HOISTS MLC650 SERVICE/MAINTENANCE MANUAL

5-84

Published 09-09-16, Control # 229-09

.

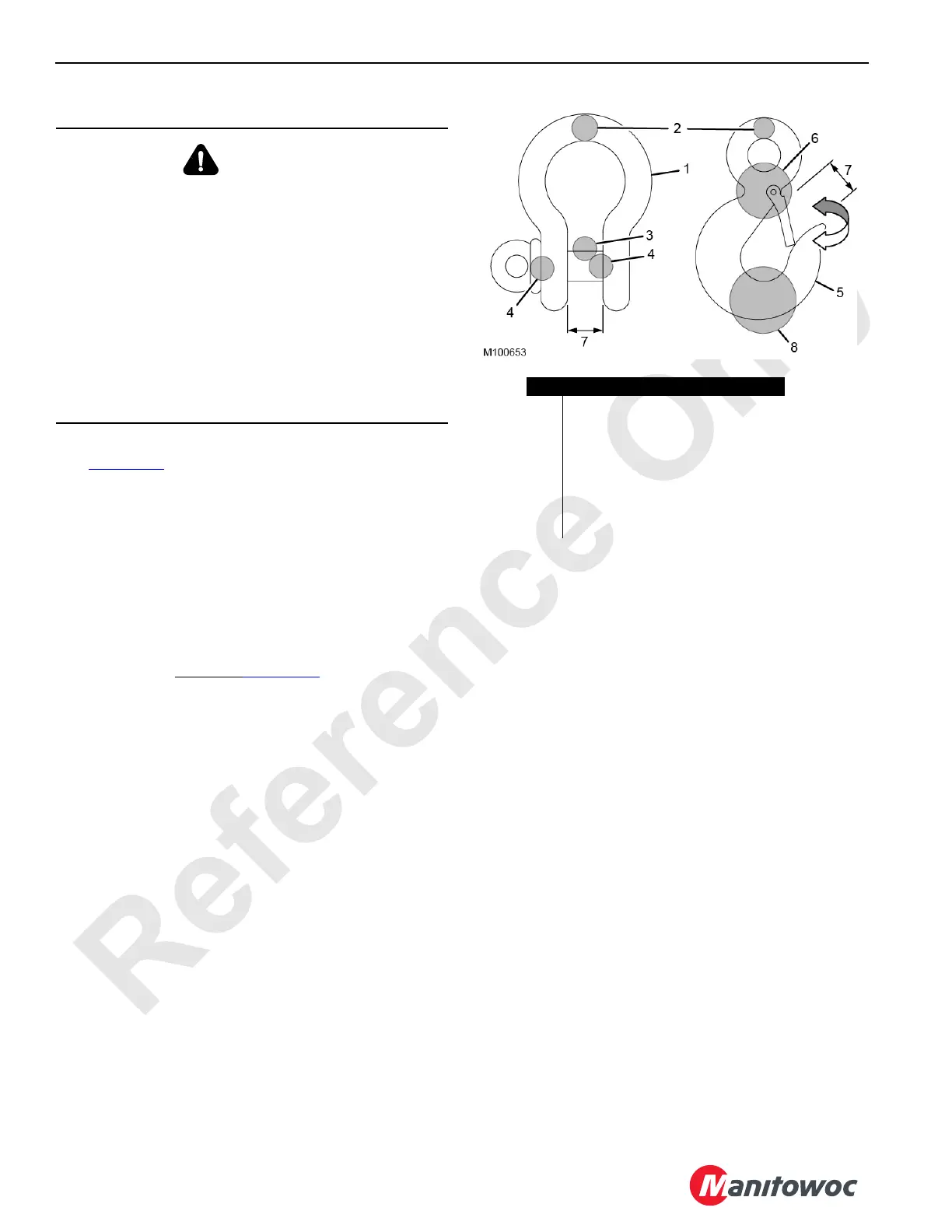

• Inspect each hook and shackle for damage

(Figure 5-53

).

• See the ASME B30-10 Standard for specific hook

replacement guidelines. The standards are available as

follows:

-Mail—ASME, 22 Law Drive, Fairfield, New Jersey,

0700-2900

- Toll-free phone—US & Canada 800-843-2763,

Mexico 95-800-843-2763, Universal 973-882-1167

-Fax—973-882-1717 or 973-882-515

-E-mail— infocentral

@asme.org).

• Contact the supplier of your hooks, shackles, blocks,

and other rigging for repair instructions.

Yearly Inspection

Check each hook and shackle at least yearly for cracks using

one or more of the following methods:

• Dye penetrant test

• MAG particle test

• Ultrasonic test

• X-ray

WARNING

Falling Load Hazard!

To prevent the load from dropping, make sure that, under

slack conditions, the hook latch retains the slings or other

rigging in the hook.

The hook latch is not intended as an anti-fouling device.

Make sure that the hook latch does not support any part of

the load.

Make sure that any slings or other rigging are seated in

the hook. Rigging must never be in a position to foul the

hook latch.

Never disable the hook latch. The hook latch must be

allowed to function as intended.

Item Description

1 Shackle

2 Check for Wear and Deformation

3 Check for Wear and Straightness

4 Check That Pin Is Always Seated

5 Hook

6 Check That Hook Is Not Twisted

7 Check for Cracks and Twisting

8 Check for Wear and Cracks

FIGURE 5-53

Loading...

Loading...