Page 446

REPAIR INSTRUCTIONS, PART 3

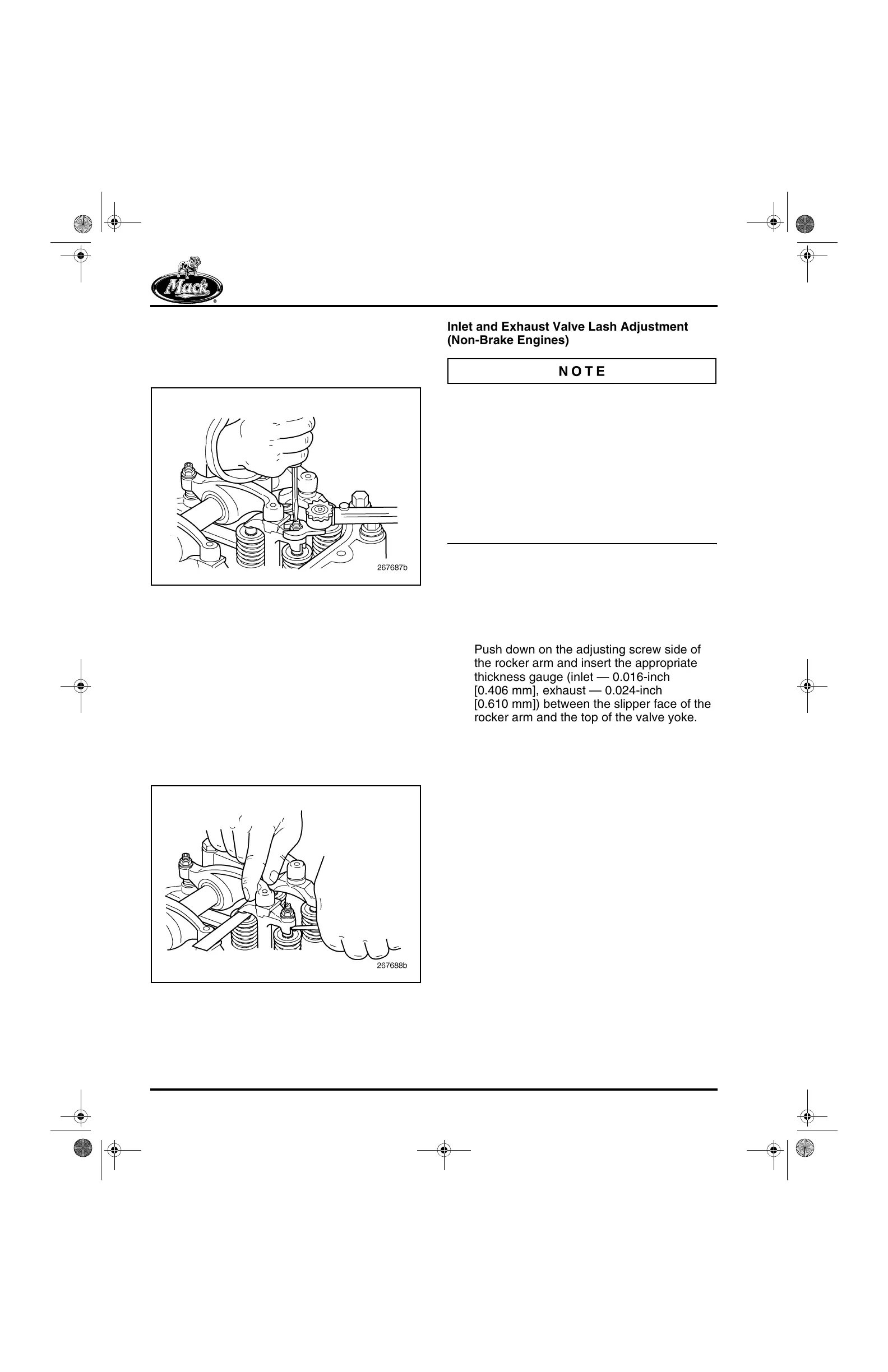

6. Hold the valve yoke adjusting screw in this

position and tighten the adjusting screw jam

nut to the specified torque, 33 lb-ft (45 N폷m),

using torque wrench J 24407, or equivalent.

545

Figure 545 — Yoke Adjusting Screw and Jam Nut

(Slotted Screw Shown)

7. Check the valve yoke adjustment as follows:

a. Insert 0.010-inch (0.25 mm) thickness

gauges between the inboard and

outboard valve stem tips and the valve

yoke.

b. Exert moderate force on the yoke by

pressing on the rocker arm slipper end.

An equal “drag” should be felt on both

thickness gauges. If drag is not equal,

readjust the valve yoke.

546

Figure 546 — Checking Yoke Adjustment

Inlet and Exhaust Valve Lash Adjustment

(Non-Brake Engines)

The following procedure was developed for

adjusting exhaust valve lash on engines

equipped with spring-loaded push rods. This

same procedure, however, can be used for

adjusting inlet valve lash, even though the inlet

valves use standard push rods. If the torque

screwdriver is not available, an alternate

procedure that does not require the torque

screwdriver is outlined in the “Inlet and Exhaust

Valve Lash Adjustment for Non-Brake Engines

(Alternate Procedure)” section that follows.

1. Loosen the rocker arm nut and back out the

adjusting screws at the No. 1 cylinder a

couple of turns and thread the new

flange-head jam nuts on the adjusting

screws, leaving them loose so that

adjustments can be made.

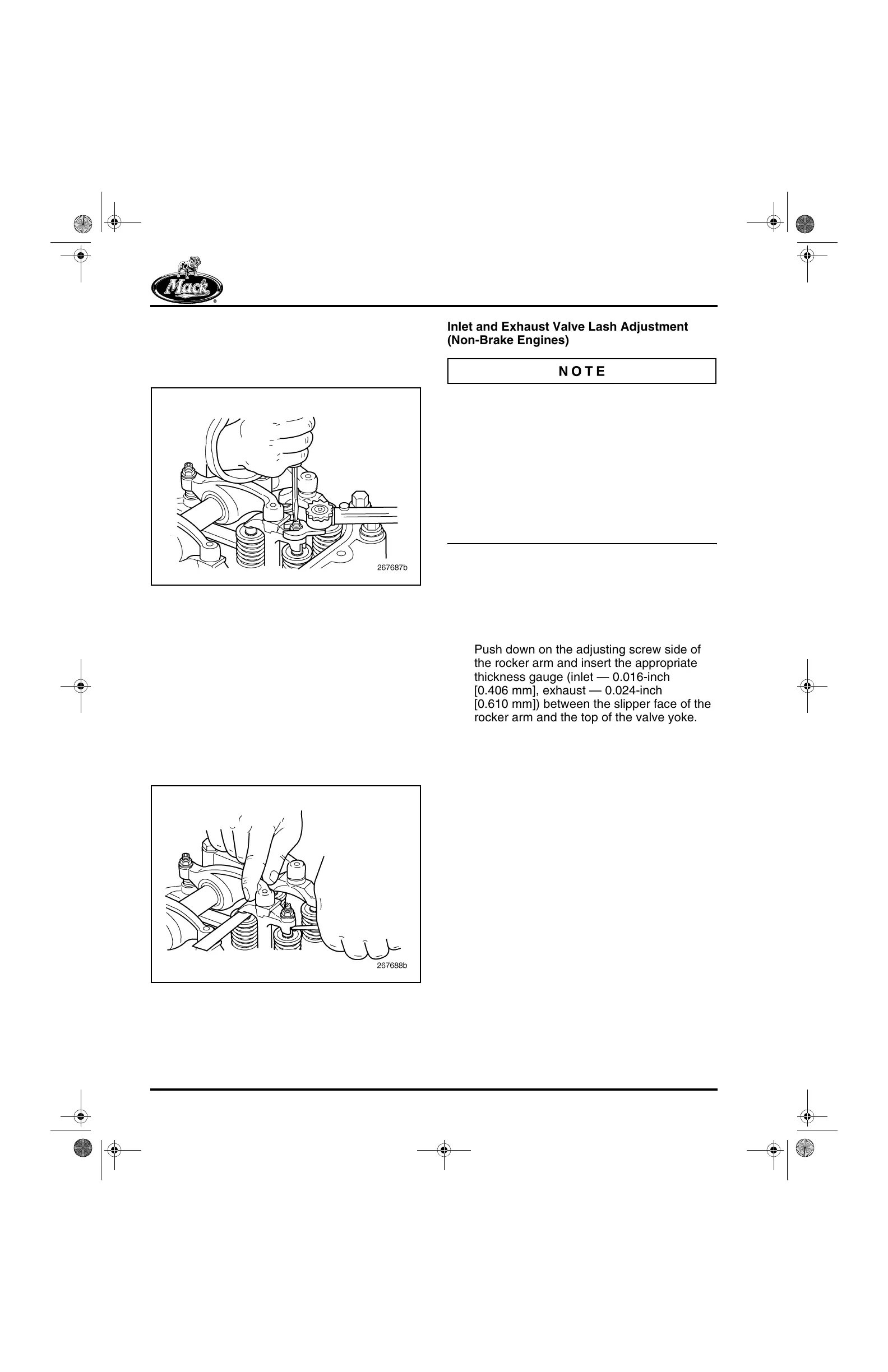

2. Push down on the adjusting screw side of

the rocker arm and insert the appropriate

thickness gauge (inlet — 0.016-inch

[0.406 mm], exhaust — 0.024-inch

[0.610 mm]) between the slipper face of the

rocker arm and the top of the valve yoke.

Leave the thickness gauge in place.

5-111.bk Page 446 Monday, July 10, 2006 2:26 PM

Loading...

Loading...