REPAIR INSTRUCTIONS, PART 3

Page 449

Inlet and Exhaust Valve Lash Adjustment for

Non-Brake Engines (Alternate Procedure)

If an oz-in or lb-in torque screwdriver or torque

wrench is not available, valve lash can be

adjusted (for both brake and non-brake engines)

in the same manner as described above (by

installing the appropriate thickness gauge and

tightening the adjusting screw), but using careful

hand-pressure to compress the push rod spring

instead of the 6 lb-in torque screwdriver.

Use a 5 mm internal hex wrench in place of the

torque screwdriver to turn the adjusting screw.

Turn the screw clockwise until a large increase in

resistance is felt, indicating that the push rod is

fully compressed and the internal stops of the

push rod upper and lower spring seats are bottom

against each other. No further tightening force is

to be applied to the adjusting screw, or an

inaccurate valve adjustment may result. At that

point, valve lash should be properly set and the

adjusting screw jam nut can be tightened to

45 lb-ft (61 N폷m).

Always recheck the adjustment by exerting

downward pressure by hand on the adjusting

screw and on the rocker arm to fully compress

the push rod while rechecking with the thickness

gauge. When holding the push rod compressed

for the lash overcheck, normal thickness gauge

drag will result. However, after the valve lash is

set, and downward pressure on the rocker arm is

released, the push rod spring pressure will put

increased drag on the thickness gauge.

Continuation of Adjustments for Remaining

Cylinders

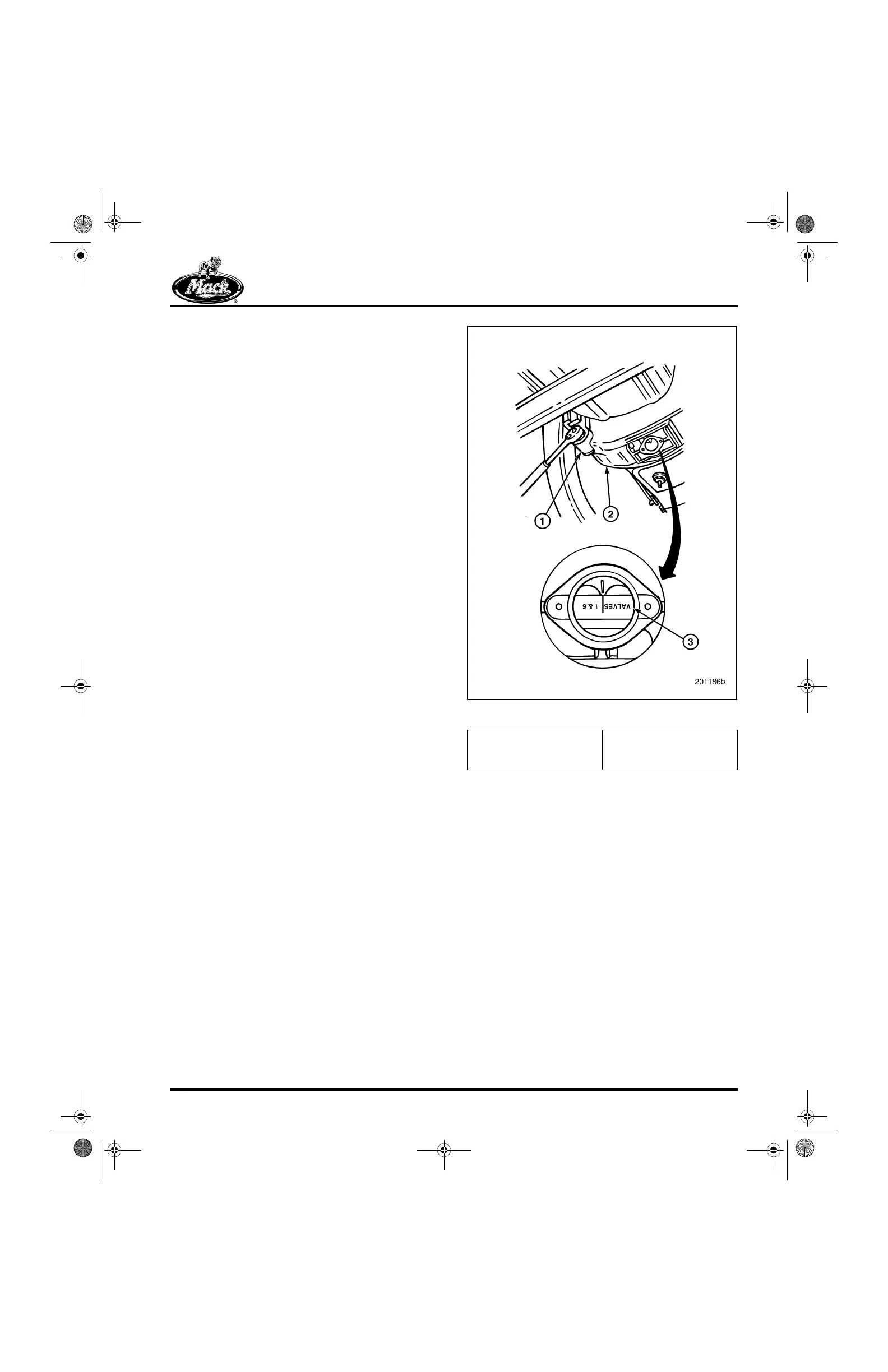

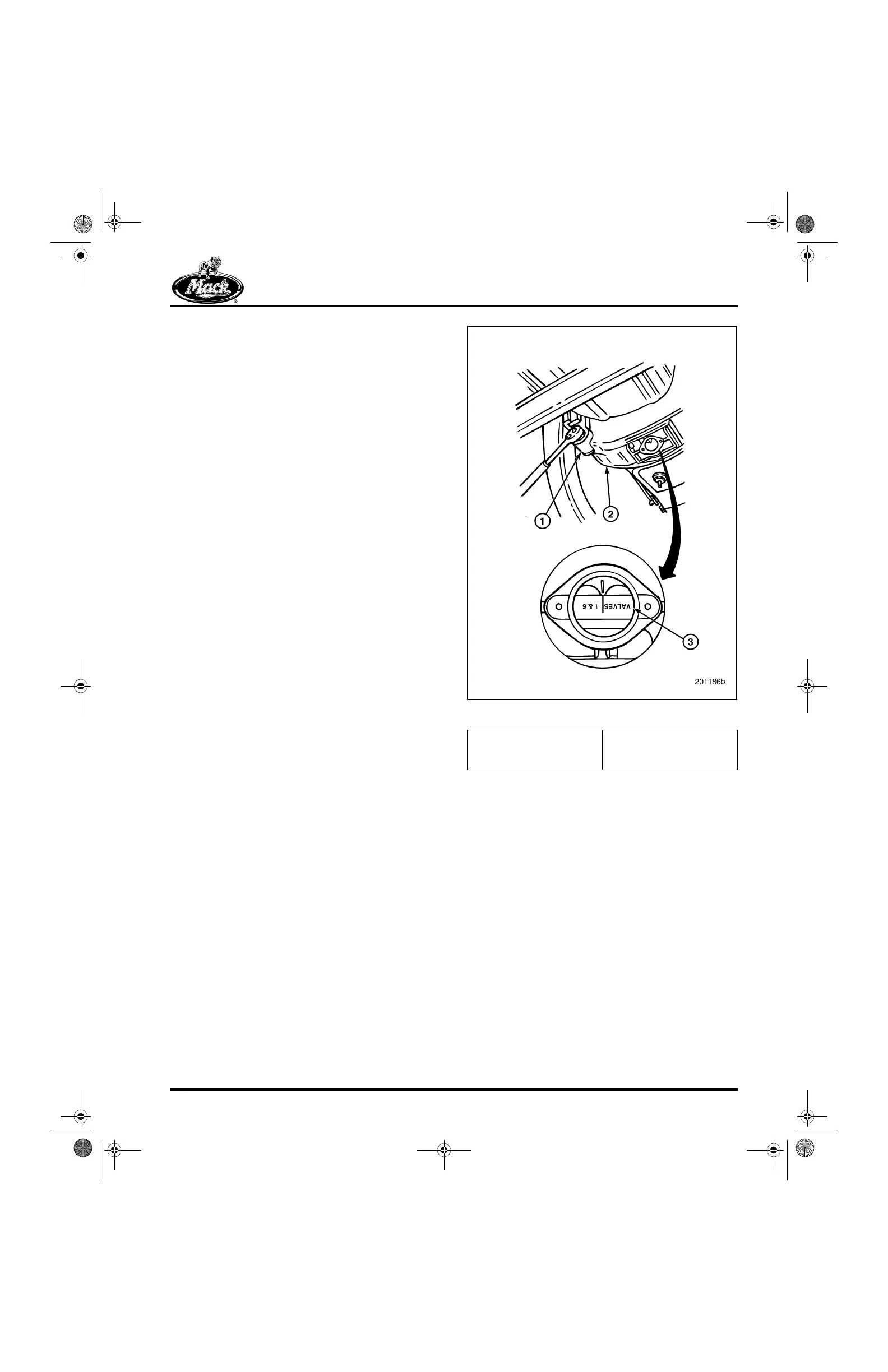

1. Using a barring socket, manually rotate the

engine crankshaft (Figure 551) in normal

rotation direction 120 degrees until the

center of the timing pointer hole in the

flywheel housing aligns with the “2 and 5”

mark on the flywheel and the No. 5 piston is

on the compression stroke.

551

Figure 551 — Valve Adjustment Markings on Flywheel

2. Adjust the final intake and exhaust valve

lash for cylinder No. 5 as described for

cylinder No. 1. Continue this procedure for

each of the remaining cylinders, following

the engine firing order sequence,

1-5-3-6-2-4.

1. Barring Socket

J 38587-A

2. Flywheel Housing

3. Flywheel

5-111.bk Page 449 Monday, July 10, 2006 2:26 PM

Loading...

Loading...