Page 220

REPAIR INSTRUCTIONS, PART 1

227

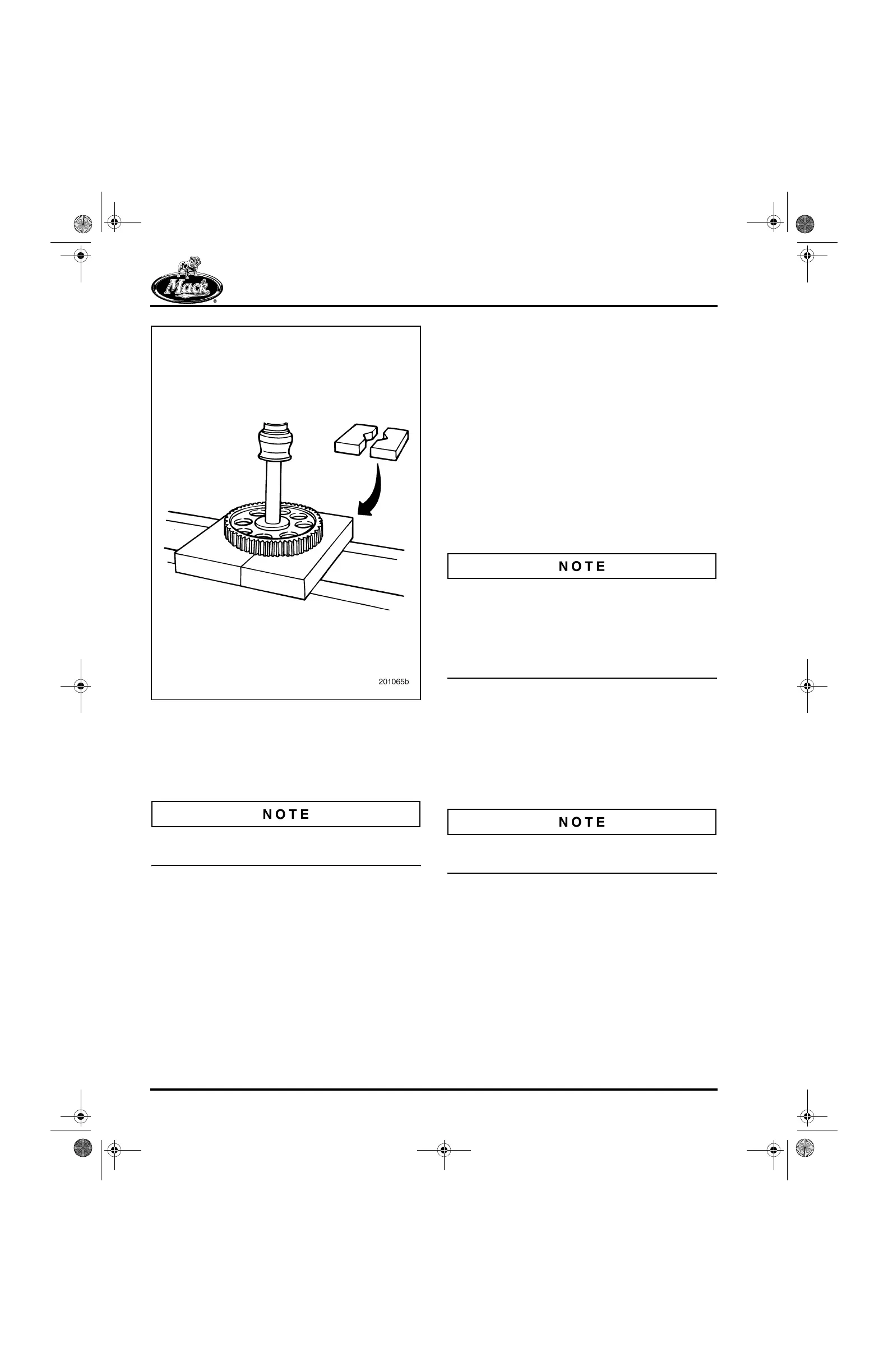

Figure 227 — Camshaft Gear Removal

INSPECTION

Refer to Figure 228.

1. Thoroughly clean the camshaft.

Use the magnaflux (PT7190) inspection

procedure to detect cracks.

2. Inspect the camshaft lobes and journals for

evidence of cracks, pitting, scoring or severe

wear. If any of these conditions exist,

replace the camshaft.

3. Inspect the camshaft gear and captured

thrust washer for cracks, pitting, scoring or

adverse wear.

4. Visually inspect the key for signs of

distortion or breakage.

CAMSHAFT GEAR INSTALLATION

The camshaft gear is shrink-fitted to the

camshaft. To install the gear, it must be heated in

an oven to 425°F (204°C). DO NOT attempt to

heat the gear with a welding torch as this method

will not provide even heating and could cause

weakening of the metal.

An oven is the preferred method for heating the

camshaft gear. However, an industrial grade hot

plate can be used as an alternative to the oven.

When using a hot plate, temperature sticks or a

thermocouple must be used to determine gear

temperature. The hot plate, temperature sticks

and thermocouple are available through any

industrial supply company.

The camshaft gear is a “long-life” part that should

be reused providing it is not damaged.

When installing the camshaft gear, use only the

heat method procedure below for both new or

used parts. DO NOT use a press to install the

gear.

HEAT METHOD — CAMSHAFT GEAR

INSTALLATION

Refer to Figure 228.

1. Using a suitable contact-type cleaner that

dries rapidly and leaves no residue,

thoroughly clean the camshaft and the gear.

The camshaft and gear must be grease- and

oil-free to ensure a good shrink-fit.

2. Install the key into the camshaft keyway. It

may be necessary to tap the key with a soft

metal hammer to ensure proper seating of

the key. The original key should be reused if

it not damaged. If the key is slightly loose in

the key slot, it may move when the cam gear

is being installed. To avoid this use a

hammer to make two or three small dings

along the top edges of the slot before

installing the key. When the key is installed,

the dings will help hold the key in place

when the gear is being installed.

5-111.bk Page 220 Monday, July 10, 2006 2:26 PM

Loading...

Loading...