SECTION 4

ADJUSTMENTS

38

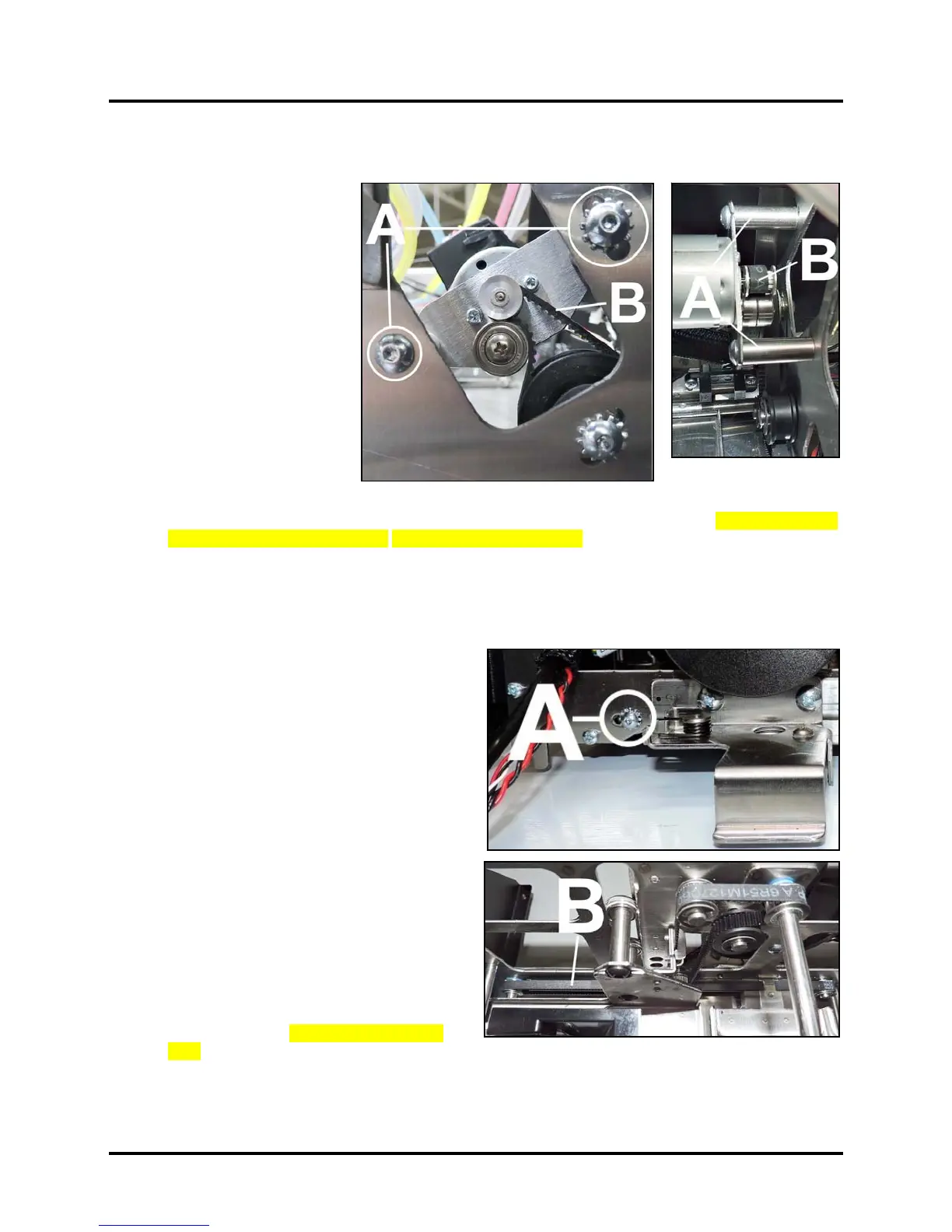

Service Station Motor Drive Belt Tension Adjustment

1. Remove the Top Assembly

Rear Cover.

2. Open the Top Cover.

3. Loosen (2) screws [A]

securing the Service Station

Motor Assembly to the Top

Assembly Frame.

4. Move Idler Pulley Assembly

up or down to tension the

Motor Drive Belt [B].

When properly tensioned,

there should be about 1/8"

of deflection in the Belt.

Move the Belt back and

forth to reset the Belt

position and check for

additional slack. Recheck and retension the Belt as necessary.

NOTE: This adjustment is only an approximation, further adjustment may be necessary. See “Testing Belt

Tension” at the end of this section. System Test: Press Sled Test.

5. Tighten Idler Pulley screw.

6. Reinstall Control Panel Cover.

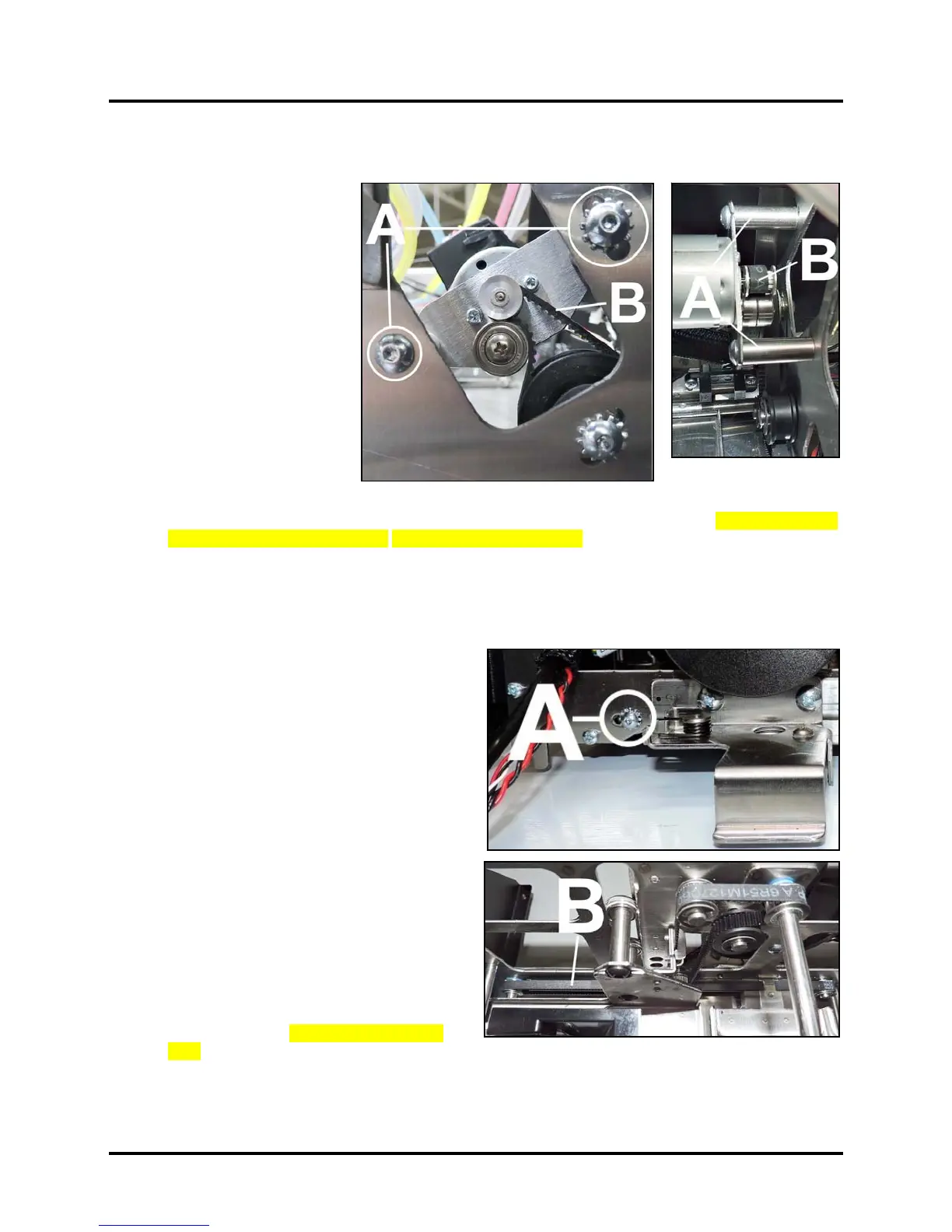

Service Station Positioning Belts Tension Adjustment

NOTE: To ensure proper Printer operation, it is

recommended that you check/adjust both Service

Station Positioning Belts at the same time.

1. Remove the Control Panel Cover and Top

Assembly Rear Cover.

2. Open the Top Cover.

Operator Side:

3. Loosen Service Station Positioning Belt Tension

Pulley [A] (1 screw).

4. Move Pulley Assembly right or

left to tension the Positioning Belt [B]. When

properly tensioned, there should be about 1/8"

of deflection in the Belt. Move the Belt back

and forth to reset the Belt position and check for

additional slack. Recheck and retension the Belt

as necessary.

NOTE: This adjustment is only an

approximation, further adjustment may be

necessary. See “Testing Belt Tension” at the

end of this section. System Test: Press Sled

Test.

5. Tighten Position Belt Tension Pulley screw.

6. Reinstall Control Panel Cover.

Loading...

Loading...