Page 50

DESCRIPTION AND OPERATION

49

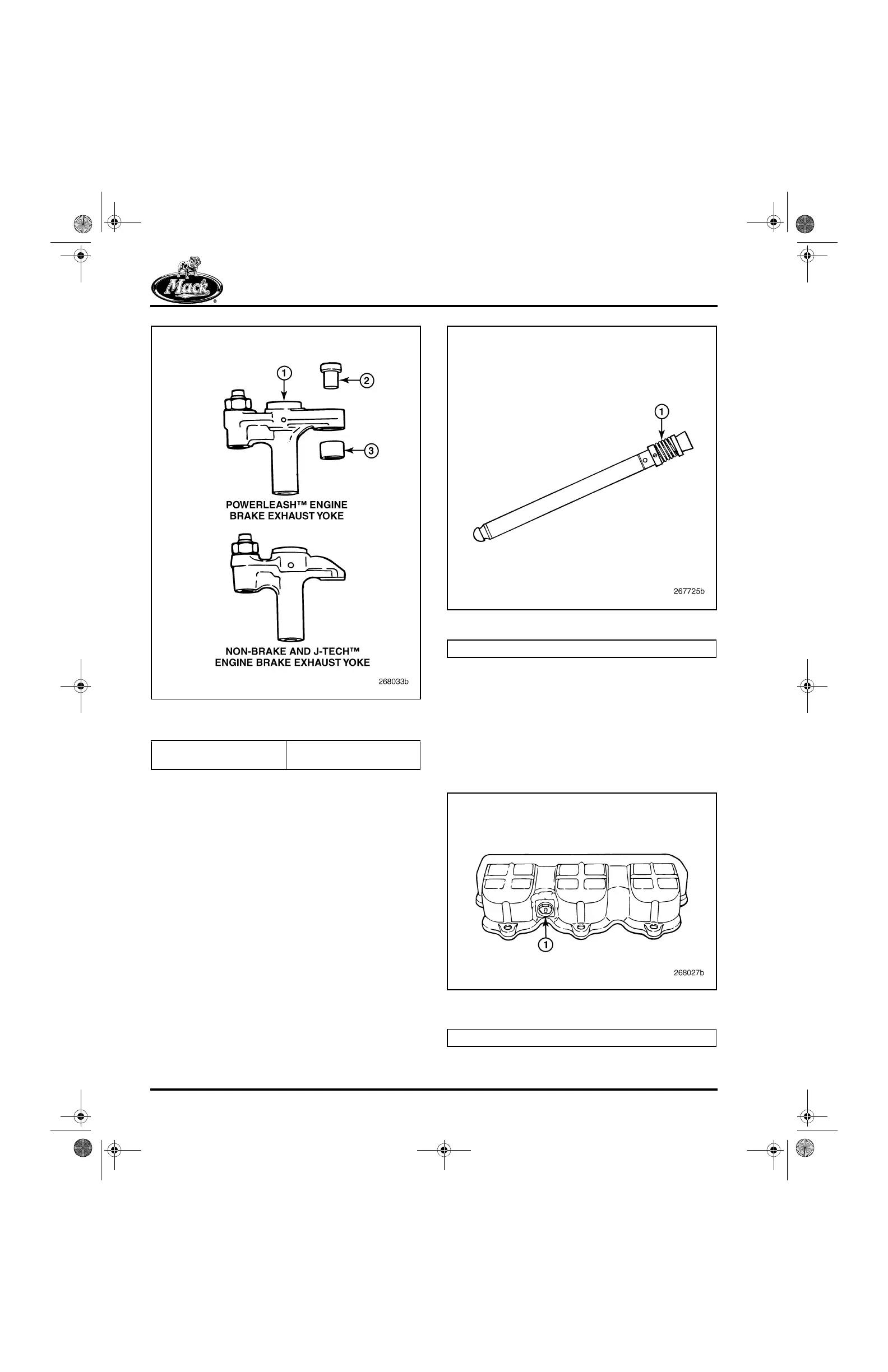

Figure 49 — Exhaust Yoke, Actuating Pin and Valve

Stem Cap

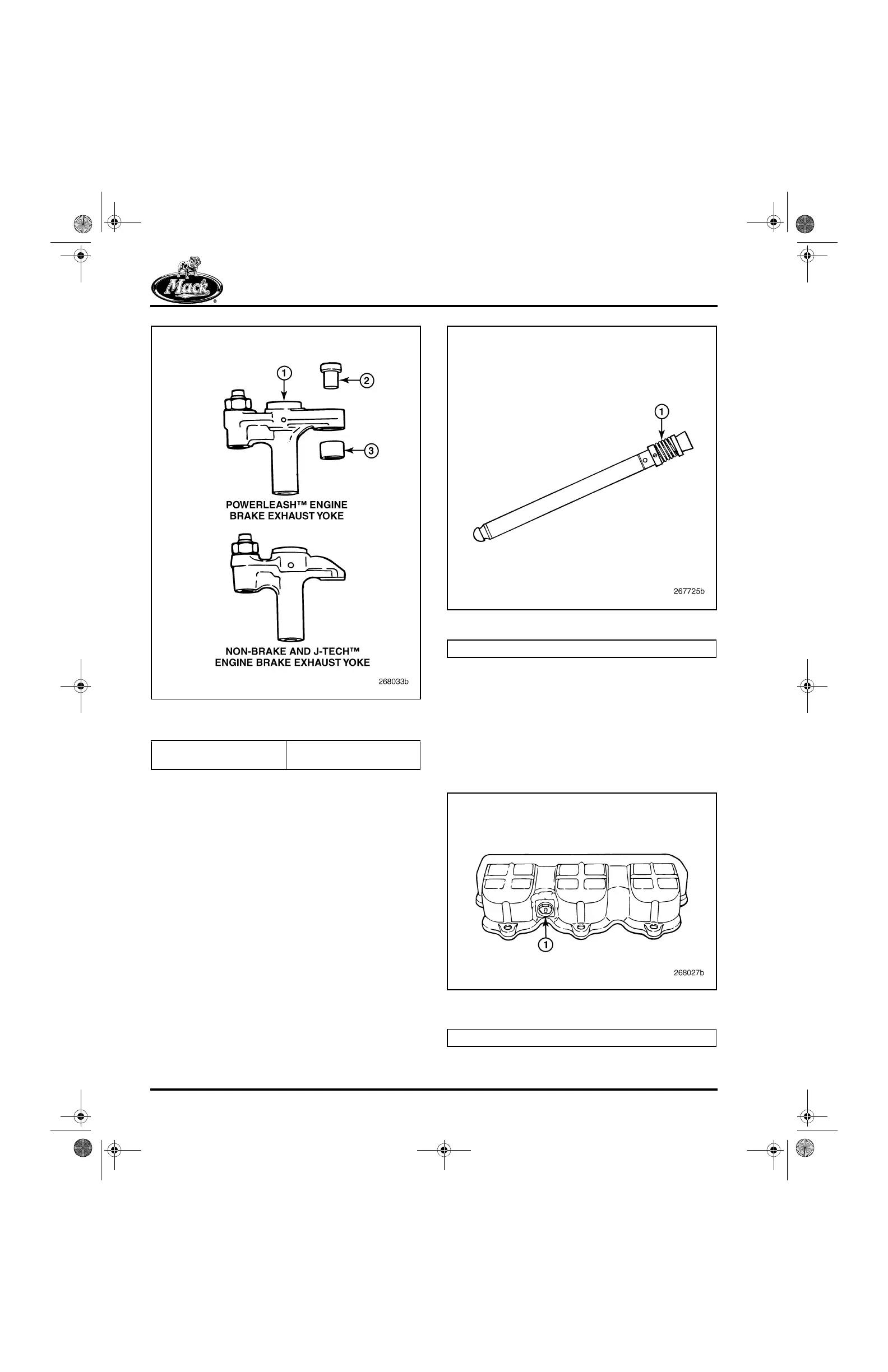

앫 Spring-Loaded Push Rods — To prevent

excessive valve “clatter” created by the

increased exhaust valve lash, and also keep

the lifter roller in contact with the cam lobe,

spring-loaded push rods are used. These

push rod assemblies contain a spring on the

rocker arm end. The spring allows the push

rod to “expand” during the “valve closed” (or

cam sub-base circle) cycle, thus eliminating

excessive lash in the valve train and keeping

the lifter roller in contact with the cam lobe.

During the “valve opening” cycle, the spring

compresses as the lifter roller travels up the

ramp of the cam lobe. The push rod

becomes a “solid assembly” when the

internal stops of the upper and lower push

rod seats make contact. When the push rod

is “solid,” the upward force of the valve lifter

is transmitted to the rocker arm.

50

Figure 50 — Spring-Loaded Push Rod Assembly

앫 Cylinder Head Cover — The MACK

PowerLeash™ engine brake is completely

integrated with the valve train; therefore,

cylinder head cover spacers are not

necessary. The cylinder head cover contains

an electrical pass-through connection that

connects the engine brake solenoid wire to

the engine wiring harness.

51

Figure 51 — Cylinder Head Cover with Electrical

Pass-Through Connection

1. Valve Yoke, Exhaust

2. Actuating Pin

3. Cap, Inboard Exhaust

Valve Stem Tip

1. Push Rod Spring

1. Electrical Pass-Through Connector

5-111.bk Page 50 Monday, July 10, 2006 2:26 PM

Loading...

Loading...