Page 294

REPAIR INSTRUCTIONS, PART 1

2. Place the piston marked No. 1 on a clean,

flat surface. Rest the piston and rod

assembly on the piston crown with the rod

upward.

3. Apply a light coat of clean engine oil to the

piston and rings.

4. Apply a light coat of clean engine oil to the

inside surface of the piston ring compressor,

J 23442, PT7070-A, or equivalent.

5. Install the ring compressor by slipping it over

the rod and down over the piston skirt.

Continue to slide the tool downward,

carefully guiding the rings into the ring

grooves until the tool contacts the surface on

which the piston crown is resting.

6. Position the upper bearing insert into the

connecting rod. Align the tab in the bearing

insert with the notch in the rod. Be sure that

the hole in the bearing aligns with the oil

passage in the rod.

The hole in the upper connecting rod bearing

must be aligned with the oil passage in the

connecting rod. Otherwise, damage to the

bearing, rod and crankshaft journal will result.

7. Apply a light coat of clean engine oil to the

bearing surface.

8. Apply a light coat of clean engine oil to the

inside surface of the No. 1 cylinder sleeve.

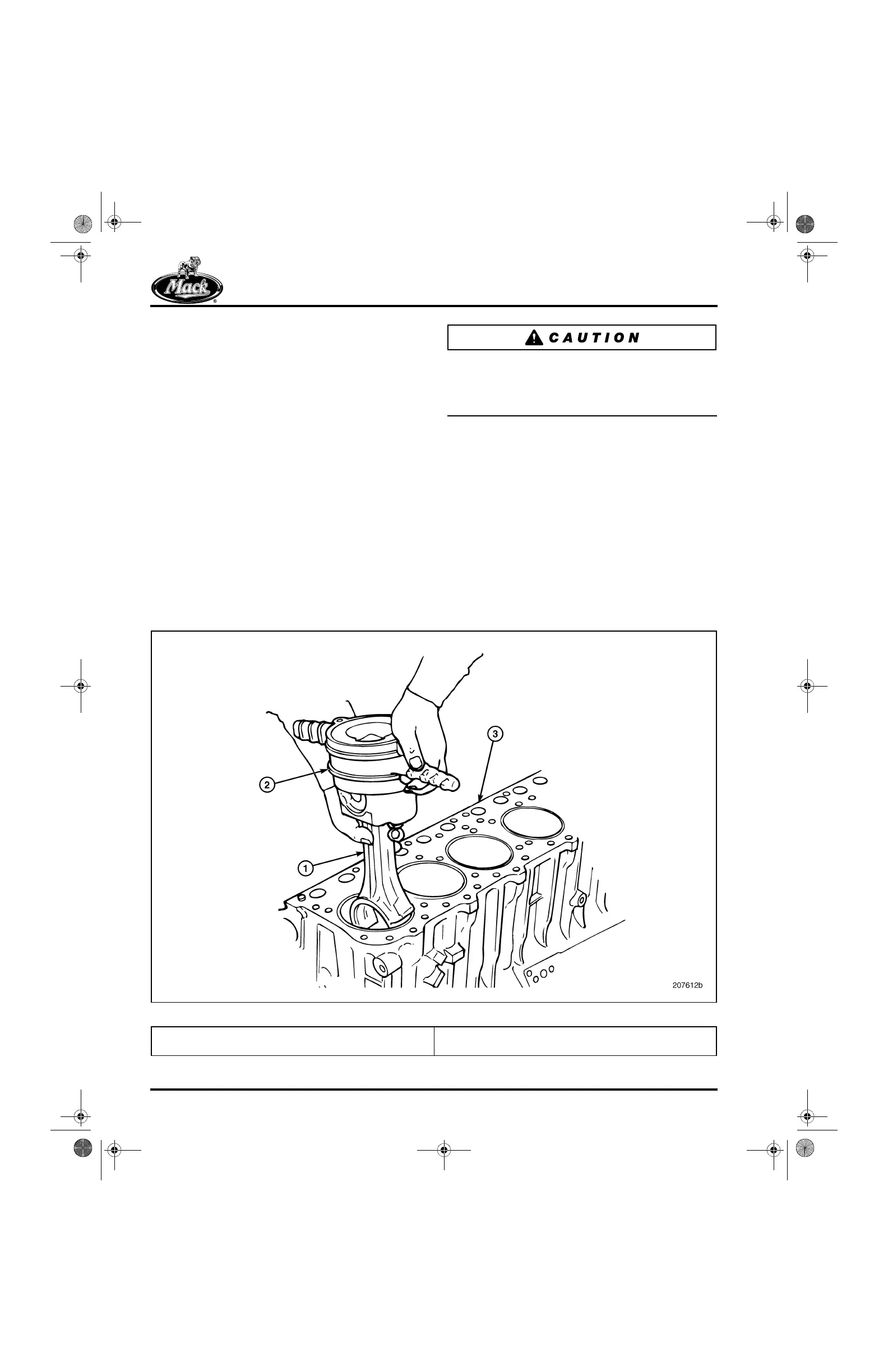

9. With the ring compressor in place, position

the piston and rod assembly into the No. 1

cylinder as shown in Figure 330 until the

compressor contacts the top of the sleeve.

The arrow and word FRONT on both the

piston crown and the connecting rod must

be facing the front of the engine.

330

Figure 330 — Piston and Connecting Rod Installation

1. Connecting Rod Assembly

2. Piston Ring Compressor Tool

3. Cylinder Block

5-111.bk Page 294 Monday, July 10, 2006 2:26 PM

Loading...

Loading...