Page 332

REPAIR INSTRUCTIONS, PART 1

INSTALLATION (MACK POWERLEASH™

BRAKE-EQUIPPED ENGINES)

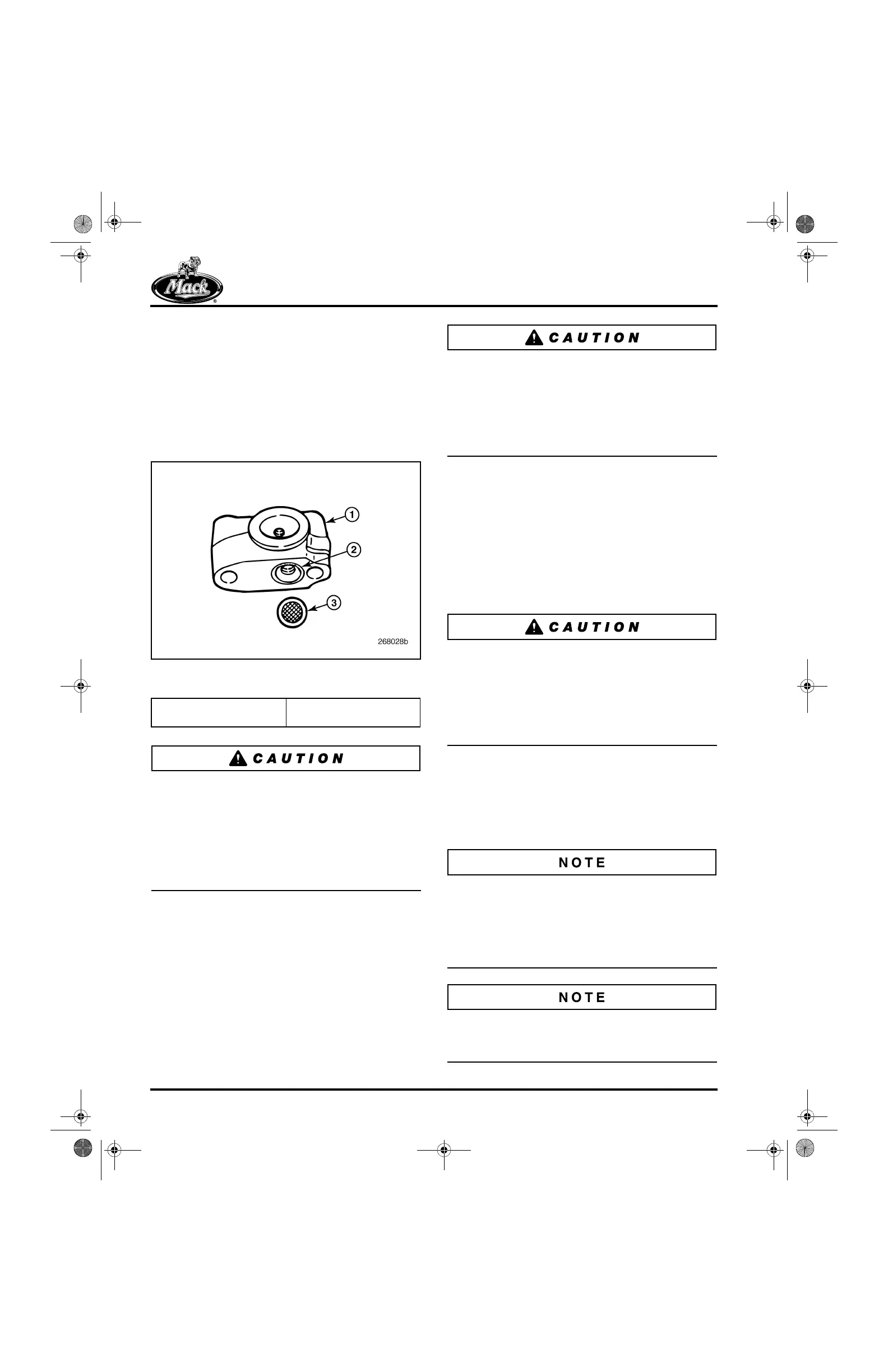

Before installing the PowerLeash™ rocker shaft,

verify that the oil supply screen is positioned in

the counterbore at the bottom of the front rocker

shaft mounting bracket. If the screen fits loosely

in the bore, use some grease to hold the screen

in place while the rocker shaft assembly is being

installed on the engine.

388

Figure 388 — Oil Supply Screen in Front Mounting

Bracket

If the screen should slip out of place during

installation of the rocker shaft assembly to the

engine, the screen edge may become pinched

between the rocker shaft mounting bracket and

the surface of the cylinder head. If this occurs,

broken hold-down bolts, a broken rocker shaft or

both can result with the possibility of major engine

damage.

1. Make sure all 12 push rods are properly

seated in the respective lifter sockets. When

installing push rods, use care to gently lower

them into position on the lifter cups. DO

NOT drop the push rods onto the lifters.

Make sure that all adjusting screws and brake

lash adjusting screws are screwed completely

upward into the rocker arms before installing the

rocker shaft on the engine. If this is not done,

tightening the mounting bolts for the rocker shafts

or rotating the engine to adjust the valves, can

bend the push rods.

2. Place the rocker shaft assemblies on the

cylinder heads and align the rocker bracket

mounting holes with the holes in the cylinder

head. Depress the adjusting screw end of

each rocker arm so that the adjusting screw

ball end is fully down into each push rod cup.

With the rocker arm depressed, rotate each

push rod to be sure it is fully seated in the

lifter cup and at the rocker arm adjusting

screw.

If the rocker shaft assembly is lifted off, or

partially lifted off the cylinder head at anytime

during the installation procedures, steps 1 and 2

above must be repeated. Not having the rockers

positioned as described in step 2 above, or lifting

the rockers are the usual causes of dislodging a

push rod from the lifter cup.

3. Lubricate the threads of the rocker shaft

mounting bracket bolts and the undersides

of the bolt heads with clean engine oil. Place

the bolts into the mounting brackets, then

start each bolt by hand and tighten by hand

as much as possible.

Effective 4th quarter 2005, a revised rocker arm

shaft mounting bolt (part No. 416GC23M) was

implemented into production. These bolts are

available through the MACK Parts System, and

should be used as the replacement bolt anytime

the rocker arm shaft bolts are removed.

If any rocker arm shaft mounting bolts were found

to be broken at disassembly, all 12 mounting

bolts MUST be replaced.

1. Front Mounting Bracket

2. Oil Supply Port

3. Oil Supply Screen

5-111.bk Page 332 Monday, July 10, 2006 2:26 PM

Loading...

Loading...