Manitowoc Published 09-09-16, Control # 229-09 10-69

MLC650 SERVICE/MAINTENANCE MANUAL ACCESSORIES

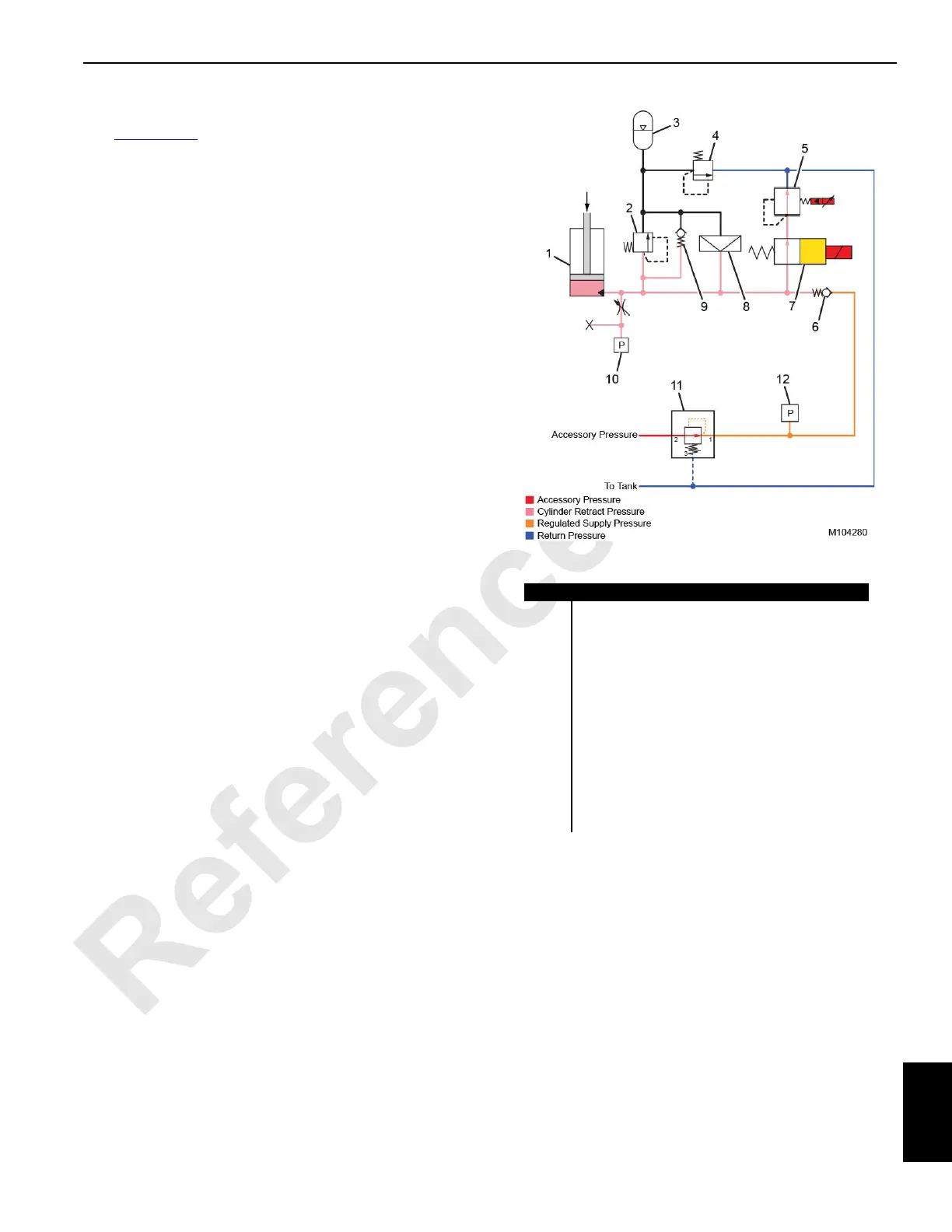

Normal Operation—Cylinder Retraction

See Figure 10-56 for the following.

When the load on the mast stop cylinder increases during

cylinder retraction, the pressure on the bore side of the

cylinder increases. The mast cylinder pressure transducer

(10), located on each cylinder, detects this pressure and

provides a feedback signal to the IOLC30 control module.

At this point, the cylinder pressure is higher than the system

regulated supply pressure. This causes the check valve (6)

to close, preventing hydraulic fluid from flowing back into the

system supply circuit. The IOLC33 control module then

sends a 24 VDC output voltage to the mast cylinder

directional control solenoid valve (7), energizing the

solenoid. The solenoid valve shifts position, allowing

hydraulic fluid to flow to the mast cylinder pressure-reducing

solenoid valve (5). At the same time, the IOLC30 control

module sends a pulse width modulation (PWM) signal to this

solenoid, modulating the solenoid valve to allow the high

pressure oil to flow back to the hydraulic tank. This reduces

the pressure in the cylinder bore until the target pressure is

obtained.

NOTE: When the mast cylinder pressure-reducing

solenoid valve is de-energized, the valve acts as a

relief valve when the pressure becomes equal to or

more than 241 bar (3500 psi). The relief setting

provided by this valve is higher than the maximum

operating pressure provided by the relief valve (2).

Item Description

1 Mast Stop Cylinder

2 Relief Valve (set at 221 bar [3200 psi])

3 Integrated Cylinder Accumulator

4 Relief Valve (set at 16,6 bar [240 psi])

5 Mast Cylinder Pressure-Reducing Solenoid Valve

6 Check Valve

7 Mast Cylinder Directional Control Solenoid Valve

8Rupture Disc

9 Bypass Check Valve

10 Mast Cylinder Pressure Transducer

11 Mast Cylinder System Pressure-Reducing Valve

(set at 31 bar [450 psi])

12 Mast Cylinder System Pressure Transducer

FIGURE 10-56

Cylinder Retraction

Loading...

Loading...