Page 346

REPAIR INSTRUCTIONS, PART 1

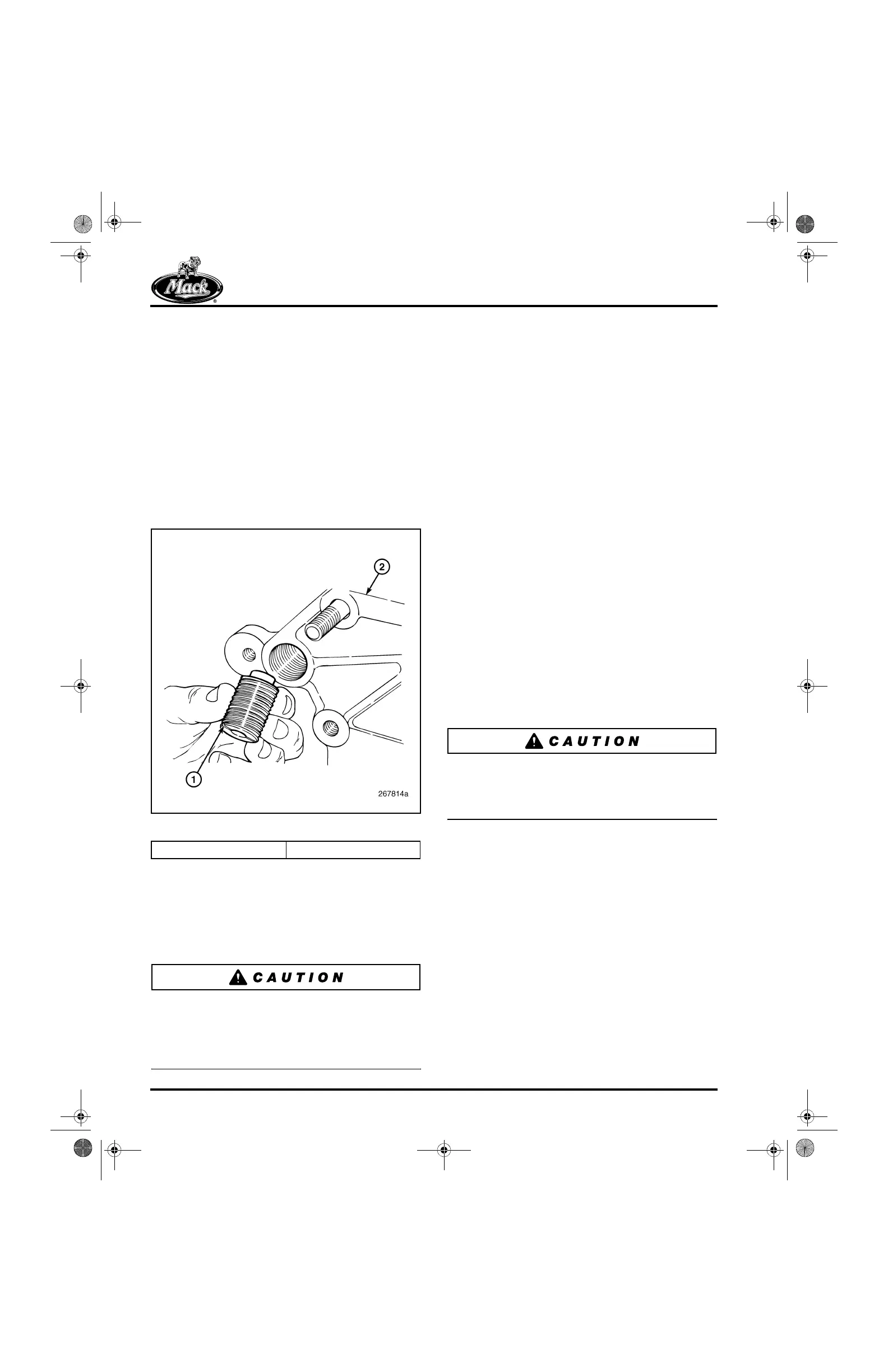

1. With the water pump housing positioned on

a bench with the cylinder block/head

mounting surface facing up, place a new

O-ring in the groove at the coolant inlet

flange. Use MACK Code 442 grease or any

quality O-ring grease to hold the O-rings in

place for assembly.

2. Stand the housing on edge and from the

front, start the threaded inserts into the

mounting bores at the top of the housing

(Figure 407). Turn them in until the collar of

each protrudes from the back side and the

shoulder is 0.020-inch (0.5 mm) under to

flush with the back side.

407

Figure 407 — Threaded Insert Installation

3. Again, with the housing standing on edge

and from the front, insert two mounting

capscrews and washers into the

mid-position bolt holes. The two mid-position

holes are slightly smaller to serve as pilot

holes for installation.

The water pump cartridge assembly and water

pump housing mounting bolts should not be

lubricated before installation. Instead, apply

thread sealing compound to all cartridge

assembly and housing capscrews.

4. Place the housing in position at the front of

the cylinder block and start the mid-position

capscrews into the block, far enough to

secure the housing from falling. The housing

should be free to move slightly back for

installation of the engine lifting bracket in the

following steps.

5. Place the engine lifting bracket in position

(bend angle facing forward) between the

housing and cylinder head (Figure 406).

Make sure the bracket mounting holes clear

and slip into position on the insert collars.

6. Push the housing against the block and

hand-tighten the mid-position mounting

capscrews.

7. Install the two mounting capscrews and

washers in the low-position mounting holes,

hand-tight.

8. Make sure the lifting bracket mounting holes

are properly positioned on the insert collars

and then tighten the mid-position and

low-position capscrews to specification,

69 lb-ft (94 N폷m), in sequence A, B, C, D

shown in Figure 406.

9. Using a suitable slotted socket, tighten the

two threaded inserts to specification, 50 lb-in

(5.6 N폷m).

Insert is to be tightened to 51 lb-in (5.6 N

폷

m). Use

care not to overtighten the threaded inserts.

Doing so could place undue stress on the

housing, causing it to bow and eventually break.

10. Install the remaining two mounting

capscrews (no washers) through the

threaded inserts and tighten to specification,

40 lb-ft (55 N폷m).

1. Threaded Insert 2. Pump Housing

5-111.bk Page 346 Monday, July 10, 2006 2:26 PM

Loading...

Loading...