REPAIR INSTRUCTIONS, PART 3

Page 447

547

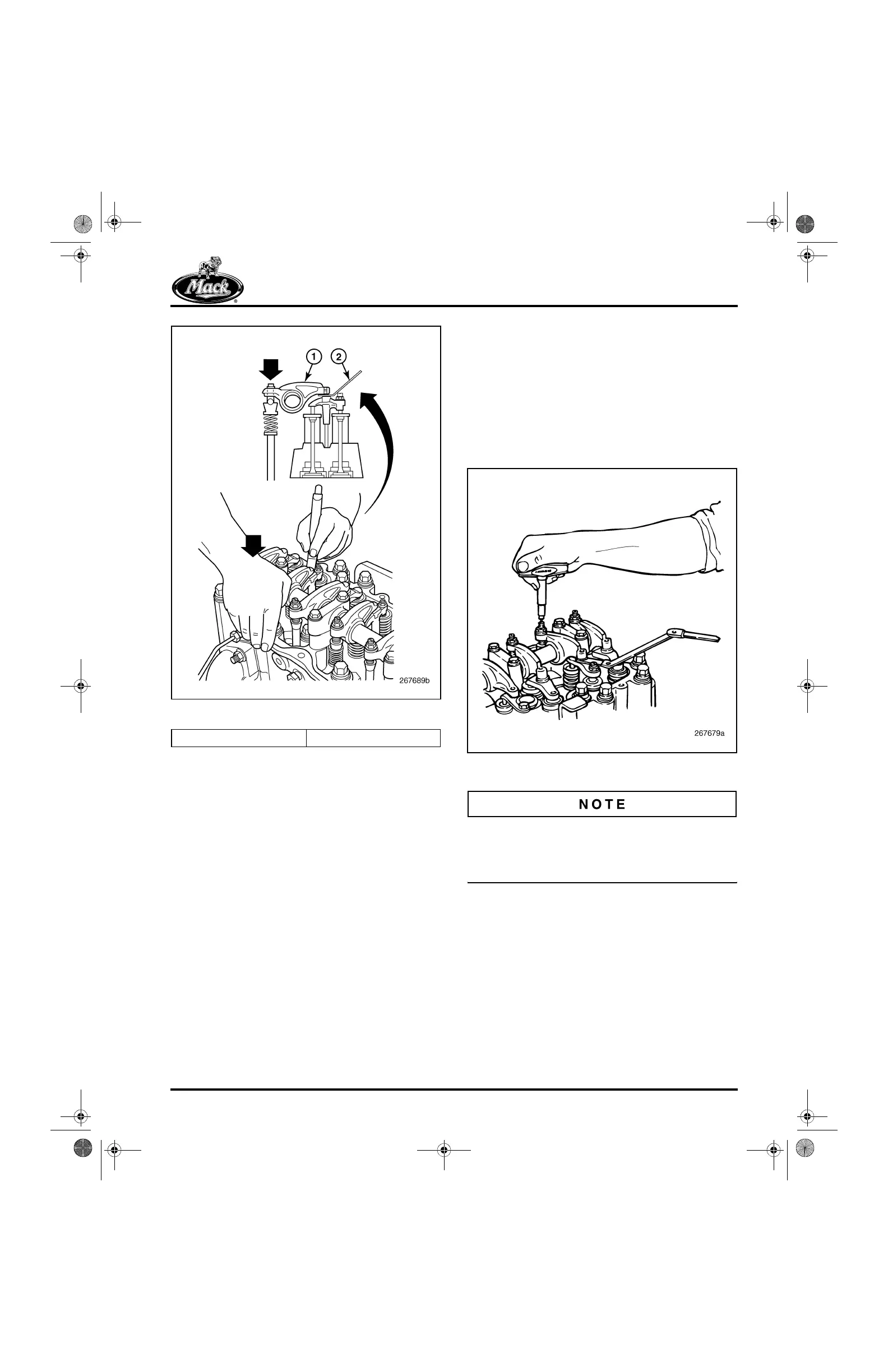

Figure 547 — Inserting Thickness Gauge

3. Using the torque screwdriver, J 29919 or

equivalent, slowly turn the rocker arm

adjusting screw clockwise. At the exhaust

locations, the push rod spring will compress

as the adjusting screw is being tightened. At

the inlet locations, the extra clearance will be

“taken-up” as the adjusting screw is being

tightened.

4. Continue tightening the adjusting screw until

the torque screwdriver clicks. At the exhaust

locations, the push rod spring seats are now

in contact and the push rod is solid and the

valve lash is now properly set. Do not tighten

the adjusting screw any further. At the inlet

locations, when the torque screwdriver

clicks, all excessive lash has been

“taken-up” and inlet lash is now set to the

thickness of the feeler gauge.

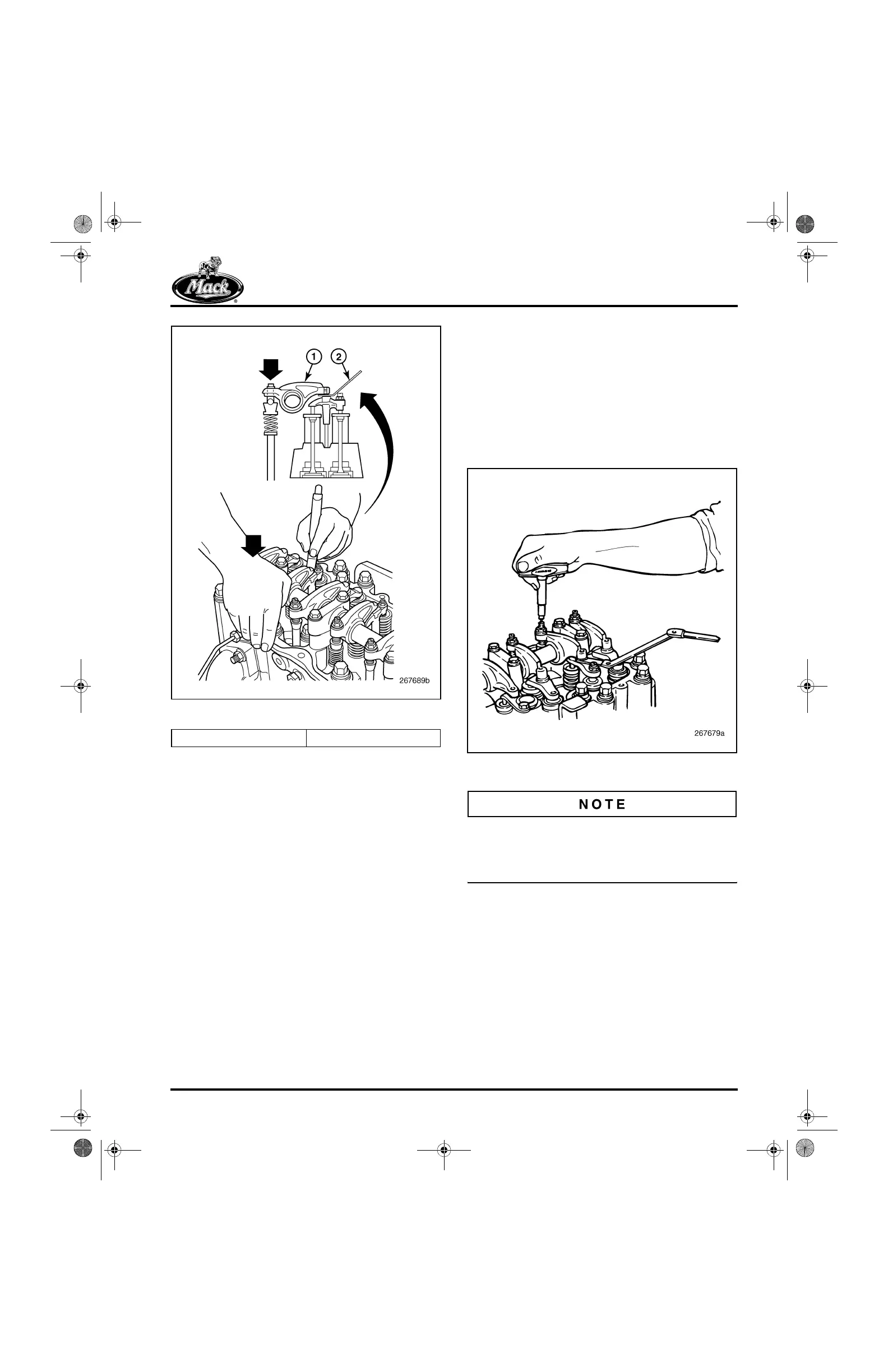

548

Figure 548 — Adjusting Exhaust Valve Lash

The torque screwdriver may allow the valve

adjusting screw to loosen slightly when it clicks at

the pre-set torque. Always recheck valve lash

adjustment as described in step 7.

5. Remove the torque screwdriver and hold the

adjusting screw in position with a standard 5

mm Allen wrench to keep it from turning.

Tighten the flange-head jam nut to

specification, 45 lb-ft (61 N폷m).

1. Rocker Arm 2. Feeler Gauge

5-111.bk Page 447 Monday, July 10, 2006 2:26 PM

Loading...

Loading...