Technical Reference Guide – Appendix D – Media specifications > 230

NOTE

1. Interleaved paper is a multipart form with carbon paper

interleaved.

Paper smoothness is within 100 seconds.

For paper other than the above, it is advised that adequate prior

testing is performed to ensure the paper does not present

problems.

P

APER

WEIGHT

AND

MAX

.

NO

.

OF

FORM

PARTS

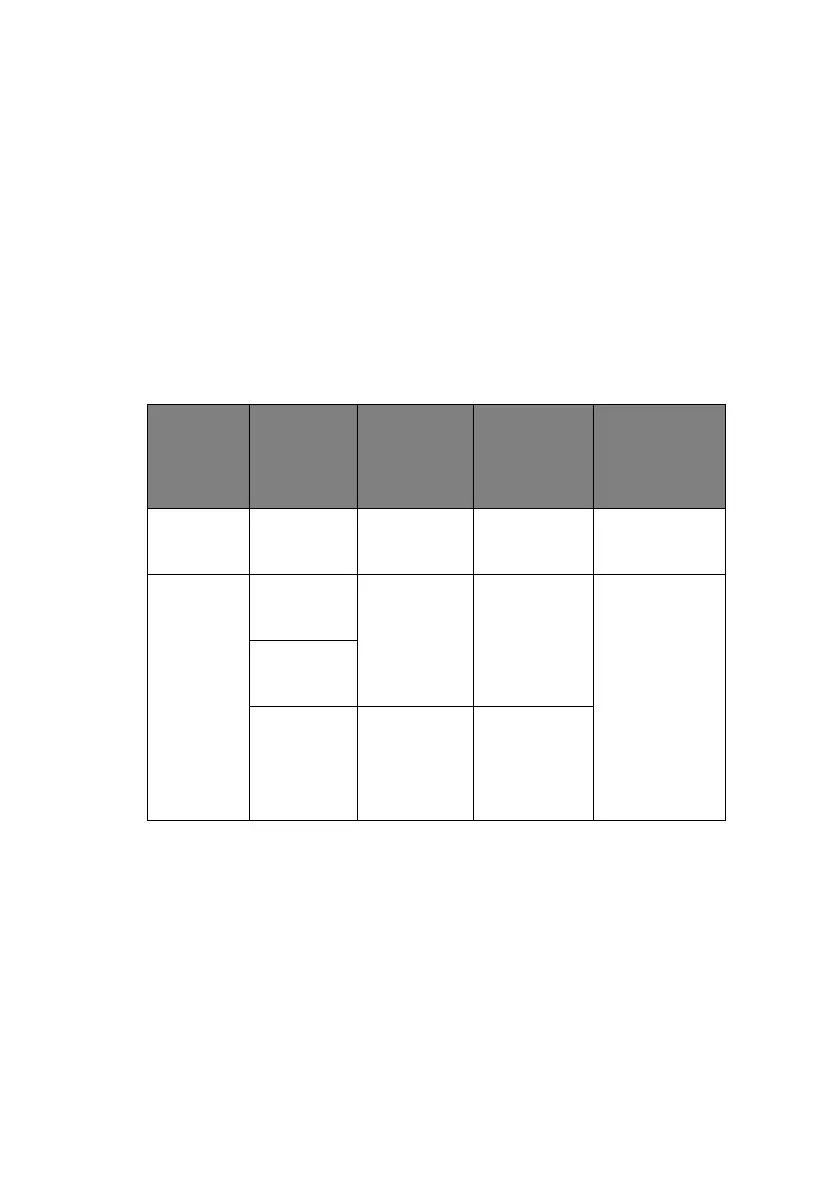

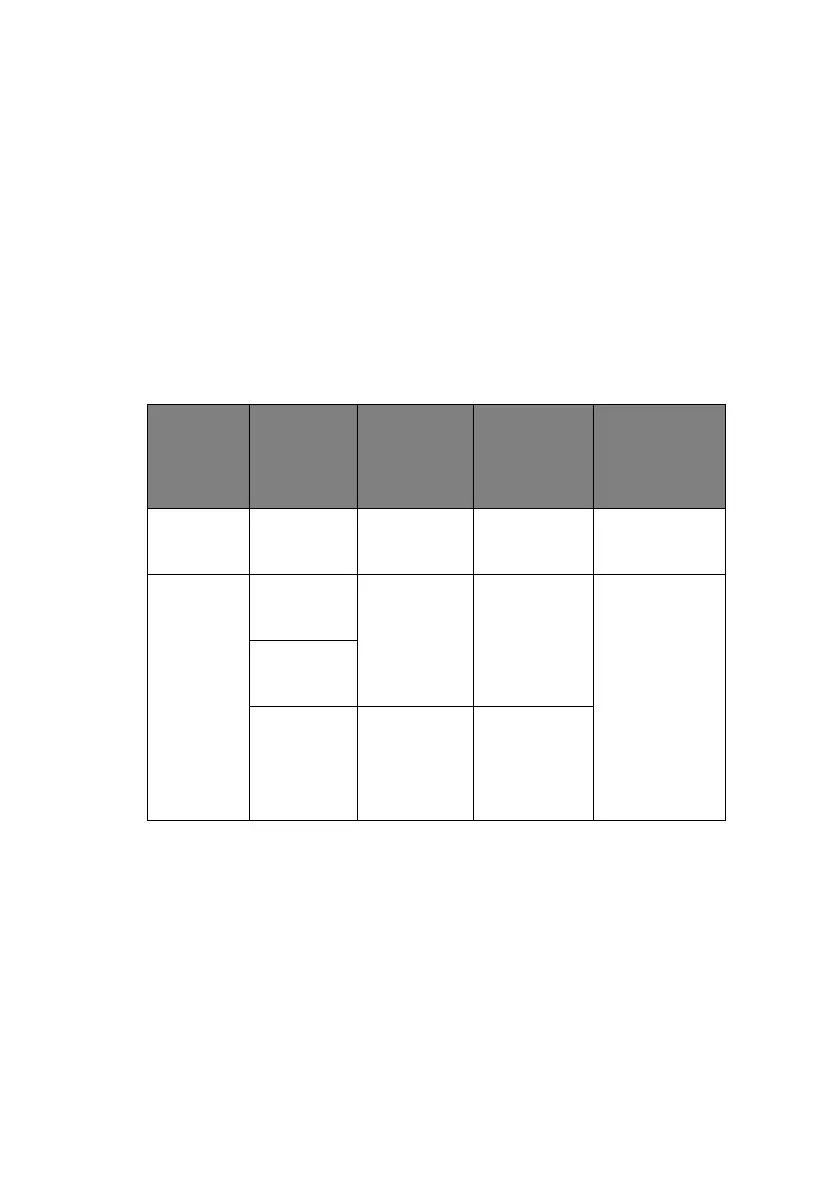

The following table shows usable paper weights and the

maximum number of printing form parts:

NOTE

1. Paper weight is that of 1,000 sheets, each having a unit

area (788 x 1,091 mm), and is expressed in kg.

2. The thickness of carbon paper used as interleaved paper

must be 0.03 mm or less.

M

ETHODS

FOR

JOINING

PARTS

OF

MULTIPART

FORMS

Spot gluing or stapleless stapling is used for joining the parts of

each multipart form. To prevent misalignment between parts,

gluing is required. Stapleless stapling may cause a misalignment

TYPE PAPER

QUALITY

WEIGHT

(NOTE 1)

MAXIMUM

NUMBER

OF FORM

PARTS

TOTAL

PAPER

THICKNESS

Single-part

form

High quality

paper

45 to 70 kg

(52 to 82

gsm)

––

Multipart

form for

rear

tractor

Pressure-

sensitive

paper

34 to 50 kg

(40 to 58

gsm)

Five parts

(original +

five parts)

0.39 mm or

less

Carbon-

backed

paper

Interleaved

paper

(Note 2)

Paper 29 to

34 kg (34 to

40 gsm)

Carbon

paper 39 kg

(34gsm)

Four parts

(original +

three parts)

Loading...

Loading...