracted into the cutter

plate.

b. Remove the four machine hold-down

bolts and special washers.

c. Remove the tool from the cylinder bore.

6. Follow steps 1 through 5 for the remaining

cylinders.

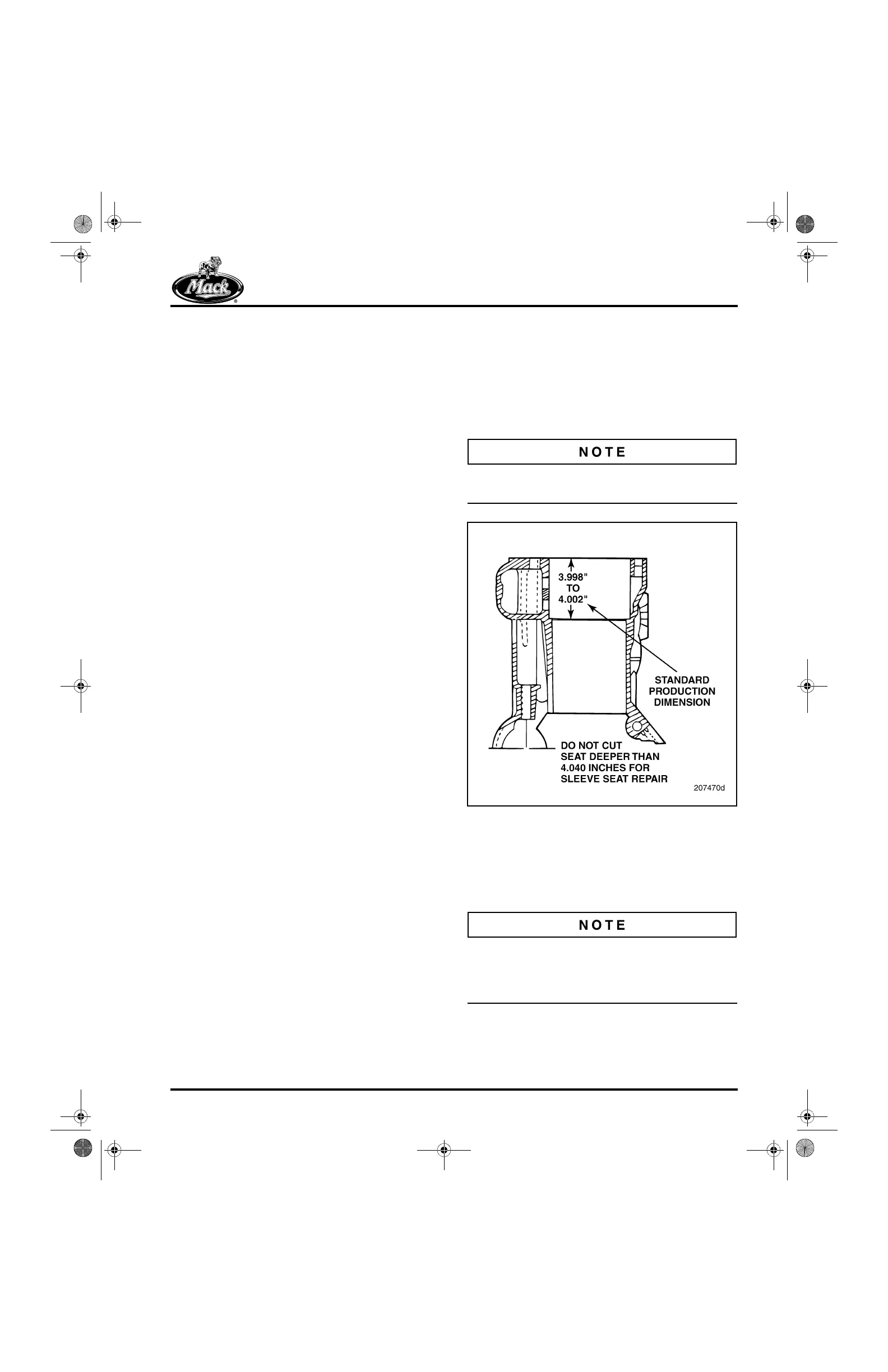

COUNTERBORE DEPTH MEASUREMENT

Measure the counterbore depth (Figure 191) and

calculate the shims needed to obtain proper

cylinder sleeve stand-up height. Single shim

repairs should be performed whenever possible.

Shims can be ordered through the MACK Parts

System using part Nos. 505GC26P2, P3 ,P4,

P10, P12, P14, P20, P31 and P42. The shim “P”

number signifies shim thickness, i.e., P14 is

0.014-inch thick. The only exceptions to this are

the P30 which is 0.031″ and P40 which is actually

0.042″. When installing shims, always use the

thickest shims and the least amount of shims as

possible to obtain the proper sleeve stand-up

height. Use a single shim whenever possible, and

if it is necessary to use more than a single shim,

use the fewest shims possible. Also because very

thin shims can be displaced, avoid the use of the

0.002, 0.003 and 0.004 shim sizes whenever

possible.

The current standard production counterbore

depth is 3.998–4.002 inches.

191

Figure 191 — Counterbore Depth Measurement

Effective March 2004, the nominal inside

diameter of all the shims was reduced by 0.064″

(1.625 mm) (from 5.225″ [132.715 mm] to 5.161″

[131.089 mm]). This change allows for a better fit

between the shim and the liner.

If necessary, it is acceptable to use a combination

of shims having the 5.225″ (132.715 mm) and the

5.161″ (131.089 mm) inside diameters on the

same sleeve seat.

5-111.bk Page 193 Monday, July 10, 2006 2:26 PM

Loading...

Loading...