NICE3000

new

User Manual 12 EMC

- 311 -

●

The cable ducts must be in good connection and well grounded. Aluminium ducts can be used to

improve electric potential.

●

The lter, controller and motor should be connected to the system (machinery or appliance)

properly, with spraying protection at the installation part and conductive metal in full contact.

For more cabling details, see section 3.2.

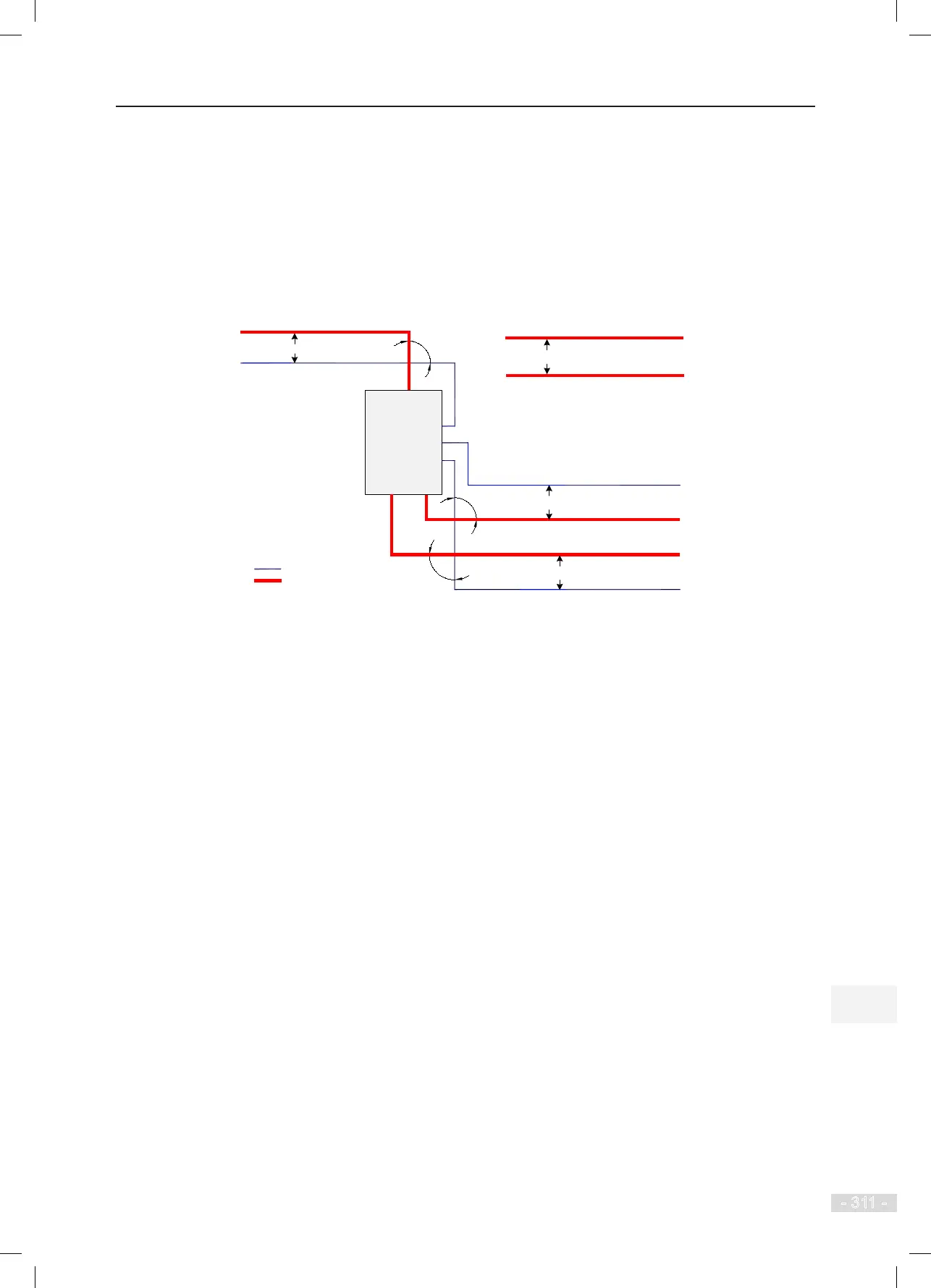

The following gure shows the recommended cabling diagram.

NICE3000

new

integrated

elevator

controller

Min. 200 mm

Min. 300 mm

Power cable

Motor cable

Min. 500 mm

Min. 500 mm

Regen. resistor cable

Motor cable

Power cable

90°

90°

90°

Control cable

Control cable

Power cable

Control cable

Control cable

12.8 Solutions to Current Leakage

The controller outputs high-speed pulse voltage, producing high-frequency leakage current during running

of the controller. Each controller produces above 100 mA leakage current. Therefore, it is necessary to

select an ELCB with rated operating current of 100 mA above.

The controller generates DC leakage current in protective conductor. In this case, a time-delay B-type

ELCB must be used. If multiple controllers are used, an ELCB must be provided for each controller.

The factors that inuence the leakage current are as follows:

●

Controller capacity

●

Carrier frequency

●

Type and length of motor cable

●

EMI lter

When the leakage current causes the ELCB to act, you should:

●

Increase the sensitivity current of the ELCB.

●

Replace it with a time-delay B-type ELCB with high-frequency suppression function.

●

Reduce the carrier frequency.

●

Shorten the length of the output cables.

●

Install a current leakage suppression device.

●

Use Chint Electric and Schneider brands.

Loading...

Loading...