Technical Reference Guide – Appendix D – Media specifications > 241

2. The length-to-width ratio of paper is 1 : 2/3 – 2.

3. Use paper that is neither folded nor distorted.

4. Glue should be applied to the insertion end of each form.

5. For paper with binding holes, see “Binding holes” on

page 235.

6. Printing accuracy is assured from 6.35 mm (1/4 in)

(inclusive) from each edge.

7. NEVER process and use continuous paper as single paper/

cut-sheet.

P

APER

QUALITY

The following paper quality is usable:

NOTE

Paper smoothness is between 90 and 7 seconds.

For paper types other than the above, adequate prior testing

should be carried out to ensure that the paper types do not

create problems.

P

APER

WEIGHT

AND

MAX

.

NO

.

OF

FORM

PARTS

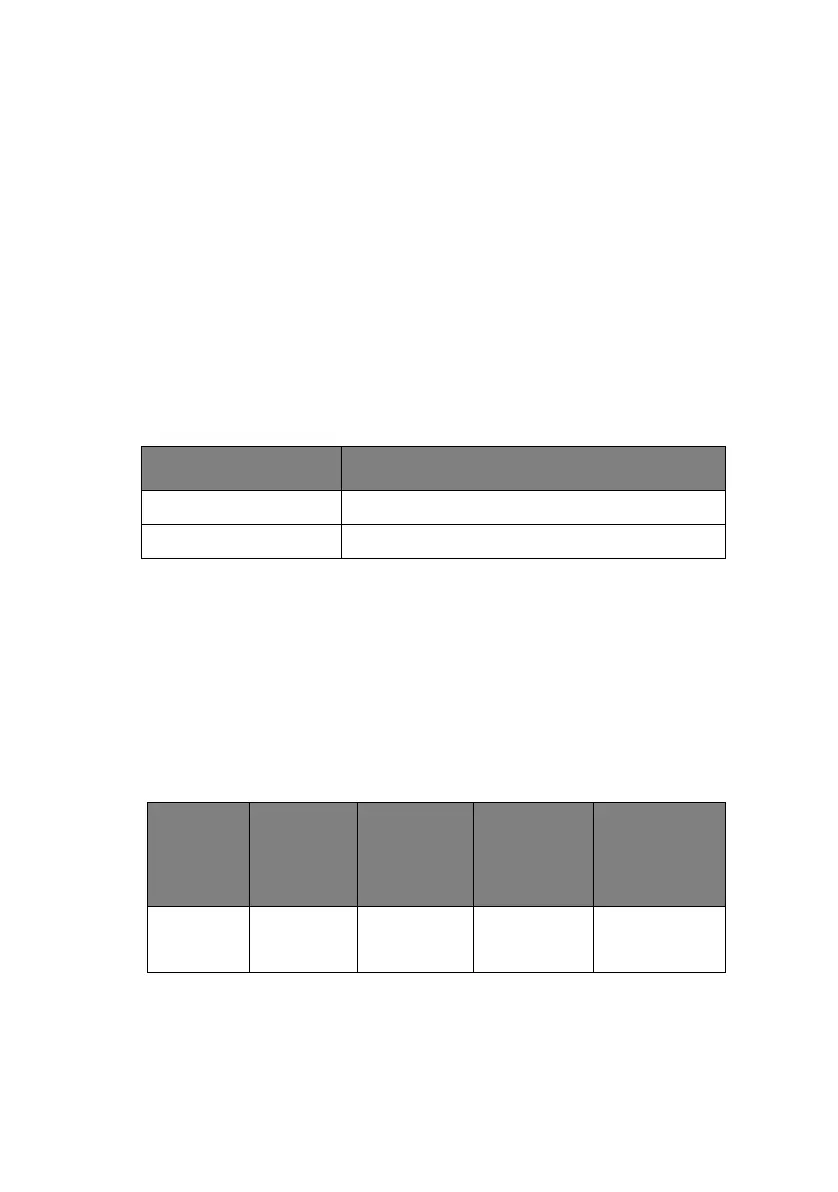

The following table shows usable paper weights and the

maximum number of form parts:

TYPE PAPER QUALITY

Single-part form White, high quality paper

Multipart form Pressure-sensitive paper, carbon-backed paper

TYPE PAPER

QUALITY

WEIGHT

(NOTE 1)

MAXIMUM

NUMBER

OF FORM

PARTS

TOTAL

PAPER

THICKNESS

Single-part

form

High quality

paper

45 to 70 kg

(52 to 90

gsm)

––

Loading...

Loading...