DESCRIPTION AND OPERATION

Page 35

29

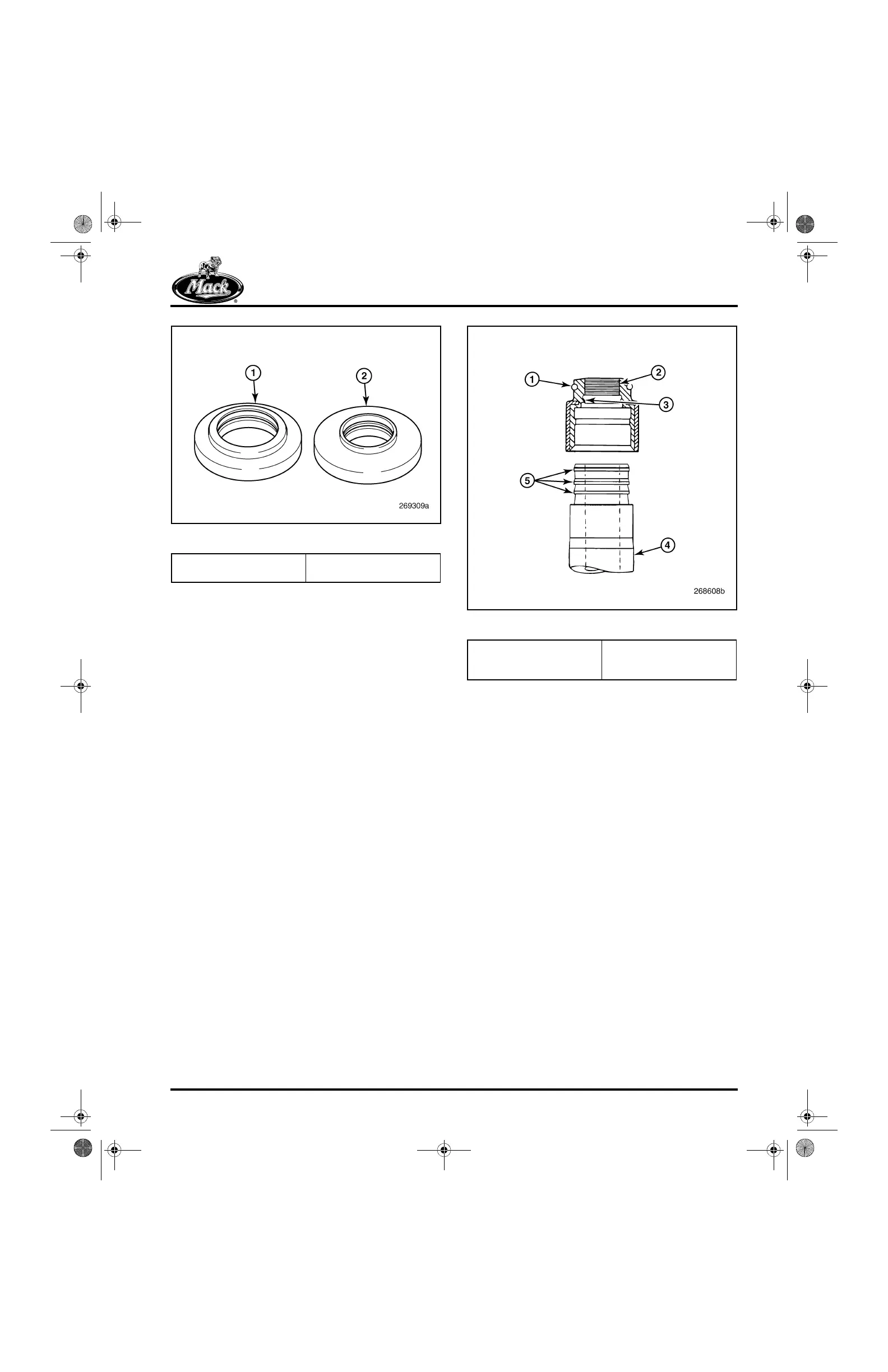

Figure 29 — Bottom Rotators

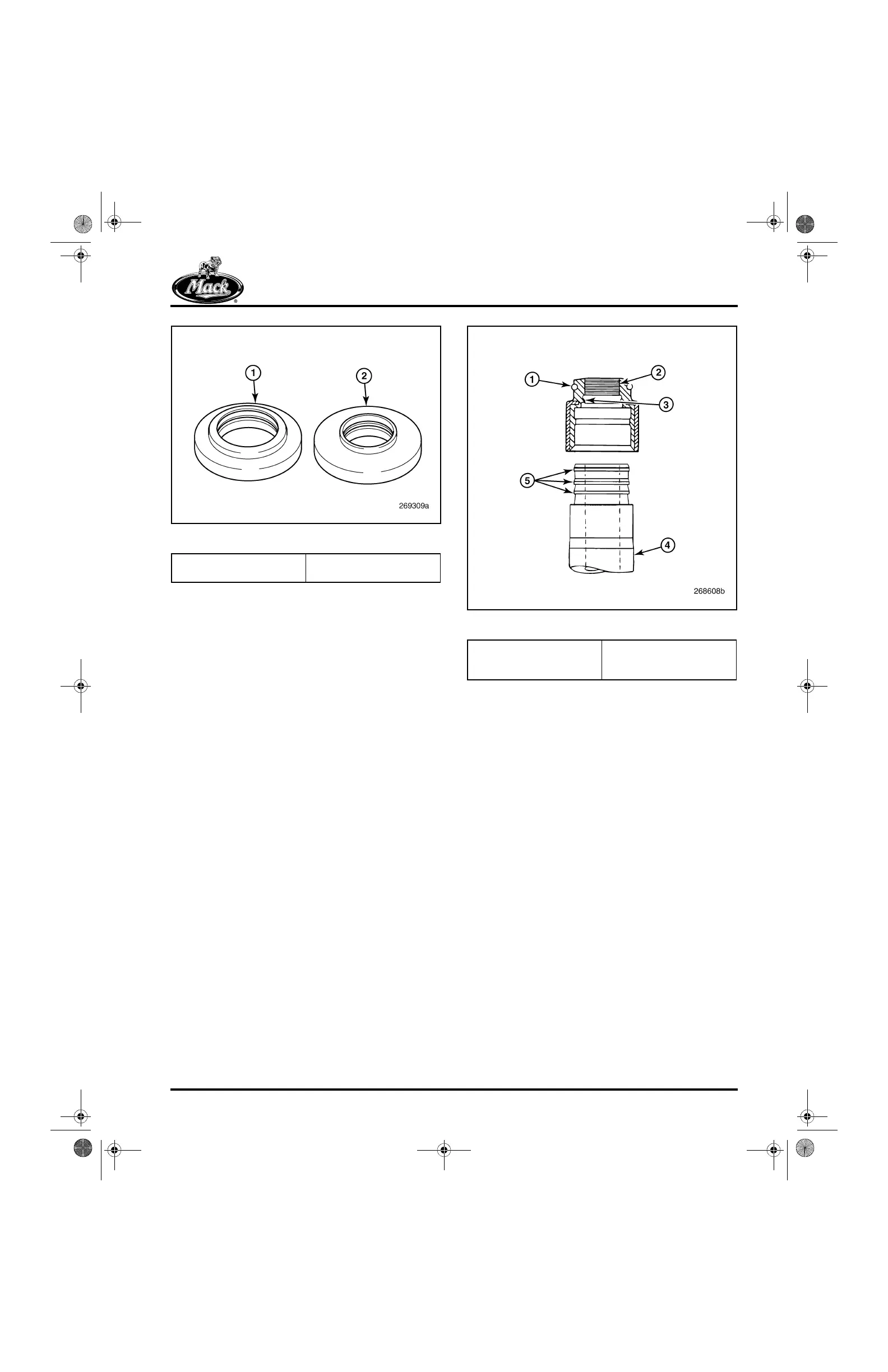

Valve Stem Seals

The seal introduced with ASET™ engines is

smaller than the previously used seal. This seal

requires a new valve guide that is approximately

1/8 inch (6.35 mm) smaller than the previous

guide and seal to allow clearance for the inner

valve spring used on the exhaust locations. For

standardization purposes, the new valve guide

and seal are used at inlet locations as well.

30

Figure 30 — Valve Stem Seal (Later Design)

Spring-Loaded Push Rods

All ASET™ engines are equipped with

spring-loaded push rods at the exhaust locations,

the same as those phased into production on the

E-Tech™ engine. These push rod assemblies

have a spring at the rocker arm end, and are

designed to keep the roller lifter in constant

contact with the cam. Additionally, this push rod

design reduces valve clatter that results from the

engine brake camshaft exhaust lobe clearances

and operating dynamics of the exhaust valve

train. The spring-loaded push rods are currently

used at the exhaust valve locations only.

1. Rotator for Dual Springs

(Exhaust Location)

2. Rotator for Single Valve

Spring (Inlet Location)

1. Steel Retainer Band

2. Multi-Lip Section

3. Blowback Lip

4. Valve Guide

5. Three Sharp Ridges

5-111.bk Page 35 Monday, July 10, 2006 2:26 PM

Loading...

Loading...