Manitowoc Published 09-09-16, Control # 229-09 2-15

MLC650 SERVICE/MAINTENANCE MANUAL HYDRAULIC SYSTEM

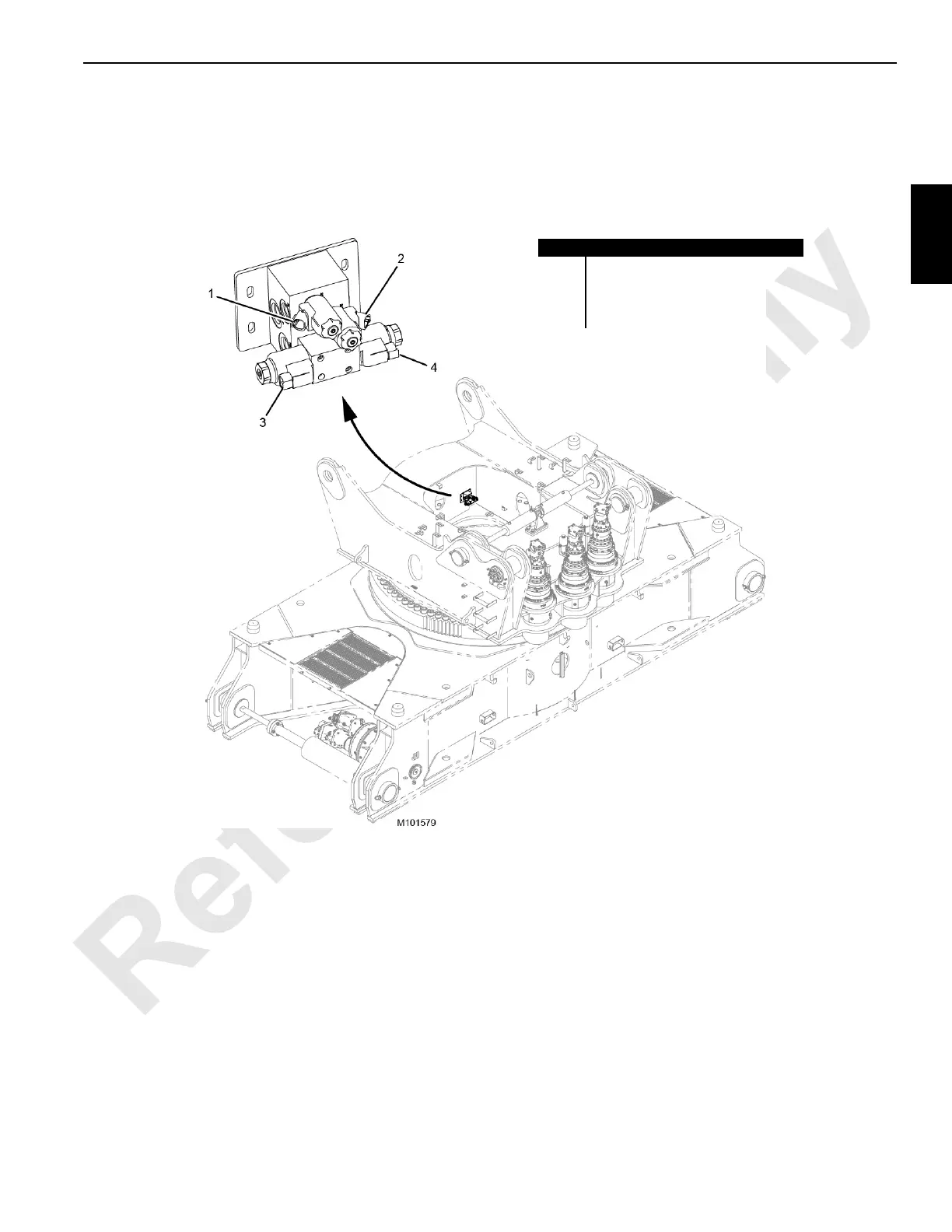

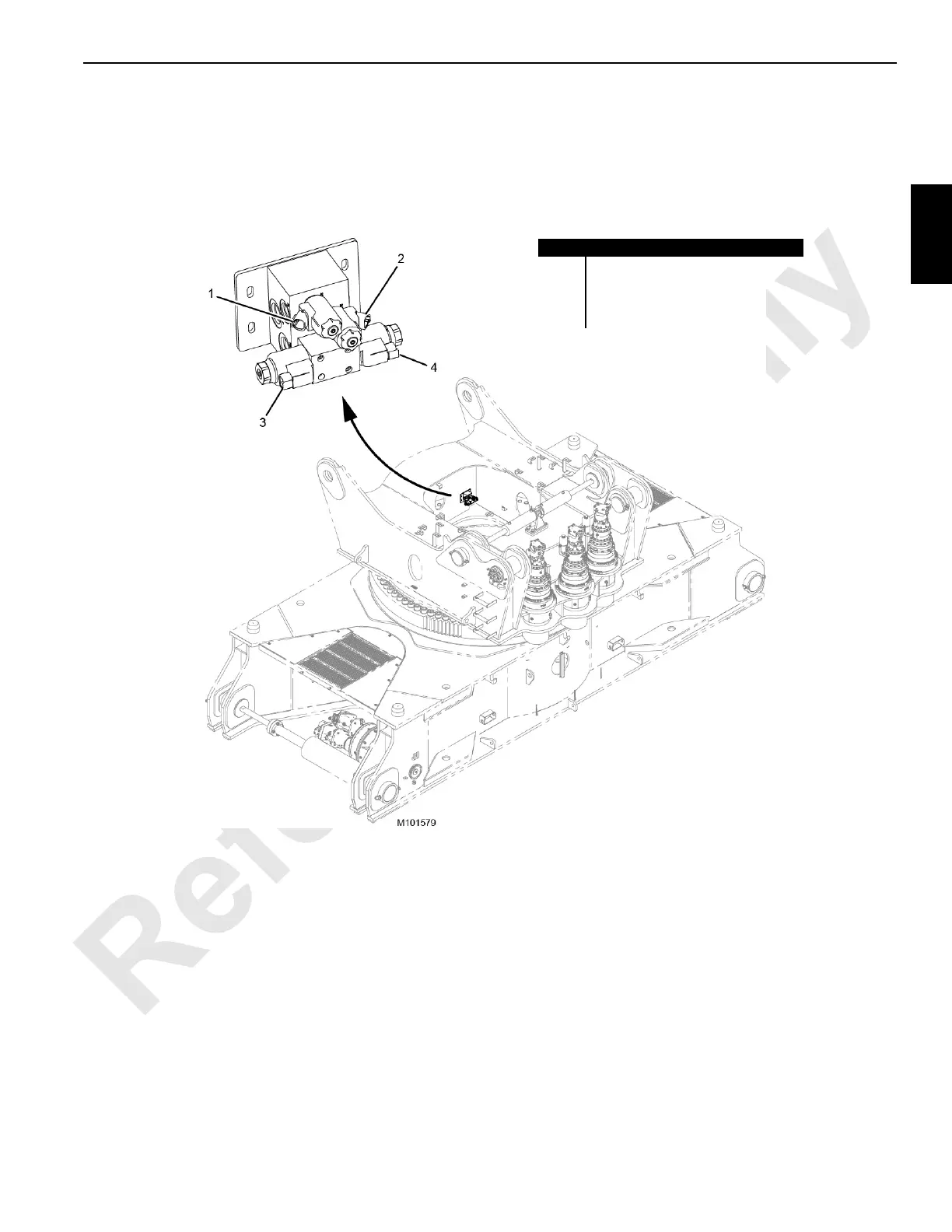

Swing Brake, Travel Brake, and Front

Adapter Pin Pusher Valve Assembly

FIGURE 2-18

Item Description

1 Swing Brake

2Travel Brake

3 Front Adapter Pin Pullers—Extend

4 Front Adapter Pin Pullers—Retract

Loading...

Loading...