REPAIR INSTRUCTIONS, PART 1

Page 329

4. Lubricate the threads and undersides of the

heads of the rocker arm capscrews with

clean engine oil. Place the capscrews in the

mounting brackets and tighten by hand as

much as possible.

Effective 4th quarter 2005, a revised rocker arm

shaft mounting bolt (part No. 416GC23M) was

implemented into production. These bolts are

available through the MACK Parts System, and

should be used as the replacement bolt anytime

the rocker arm shaft bolts are removed.

If any rocker arm shaft mounting bolts were found

to be broken at disassembly, all 12 mounting

bolts MUST be replaced.

5. Again, depress each rocker arm adjusting

screw so that the ball end is down and in full

contact with the push rod cup. As each

rocker arm is depressed, rotate the push rod

to ensure proper installation.

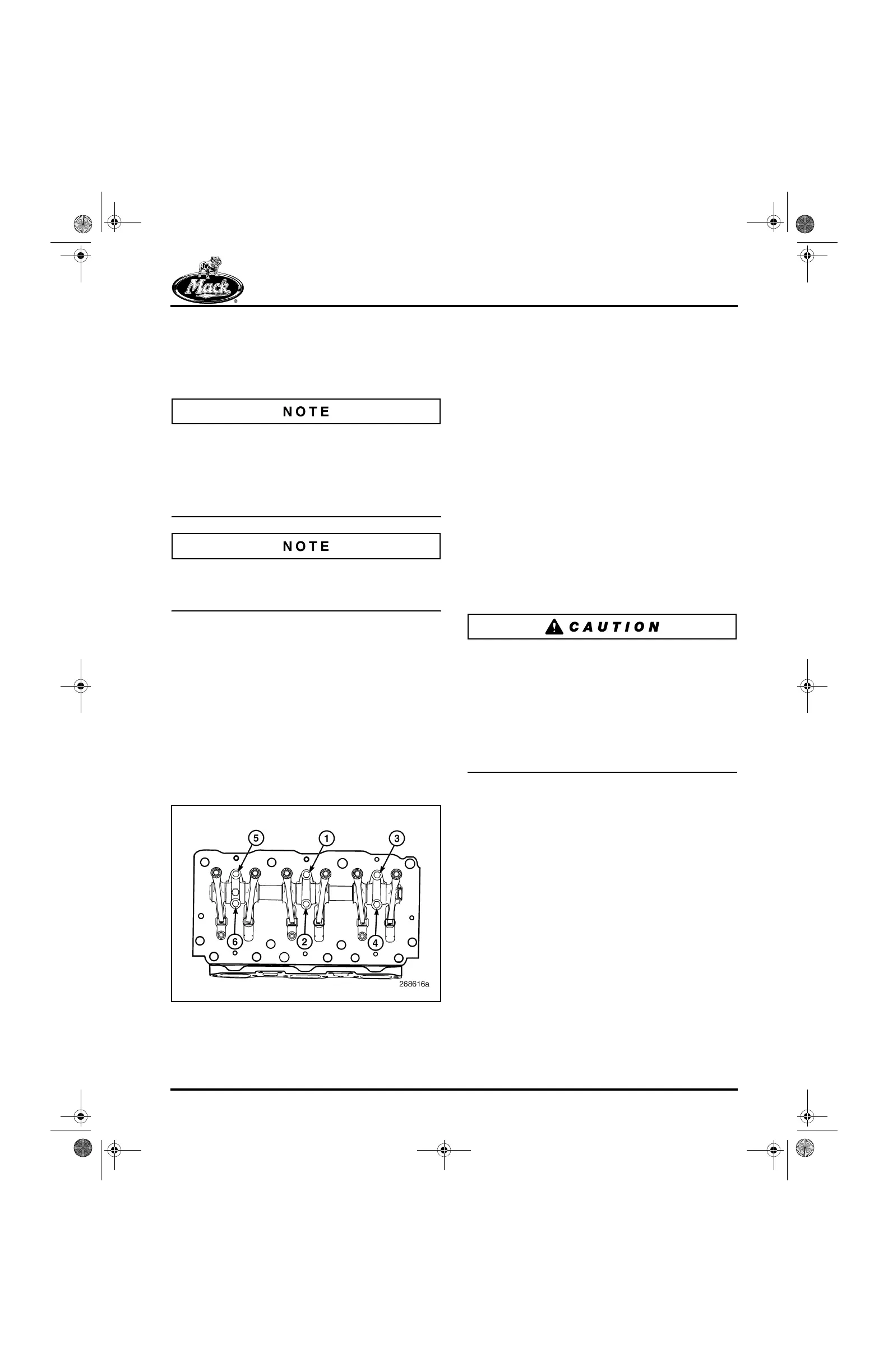

6. Beginning at the center mounting bracket

with capscrew No. 1, tighten the capscrews

in the sequence shown in Figure 385.

Tighten the capscrews to the specified

torque, 45 lb-ft (61 N폷m), using an accurately

calibrated torque wrench J 24407, or

equivalent.

385

Figure 385 — Rocker Shaft Assembly Capscrew

Tightening Sequence

7. Adjust the valve lash to the specified

settings. Refer to “Valve Yoke and Valve

Lash Adjustments” in the ENGINE SETUP

AND ADJUSTMENTS section.

INSTALLATION (J-TECH™ BRAKE-EQUIPPED

ENGINES)

Refer to Figure 387.

1. Make sure the oil supply screw is in position

on the rocker arm mounting bracket for each

cylinder head and tightened to specification,

5 lb-ft (6.8 N폷m).

2. Make sure that all 12 push rods are properly

seated in the respective lifter sockets with

standard push rods at the inlet valve

locations and spring-loaded at the exhaust

valve locations. Use care when checking the

push rod seating. DO NOT drop the push

rods onto the lifters.

Make sure the rocker adjusting screws are turned

completely upward into the rocker arms before

installing the rocker shaft or engine brake units on

the engine. If this is not done, tightening the

mounting bolts for the rocker shafts or engine

brake units, or rotating the engine to adjust the

valves, can bend the push rods or subject the

ceramic rollers to excessive loads which can

damage or break the rollers.

3. Place the rocker shaft assemblies in position

on the cylinder heads, making sure that the

mounting screw holes are properly aligned.

Depress the adjusting screw end of each

rocker arm so that the adjusting screw ball

end is down and in full contact with the push

rod cup. With the rocker arm depressed in

this fashion, rotate each push rod to be sure

it is properly seated in the lifter cup and at

the rocker arm adjusting screw.

5-111.bk Page 329 Monday, July 10, 2006 2:26 PM

Loading...

Loading...