REPAIR INSTRUCTIONS, PART 3

Page 451

4. Exert moderate force on the valve yoke by

pressing on the rocker arm slipper end. Turn

the yoke adjusting screw clockwise until it

makes solid contact with the outboard valve

stem tip (a light drag should be felt on the

adjusting screw).

Engines equipped with a J-Tech™ engine brake

will have an actuator pin adjusting screw in the

exhaust yoke.

Do not allow anything to press down on the

actuating pin during adjustment. The pin must be

fully extended, approximately 1/4 inch

(6.350 mm) above the top of the hollow adjusting

screw. If the pin is held down and not fully

extended, an improper adjustment and engine

failure will result.

554

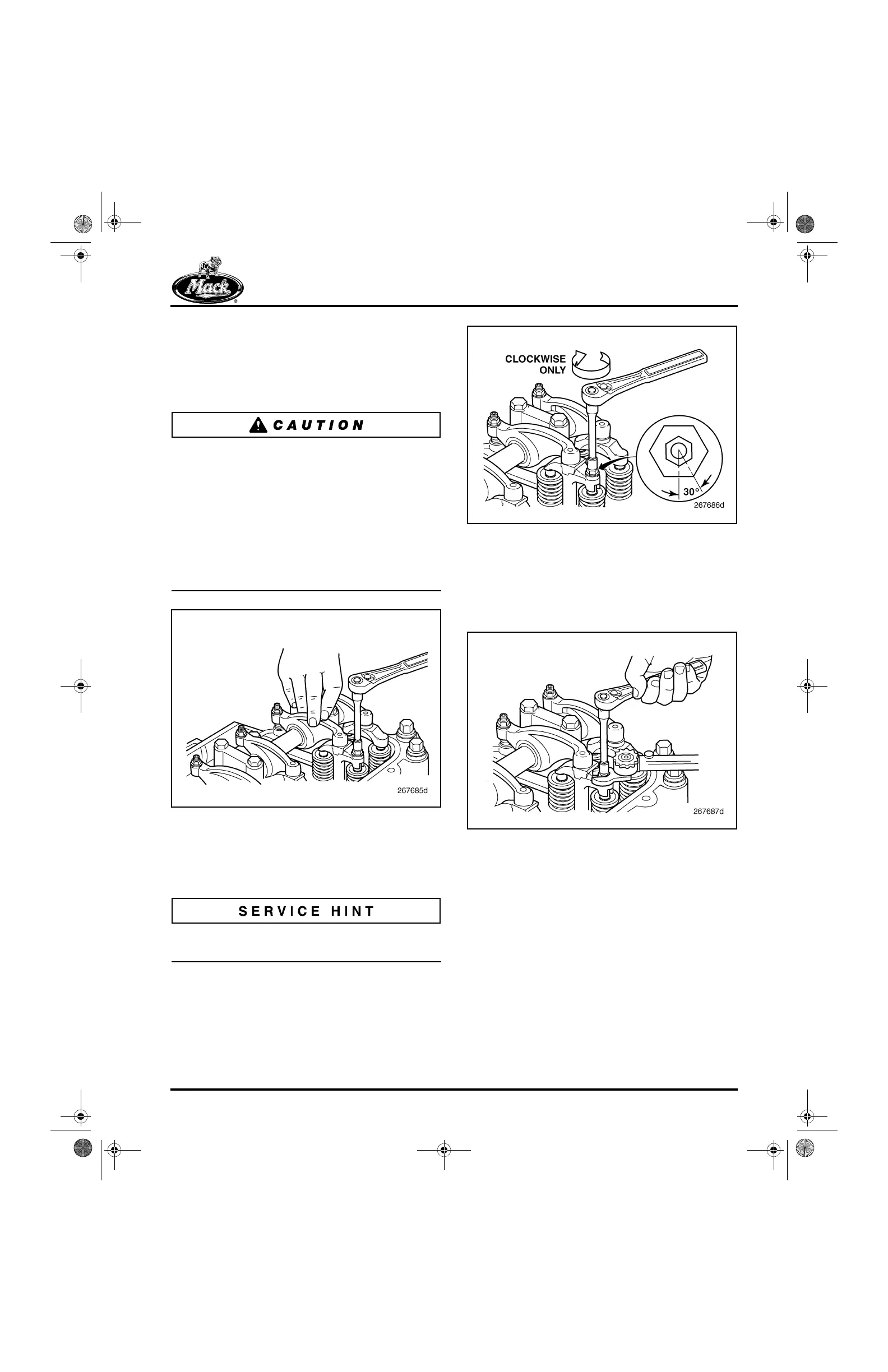

Figure 554 — Turning Yoke Adjusting Screw Until It

Contacts Valve Stem

5. After the adjusting screw makes solid

contact with the valve stem, turn the screw

clockwise an additional 30 degrees.

A 30-degree turn is equal to 1/2 of a flat on the

adjusting screw jam nut.

555

Figure 555 — Turning Adjusting Screw an Additional

30-Degree Turn

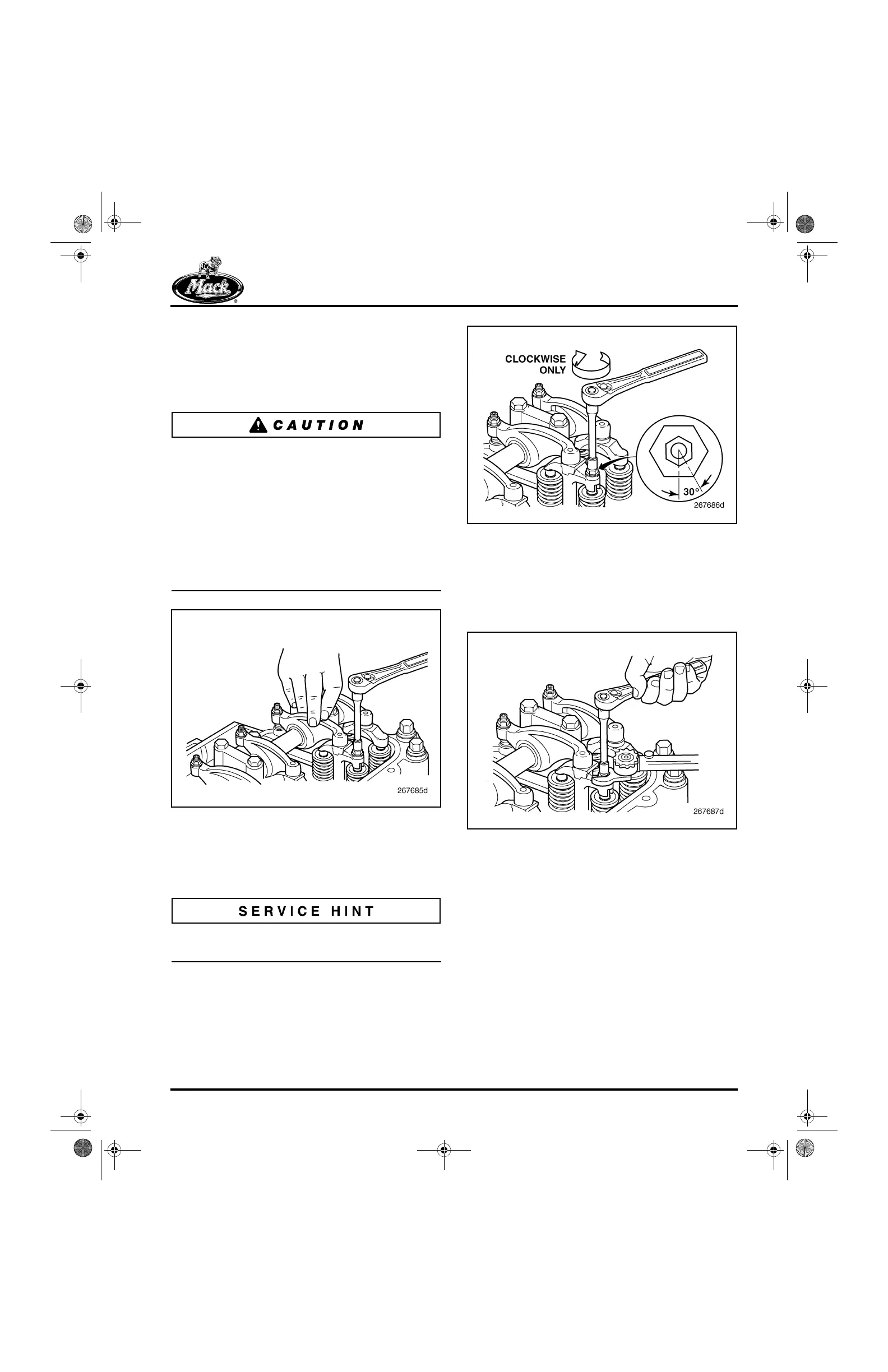

6. Hold the valve yoke adjusting screw in this

position and tighten the adjusting screw jam

nut to the specified torque, 33 lb-ft (45 N폷m),

using torque wrench J 24407, or equivalent.

556

Figure 556 — Yoke Adjusting Screw and Jam Nut

7. Check the valve yoke adjustment as follows:

a. Insert 0.010-inch (0.25 mm) thickness

gauges between the inboard and

outboard valve stem tips and the valve

yoke.

b. Exert moderate force on the yoke by

pressing on the rocker arm slipper end.

An equal “drag” should be felt on both

thickness gauges. If drag is not equal,

readjust the valve yoke.

5-111.bk Page 451 Monday, July 10, 2006 2:26 PM

Loading...

Loading...