SECTION 4

ADJUSTMENTS

40

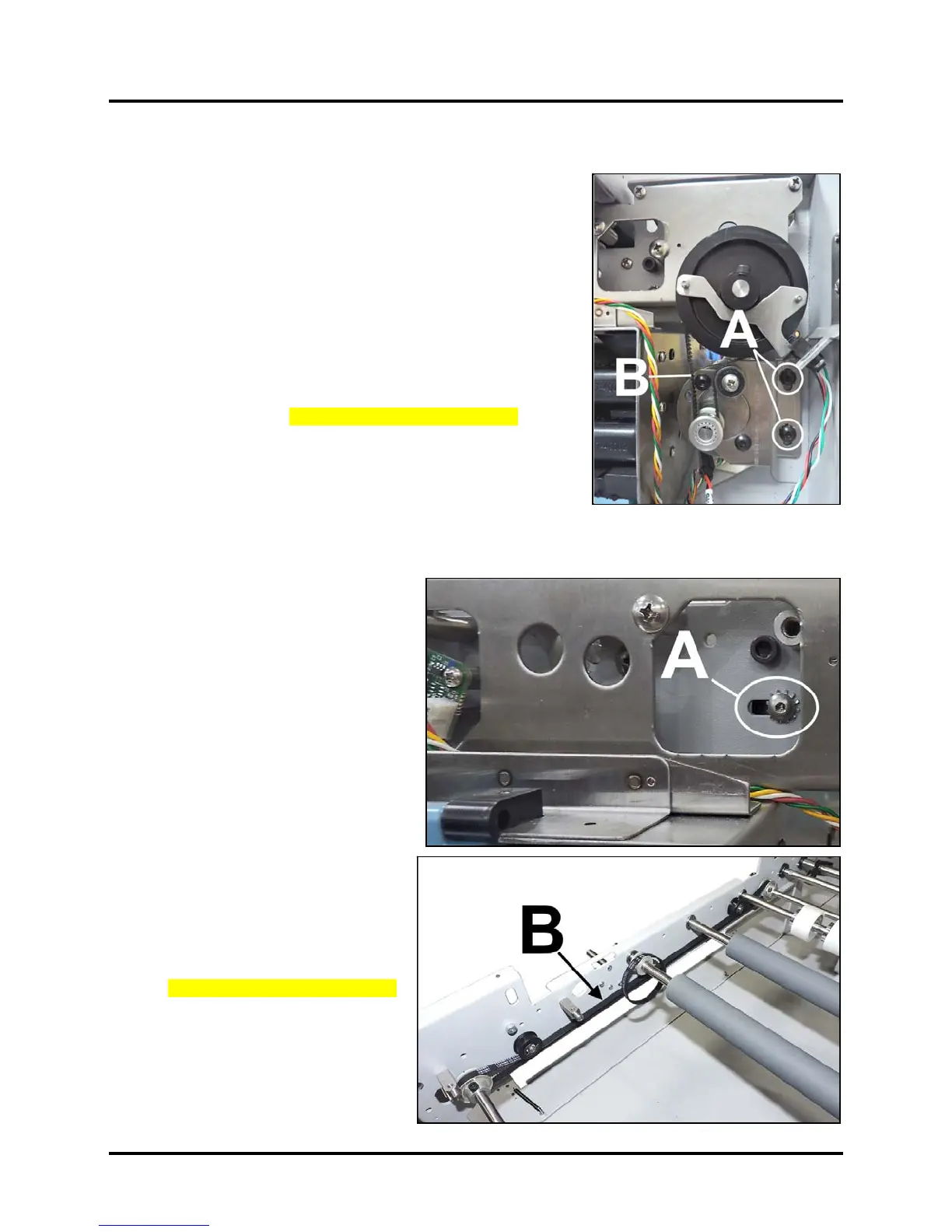

Media Thickness Adjustment Lift Motor Drive Belt Tension Adjustment

1. Open the Ink Tank Door. Raise the Top Assembly.

2. Remove the Left-hand Operator Side Cover.

3. Loosen (2) screws [A] securing the Media Thickness Lift Motor

to the Printer Side Frame.

4. Move the Motor up or down in the slots to tension the Belt [B].

When properly tensioned, there should be about 1/8" of

deflection in the Belts. Move the Belt back and forth to reset the

Belt position and check for additional slack. Recheck and

retension the Belt as necessary.

NOTE: This adjustment is only an approximation, further

adjustment may be necessary. See “Testing Belt Tension” at the

end of this section. System Test: Press Clamshell Test.

5. Tighten the mounting screws.

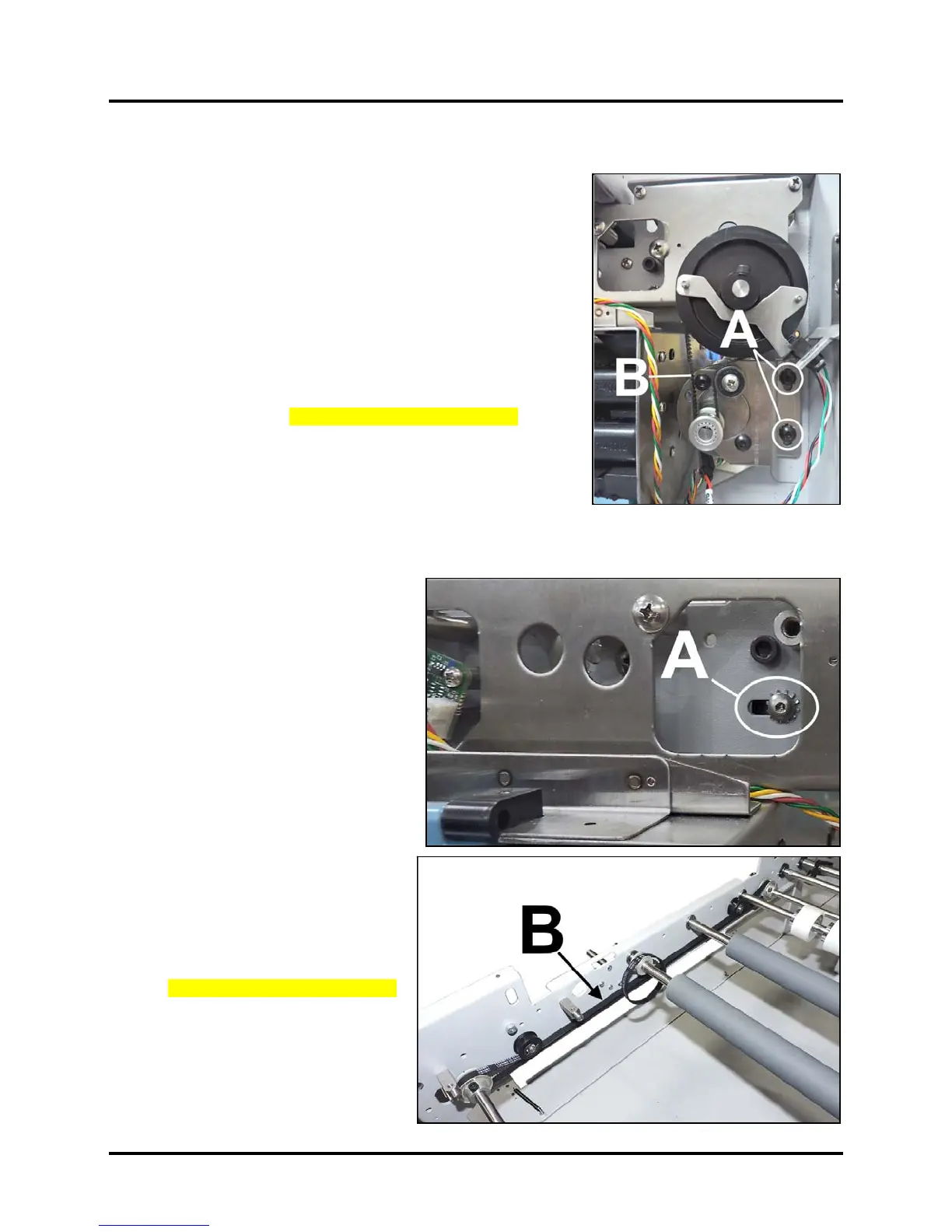

Media Thickness Adjustment Lift Belt Tension Adjustment

1. Open the Ink Tank Door. Raise the

Top Assembly.

2. Remove the Left-hand Operator Side

Cover. Remove the Non-Operator Side

Cover.

3. Remove the Paper Path Plate.

4. Loosen the Media Thickness Lift Belt

pulley mounting screw [A].

5. Move Pulley Assembly right or left to

tension the Belt [B]. When properly

tensioned, there should be about 1/8"

of deflection in the Belt. Move the

Belt back and forth to reset the Belt

position and check for additional

slack. Recheck and retension the Belt

as necessary.

NOTE: This adjustment is only an

approximation, further adjustment

may be necessary. See “Testing Belt

Tension” at the end of this section.

System Test: Press Clamshell Test.

Loading...

Loading...