CYLINDER BLOCK/CRANKCASE

Page 4B-1790-857046R1 NOVEMBER 2001

Inspection

Cylinder Bore

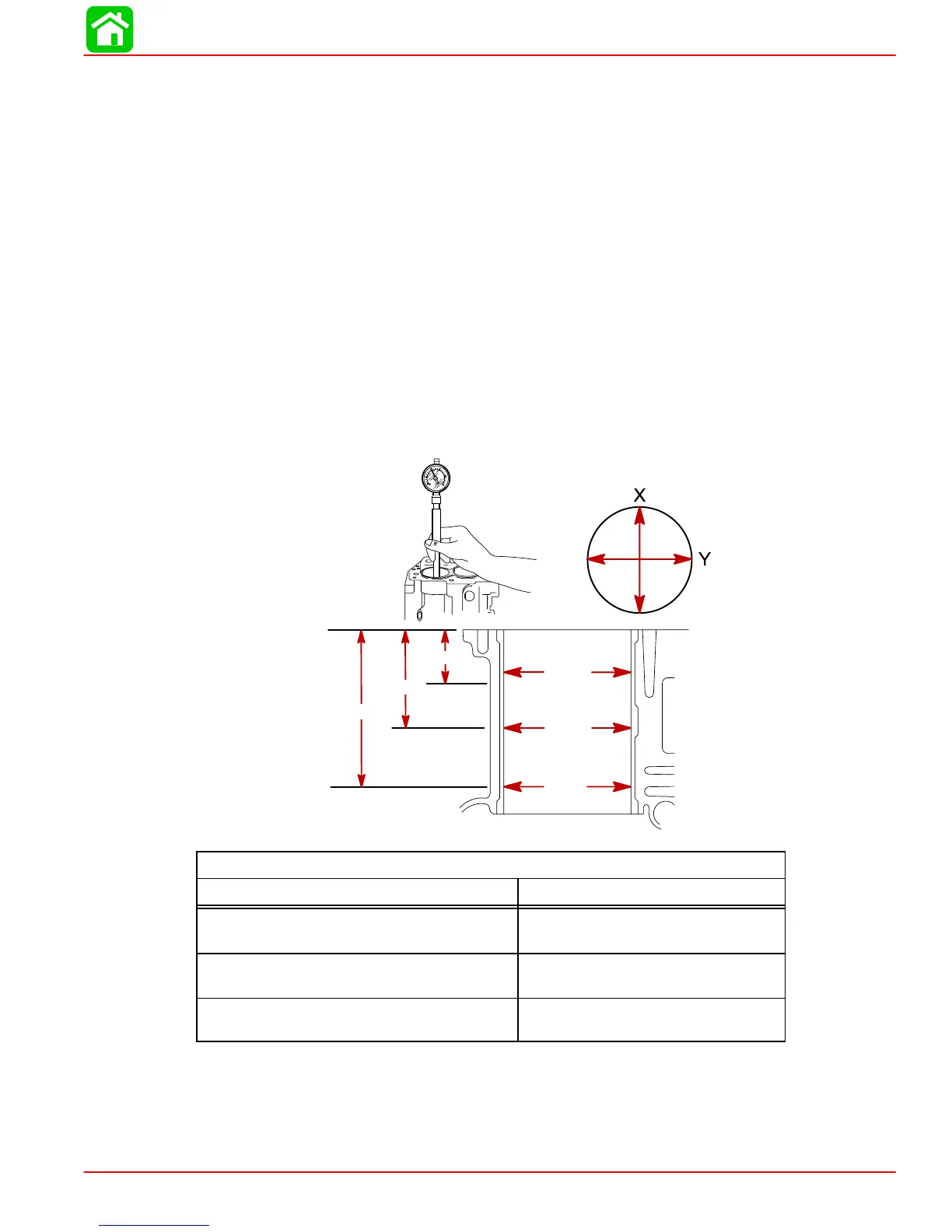

MEASURING CYLINDER BORE

1. Measure the cylinder bore diameter at three locations in both X and Y axis.

2. If the cylinder bore is beyond the standard limits listed in the tables below, it will be nec-

essary to re-bore the cylinder to accept the oversize piston.

NOTE: Measure at three locations (L

1

, L

2

, and L

3

) in both X and Y axis (D

1-6

).

L

1

=0.8 in. (20 mm)

L

2

=1.6 in. (40 mm)

L

3

=2.4 in. (60 mm)

1. Inspect:

a. Water jacket for mineral deposits/corrosion, clean if necessary.

b. Inner surface for score marks, repair if necessary.

2. Measure bore diameter with a cylinder gauge, re-bore or replace if necessary.

55837

D

1,2

D

3,4

D

5,6

L

1

L

2

L

3

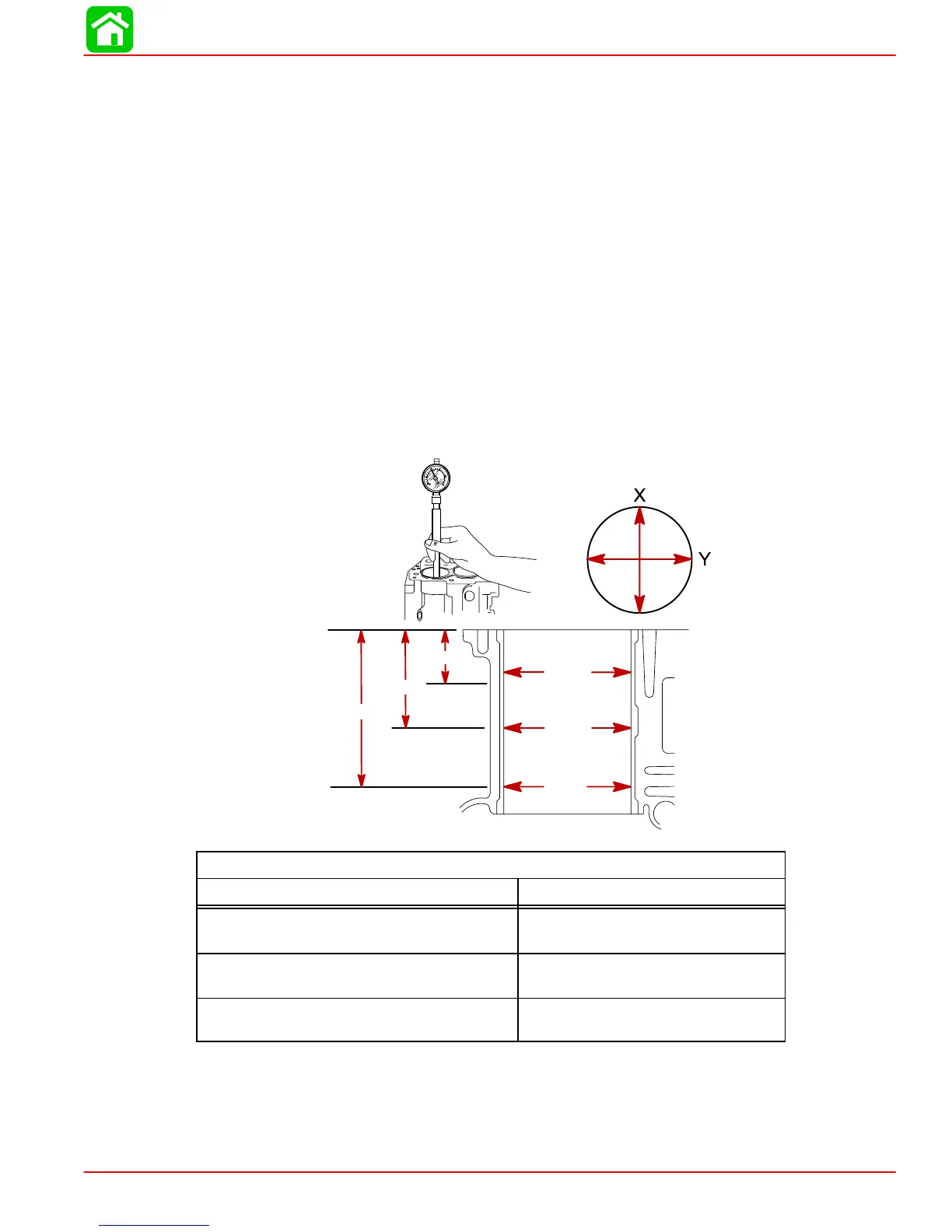

Cylinder Bore Specifications

Bore Size Maximum Taper/Out-of-Round

Standard Bore

2.5591 in. (65 mm)

0.003 in.(0.08 mm)

Oversize Bore-0.010 in. (0.25 mm)

2.5689 in. (65.25 mm)

0.003 in.(0.08 mm)

Oversize Bore-0.020 in. (0.50 mm)

2.5787 in. (65.5 mm)

0.003 in.(0.08 mm)

NOTE: Taper=(Maximum of D

1

or D

2

)–(Minimum of D

5

or D

6

)

Loading...

Loading...