NICE3000

new

User Manual

6 System Commissioning and Functions

- 125 -

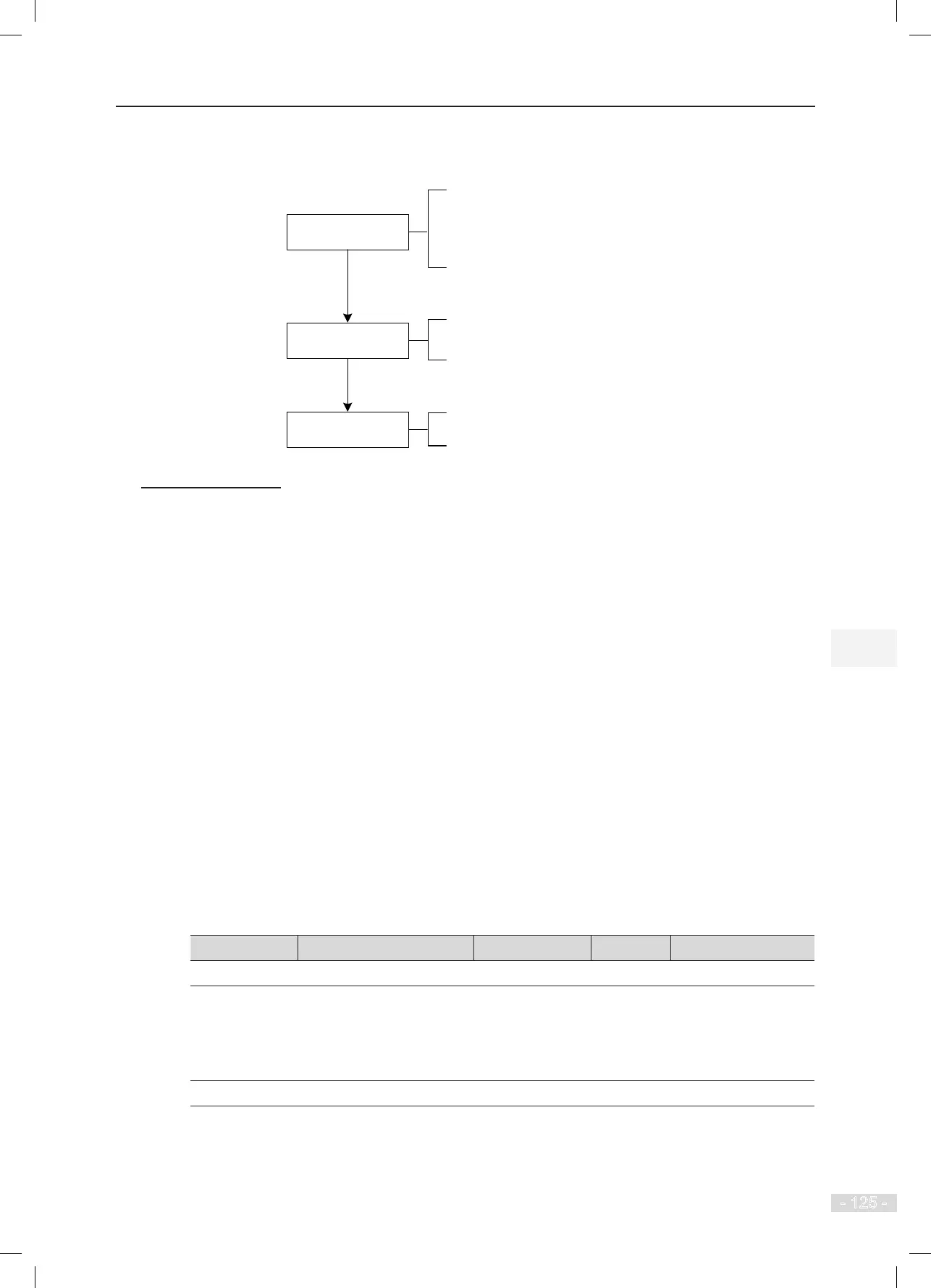

6.1.4 Commissioning at Normal Speed

1. Light curtain commissioning

2. Door machine controller

commissioning

1. HCB installation

2. HCB address setting

1. Make preparations.

2. Check that shaft auto-tuning

conditions are met.

3. Perform shaft auto-

tuning

.

4. Perform running test at normal

speed.

Shaft auto-tuning

Car top

commissioning

HCB installation

and setting

◆

Shat Auto-tuning

1. Make preparations for shaft auto-tuning.

● Check that the shaft switches act properly, including nal limit switches, limit switches, slow-

down switches, and leveling sensors.

● Check that the acting sequence of the leveling sensors is correct.

Generally, one leveling sensor is installed. If multiple leveling sensors are installed, check that the

acting sequence is correct. Take the situation with three sensors as an example:

Acting sequence of sensors at inspection up: up leveling sensor → door zone sensor → down

leveling sensor

Acting sequence of sensors at inspection down: down leveling sensor → door zone sensor → up

leveling sensor

● Check CANbus communication state. If fault E51 is not reported and the COP indicator on the

MCB is steady ON, it indicates that CANbus communication between the MCB and the CTB

is normal. If CANbus communication is abnormal, rectify fault E51 according to the solution

described in Chapter 9.

● Set the related parameters.

Function Code Parameter Name Setting Range Default Remarks

F0-04 Rated elevator speed 0.250–4.000 m/s 1.600 m/s -

F6-00 Top oor of the elevator F6-01 to 40 9

Set it to the actual

number of oors

(number of actually

installed leveling

plates).

F6-01 Bottom oor of the elevator 1 to F6-00 1 -

Loading...

Loading...