CYLINDER HEAD

90-857046R1 NOVEMBER 2001 Page 4A-5

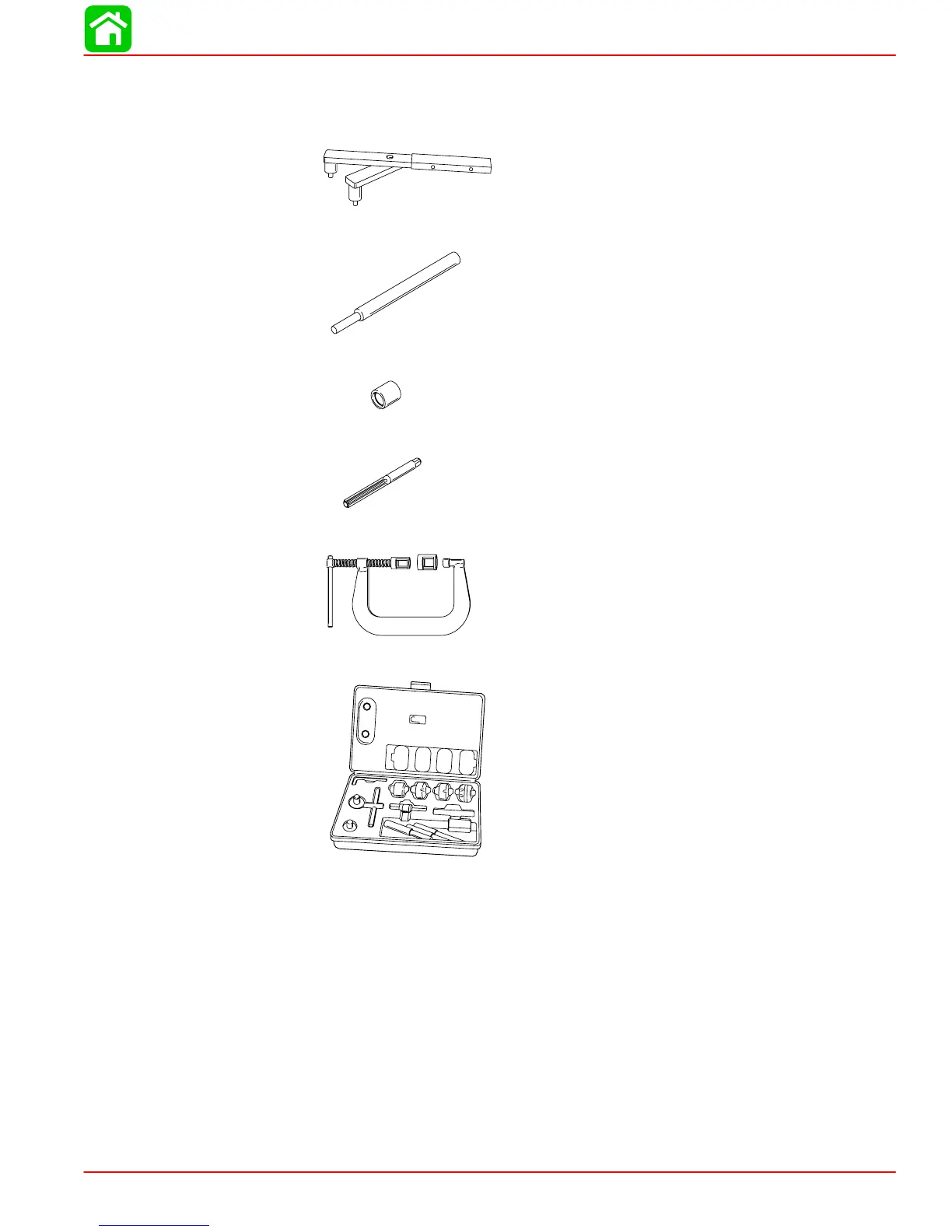

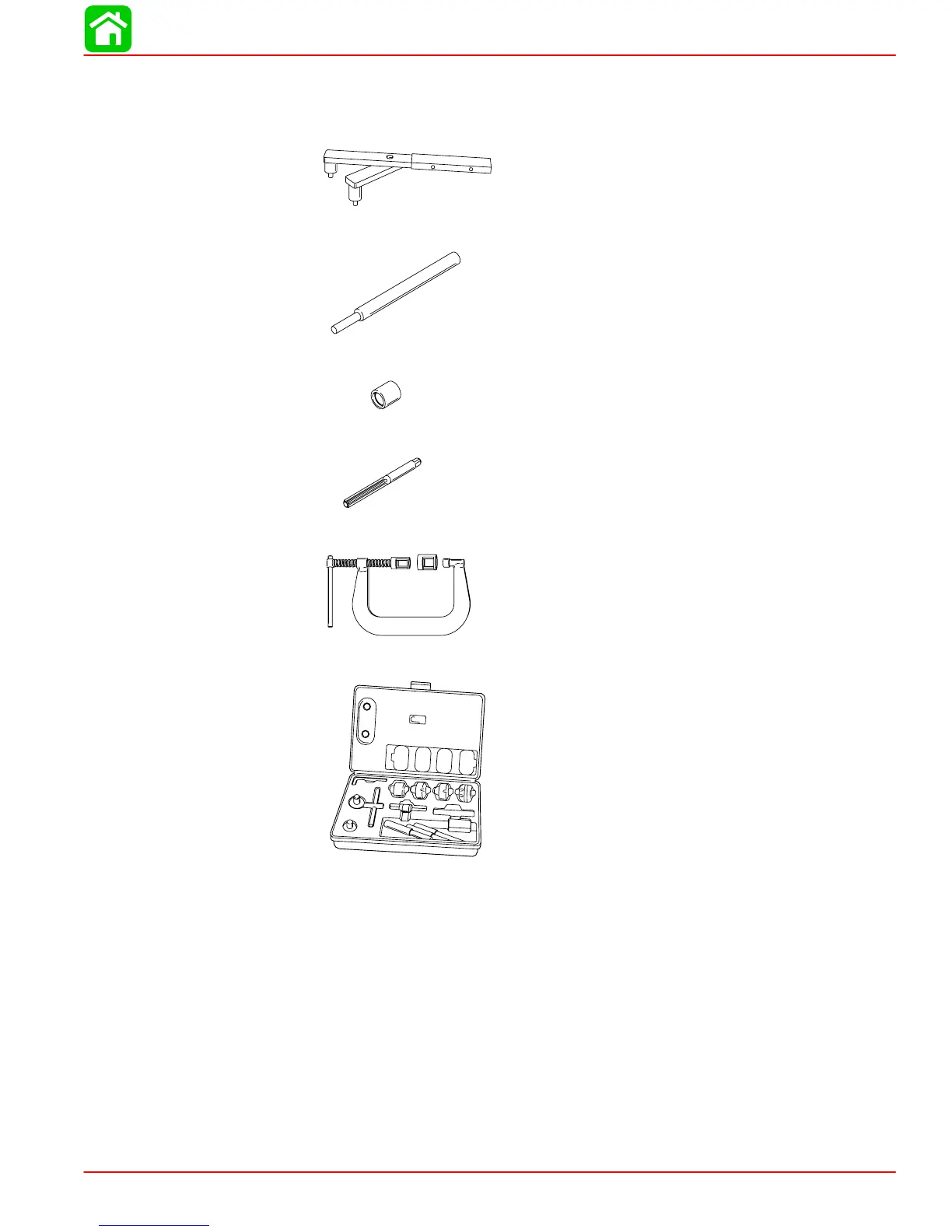

Special Tools

1. Flywheel Holder P/N 91-83163M

2. Valve Guide Remover P/N 91-809495A1

3. Valve Guide Installer Bushing P/N 91-809496A1

4. Valve Guide Reamer P/N 91-809497A1

5. Valve Spring Compressor P/N 91-809494A1

6. Valve Seat Cutter Kit (Obtain Locally).

Loading...

Loading...