SECTION 3

TOUCHSCREEN AND TOOLBOX OPERATION

23

Results:

Error in red – There is a problem with that system (For example, a disconnected wire harness, or worn or

broken component.)

Red number – There is an issue with that system or component. It may be a loose connection or indication

that the component is about to fail. If the result is larger than the target number on systems with belts

(Feeder, Printzone, Sled, Printhead and Clamshell); the belt(s) are probably too tight and need adjusting.

If the result matches the target number, but the number is red, that system will function normally. However,

adjusting the belts on that system to run at a lower number might increase component life. After adjusting

the belt(s), and/or replacing a component, retest the system(s) involved until all systems are green.

Green number or OK – The system is operating within its optimum range. No further action is needed.

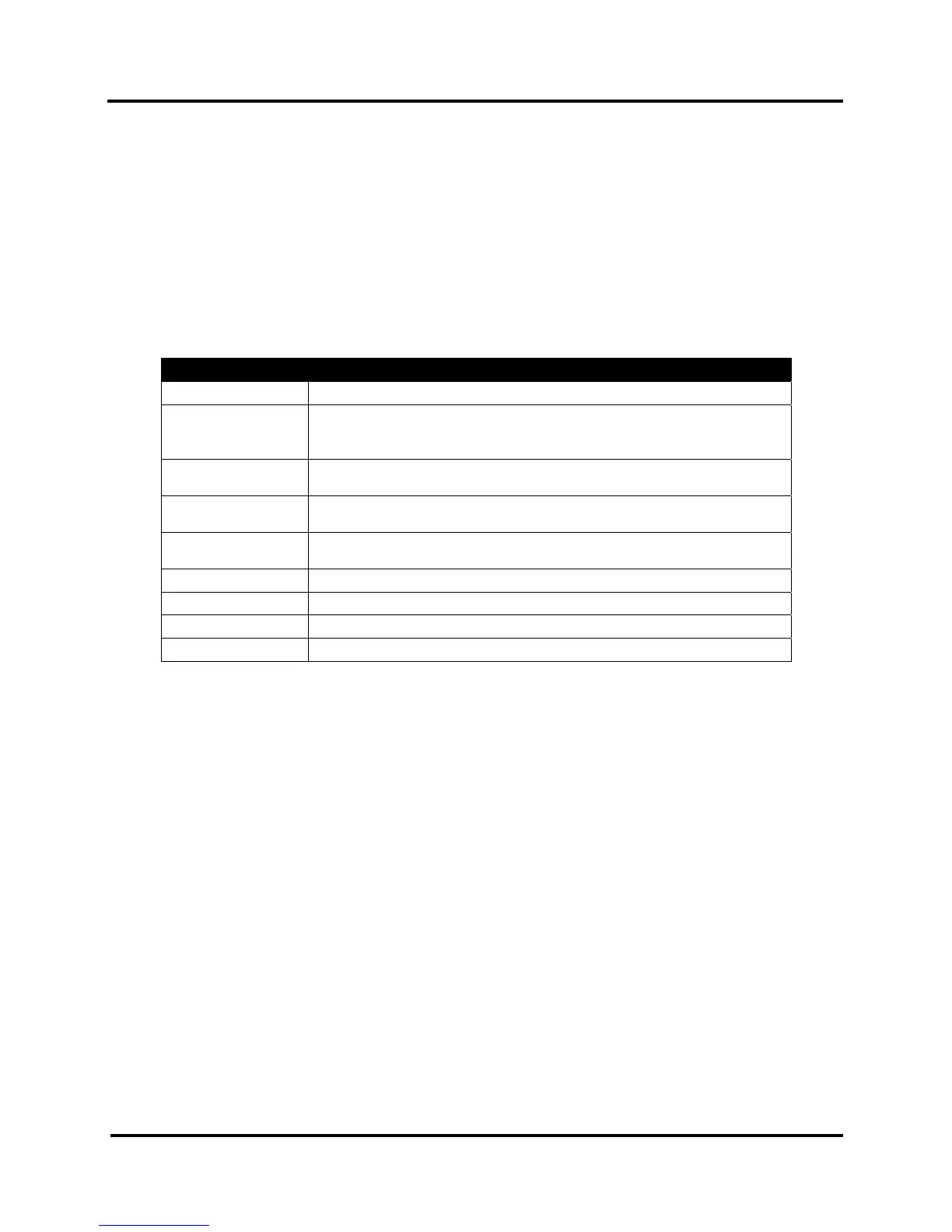

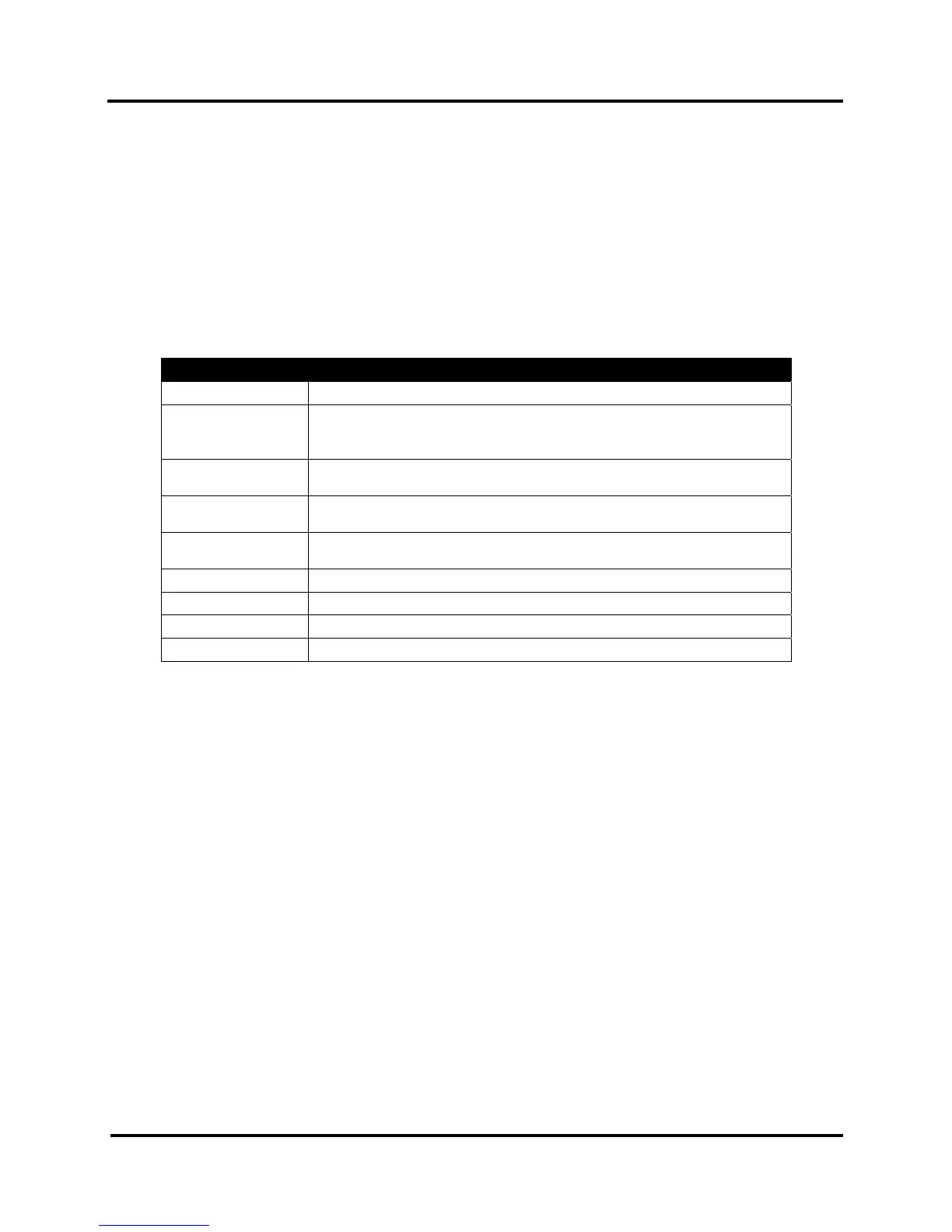

Test Name Components/Systems Tested

Feeder

Feed Roller Belts Tension, Feed Roller Motor and Belt Tension

Printzone

Paperpath Motor, Paperpath Motor Belt Tension, Print,

Intermediate and Exit Roller Belt Tension; Exit Conveyor Drive Belt

Tension

Sled (Lift)

Service Station Position Motor, Service Station Motor Belt Tension

and Service Station Position Belts Tension

Printhead (Lift)

Printhead Lift Motor, Printhead Motor Belts Tension, Printhead Lift

Belts Tension

Clamshell

Media Thickness mechanism? (Media Thickness Motor, Motor Belt

Tension and Media Thickness Lift Belt Tension)

Ink Pump

Peristaltic Pump

Sump

Ink Waste Pump

Valve

Dual Pinch Valve

Wiper

Wiper Motor

Loading...

Loading...