CYLINDER HEAD

Page 4A-32 90-857046R1 NOVEMBER 2001

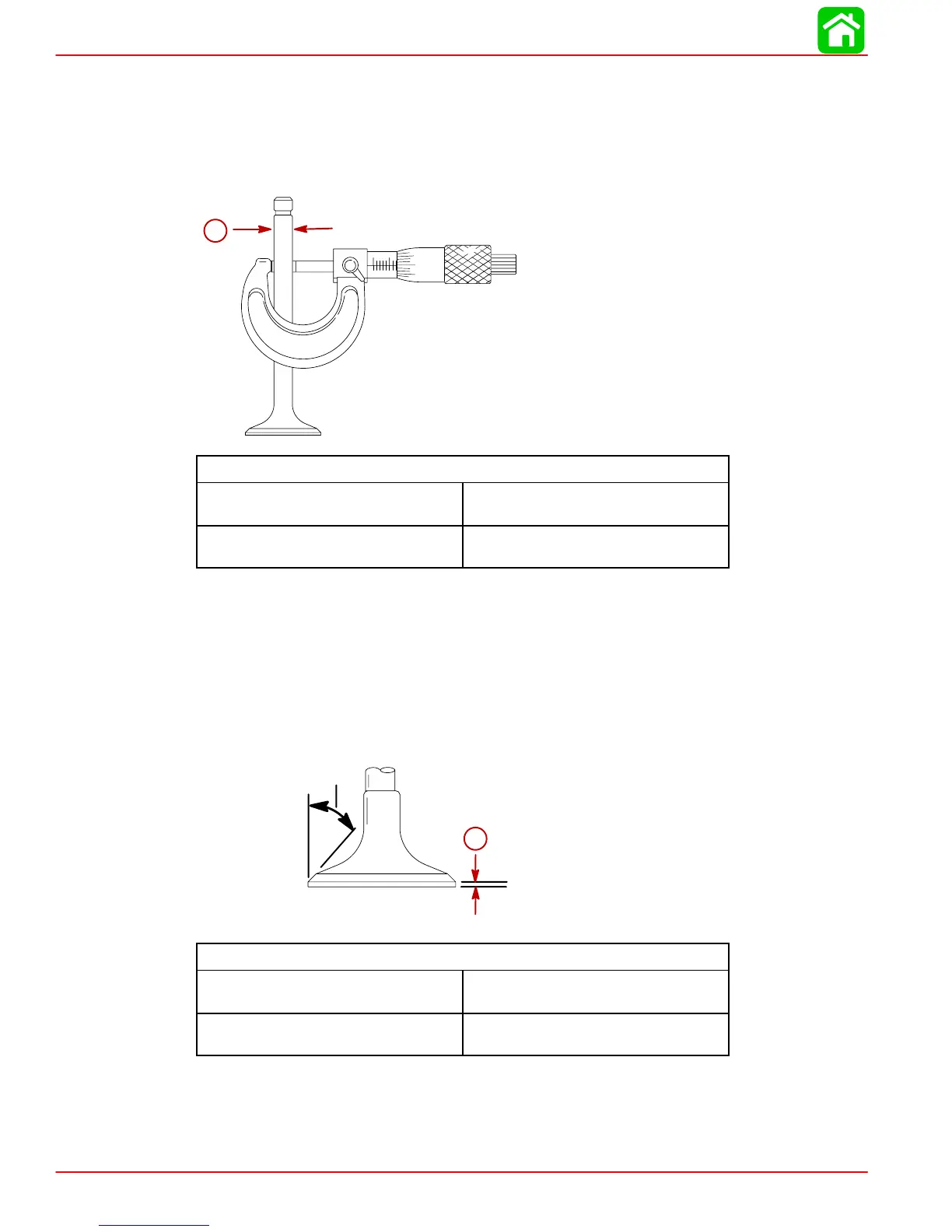

Valves

1. Clean the carbon deposits from the valve. Discard any cracked, warped, or burned

valves.

2. Measure the valve stem diameter to check for wear. Replace valves if not within specifi-

cation.

a

Valve Stem Diameter

Intake Valve 0.2156 - 0.2161 in.

(5.475 - 5.490 mm)

Exhaust Valve 0.2150 - 0.2156 in.

(5.460 - 5.475 mm)

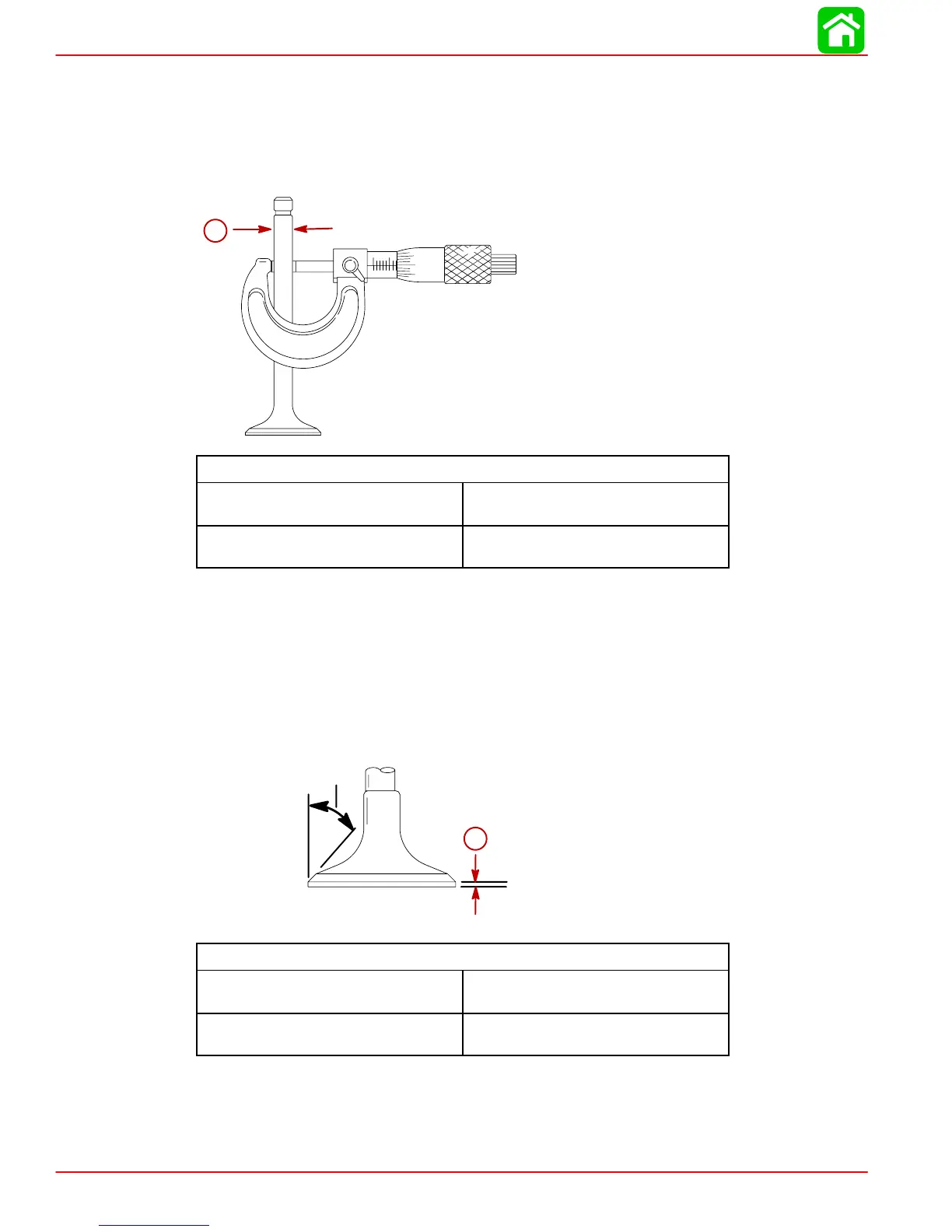

3. Check the valve face for pitting. Valves faces that are pitted must be refaced.

NOTE: Several different types of equipment are available for refacing valves. Follow the

equipment manufacturer’s instructions.

NOTE: After refacing the valve seat or replacing the valve and valve guide, the valve seat

and valve face should be lapped.

4. Check the margin thickness (a) of the valves after the valves have been ground. Any

valve with a margin thickness of less than the specification, should be replaced.

45

°

a

Margin Thickness “a”

Intake Valve 0.020 - 0.035 in.

(0.5 - 0.9 mm)

Exhaust Valve 0.020 - 0.035 in.

(0.5 - 0.9 mm)

Loading...

Loading...