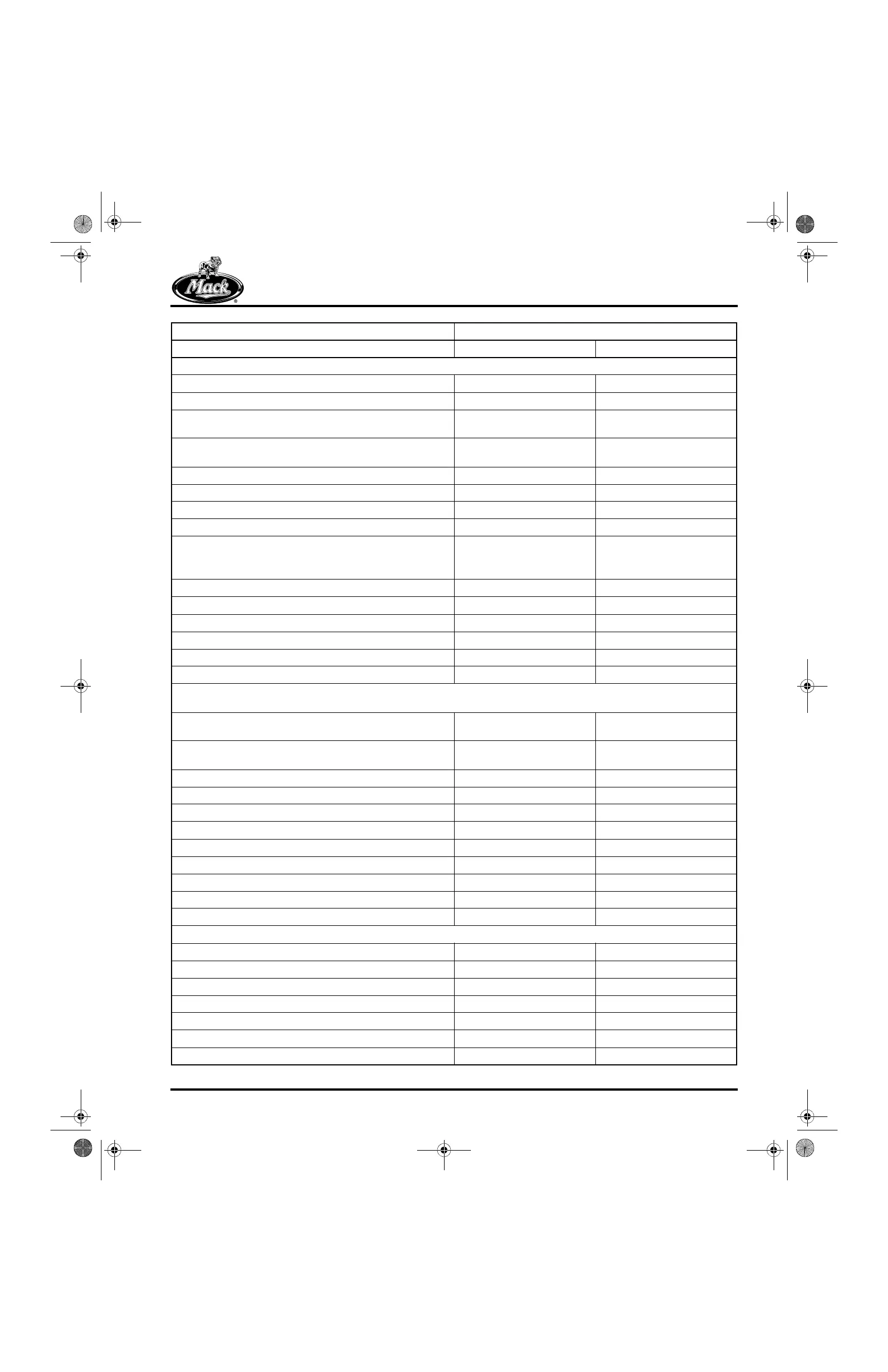

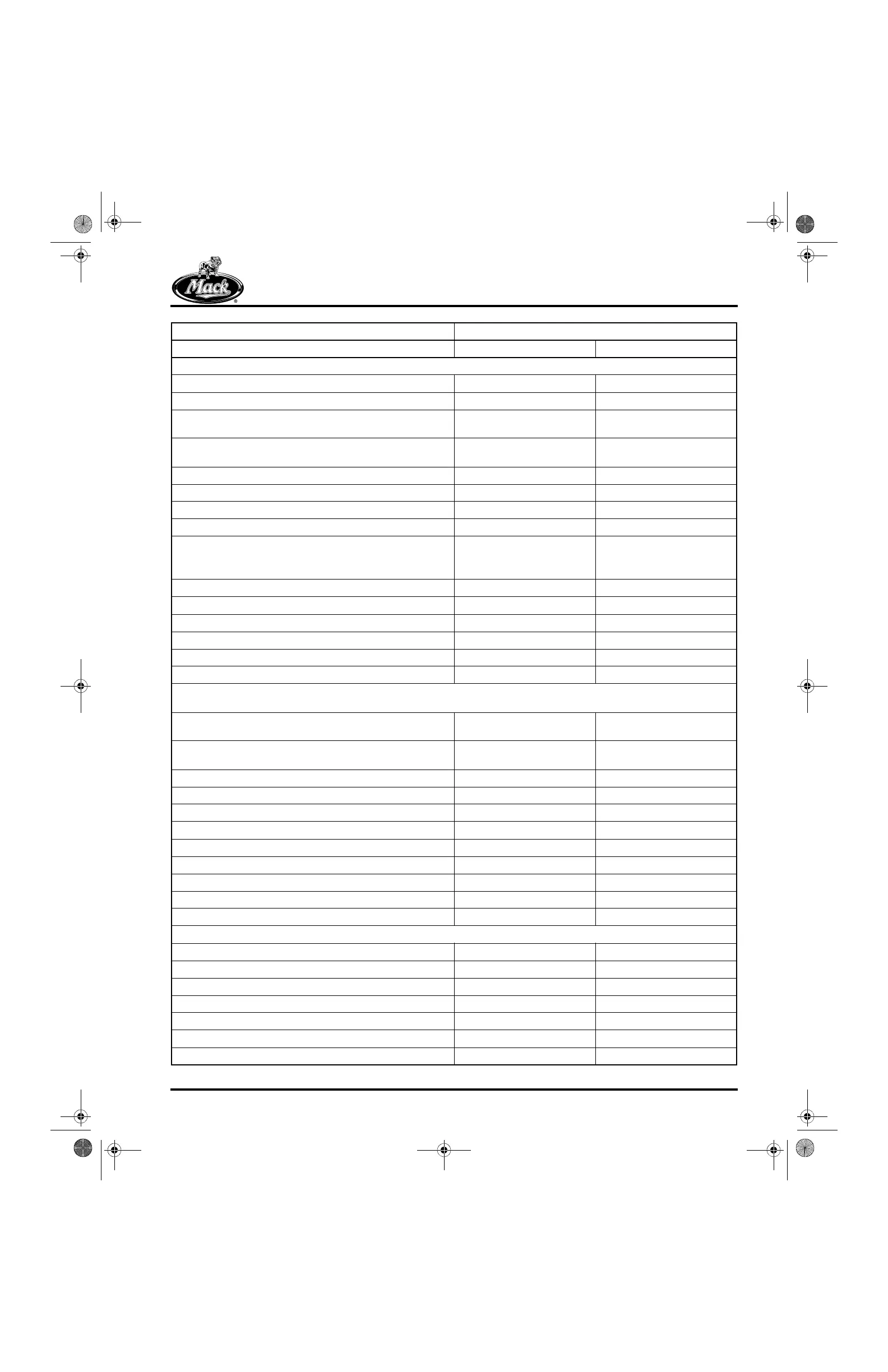

SPECIFICATIONS

Page 473

CYLINDER BLOCK

Deck Flatness (across one cylinder head) 0.002 in. 0.0508 mm

Deck Flatness (across both cylinder heads) 0.004 in. 0.1016 mm

Dowel Pin Holes (flywheel housing-to-block mounting, left

side)

0.6237–0.6247 in. 15.8420–15.8674 mm

Dowel Pin Holes (flywheel housing-to-block mounting, right

side)

0.6807–0.6817 in. 17.2898–17.3152 mm

Dowel Pin Holes (front cover-to-block mounting, left side) 0.5557–0.5567 in. 14.1148–14.1402 mm

Dowel Pin Holes (front cover-to-block mounting, right side) 0.4987–0.4997 in. 12.6670–12.6924 mm

Cylinder Bore in Block (upper) 5.501–5.500 in. 139.725–139.970 mm

Cylinder Bore in Block (lower) 5.1266–5.1250 in. 130.2156–130.1750 mm

Cylinder Bore Out-of-Round or Taper (on diameter)

(During manufacturing, the cylinder bores are honed with a

torque-plate [simulated cylinder head] installed.)

0.004 in. max., without torque

plate installed

0.1016 mm

Sleeve OD (at upper pilot diameter) 5.5040–5.5030 in. 139.8016–139.7762 mm

Sleeve Bead for Fire Ring (protrusion above sleeve channel) 0.0067–0.010 in. 0.1702–0.2540 mm

Sleeve in Bore (upper press-fit) 0.004–0.002 in. 0.1016–0.0508 mm

Sleeve in Bore (lower loose fit) 0.0029–0.0003 in. 0.0737–0.0076 mm

Main Bearing Bore in Block 4.818–4.817 in. 122.3772–122.3518 mm

Main Bearing ID (in place) 4.502–4.4996 in. 104.3508–114.2898 mm

Note: Extension of the cylinder sleeve above the cylinder block deck can vary under the same head, as long as all are within

the 0.024–0.029 inch (0.610–0.737 mm) specification for ASET™ AC engines.

Cyl. Sleeve Flange Channel-to-Block Deck (DO NOT

measure from top of bead.)

0.024–0.029 in. 0.610–0.737 mm

Cyl. Sleeve ID (installed, See “NOTE 8 — CYLINDER

SLEEVE ID” on page 489.)

4.876–4.877 in. 123.850–123.876 mm

EUP Tappet Bore 1.7334 + 0.0012/−0.0004 in. 44.028 + 0.0305/−0.0102 mm

EUP Tappet OD 1.7299–1.7307 in. 43.939–43.960 mm

EUP Tappet-to-Bore Clearance 0.0023–0.0047 in. 0.058–0.119 mm

Valve Roller Follower Bore 1.1245–1.1255 in. 28.562–28.588 mm

Valve Roller Follower OD 1.122–1.123 in. 28.499–28.524 mm

Valve Roller Follower-to-Bore Clearance 0.0015–0.0035 in. 0.038–0.089 mm

Valve Roller Follower H-Ring Bore 1.1245–1.1255 in. 28.562–28.588 mm

Valve Roller Follower H-Ring OD 1.1261–1.1265 in. 28.603–28.613 mm

Valve Roller Follower H-Ring-to-Bore Press Fit 0.0006–0.0020 in. 0.015–0.051 mm

CYLINDER HEAD

Alignment Across Exhaust Ports 0.005 in. 0.127 mm

Deck Flatness (over 18 in./45.72 cm) 0.0015 in. 0.0381 mm

Overall Height 6.391–6.397 in. 162.331–162.484 mm

Fire Ring Groove (width) 0.030–0.036 in. 0.762–0.914 mm

Fire Ring Groove (depth) 0.005–0.013 in. 0.127–0.330 mm

Fire Ring Groove ID 5.137–5.139 in. 130.479–130.531 mm

Valve Guide OD 0.6886–0.6881 in. 17.4904–17.4777 mm

Tolerances Are Shown Low to High Standard Size or Fit

Component English Metric

5-111.bk Page 473 Monday, July 10, 2006 2:26 PM

Loading...

Loading...