DESCRIPTION AND OPERATION

Page 33

FRONT FAN AND ACCESSORY DRIVE

ARRANGEMENT

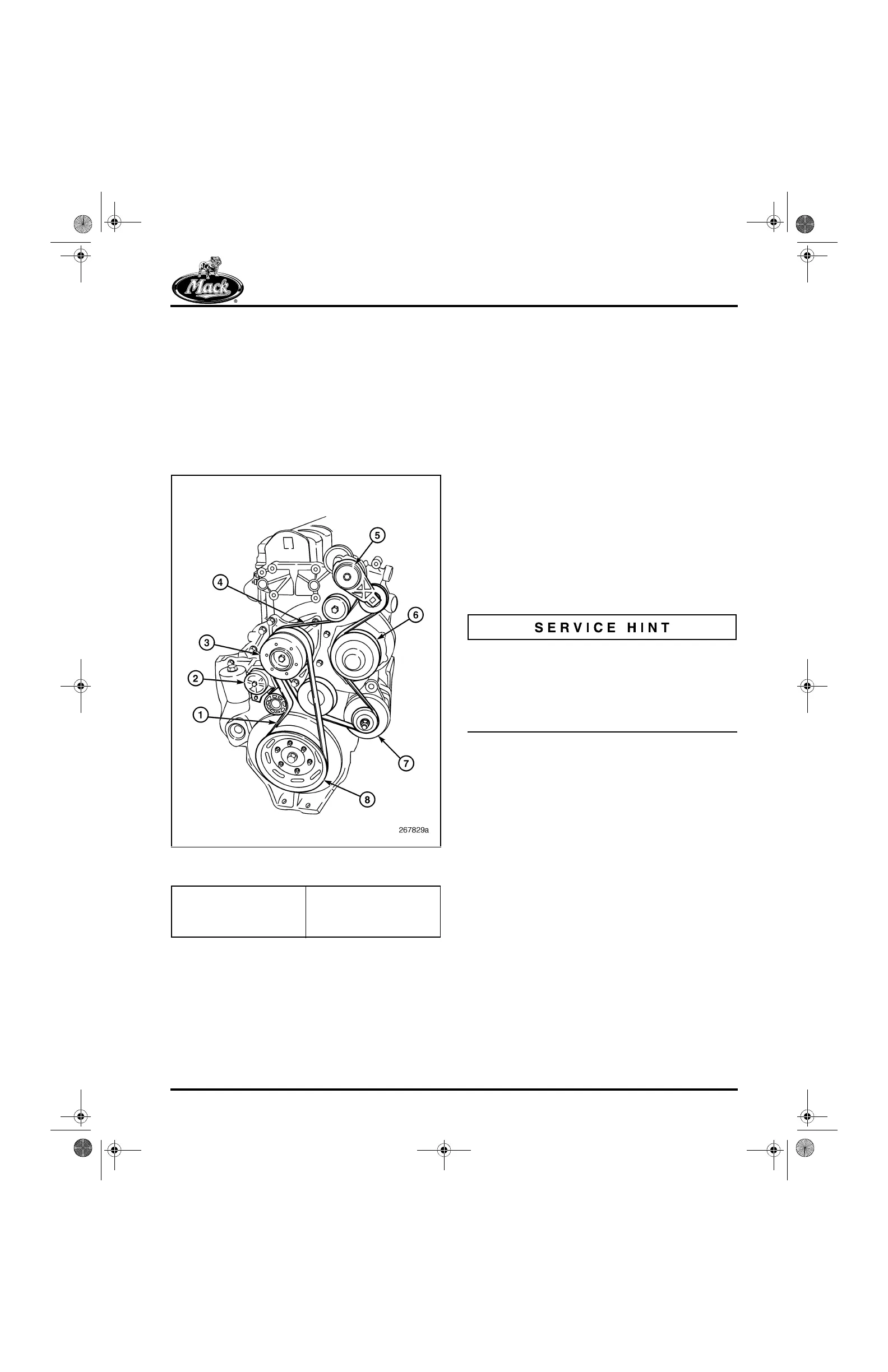

In the dual poly-V drive belt arrangement, the fan

drive is driven directly from the crankshaft pulley

by a 10-rib poly-V belt. In turn, the water pump,

alternator and the air conditioning compressor (if

equipped) are driven off the fan-drive hub by a

6-rib poly-V belt (Figure 26). Two tensioners are

used, one for the fan drive and one for the

accessory drive.

26

Figure 26 — Dual Poly-V Drive Belt Arrangement

(Typical Non-AC Application)

Both manually tensioned and automatically

tensioned systems are used. Whether an engine

has the manually tensioned or automatically

tensioned system depends on the specific engine

configuration and application. Service and

adjustment is the same as current engines.

Specific accessory drive belt routing per chassis

is included in the “SCHEMATIC & ROUTING

DIAGRAMS” section of this manual.

VALVE SPRINGS, ROTATORS AND PUSH

RODS

While valve design is unchanged, valve springs

are of a new design. The progressive rate design

is made from an improved material capable of

working under the higher engine speeds. The AC

engine is produced with a single-spring

configuration at the inlet locations and a

dual-spring configuration at the exhaust locations

(Figure 27). The addition of an inner spring at the

exhaust locations assists in seating the valves

under the higher exhaust manifold

back-pressures. The dual-spring configuration

also requires a change in the design of the valve

rotator, the exhaust valve guide and the valve

stem seal.

Current-production exhaust location inner springs

are now being painted white. These springs are

completely interchangeable with the former bare

steel springs. The white paint was added to help

verify that the inner spring is present after the

cylinder head is built-up.

Valve Rotators

The dual-spring exhaust configuration changes

the design of the valve rotator to include seating

surfaces for both the inner and outer valve

springs. This two stepped rotator is shown in

Figure 29.

Early design configurations for both the single

inlet and dual exhaust spring placed the rotators

on the “tip-end” of the valve spring with a

hardened washer at the valve spring seat. The

hardened washers were added to prevent

damage to the cylinder head that could be

caused by the valve spring. Beginning June

2003, the valve spring configuration changed to a

bottom rotator design, however, the single inlet

and dual exhaust spring configuration remained.

The bottom rotator design eliminated the need for

the hardened washer spring seats. With both top

and bottom designs, the rotator used with the

dual springs is different from the rotator used with

the single spring and the correct rotator must be

used.

1. 10-Rib Poly-V Belt

2. Tensioner

3. Fan-Drive Hub

4. 6-Rib Poly-V Belt

5. Tensioner

6. Water Pump

7. Alternator

8. Crankshaft Pulley

5-111.bk Page 33 Monday, July 10, 2006 2:26 PM

Loading...

Loading...