Troubleshooting the Anesthetic Gas Module 9 Anesthetic Gas Module

213

Calibration Checks

To access the Gas Analyzer Calibration window select Gas Analyzer Calibration in the

Setup Gas Analyzer menu.

A Passed/Failed indication is displayed for the Zero and the Span calibrations. Refer

to the table below for possible causes of

Failed indications, and their recommended

corrective actions.

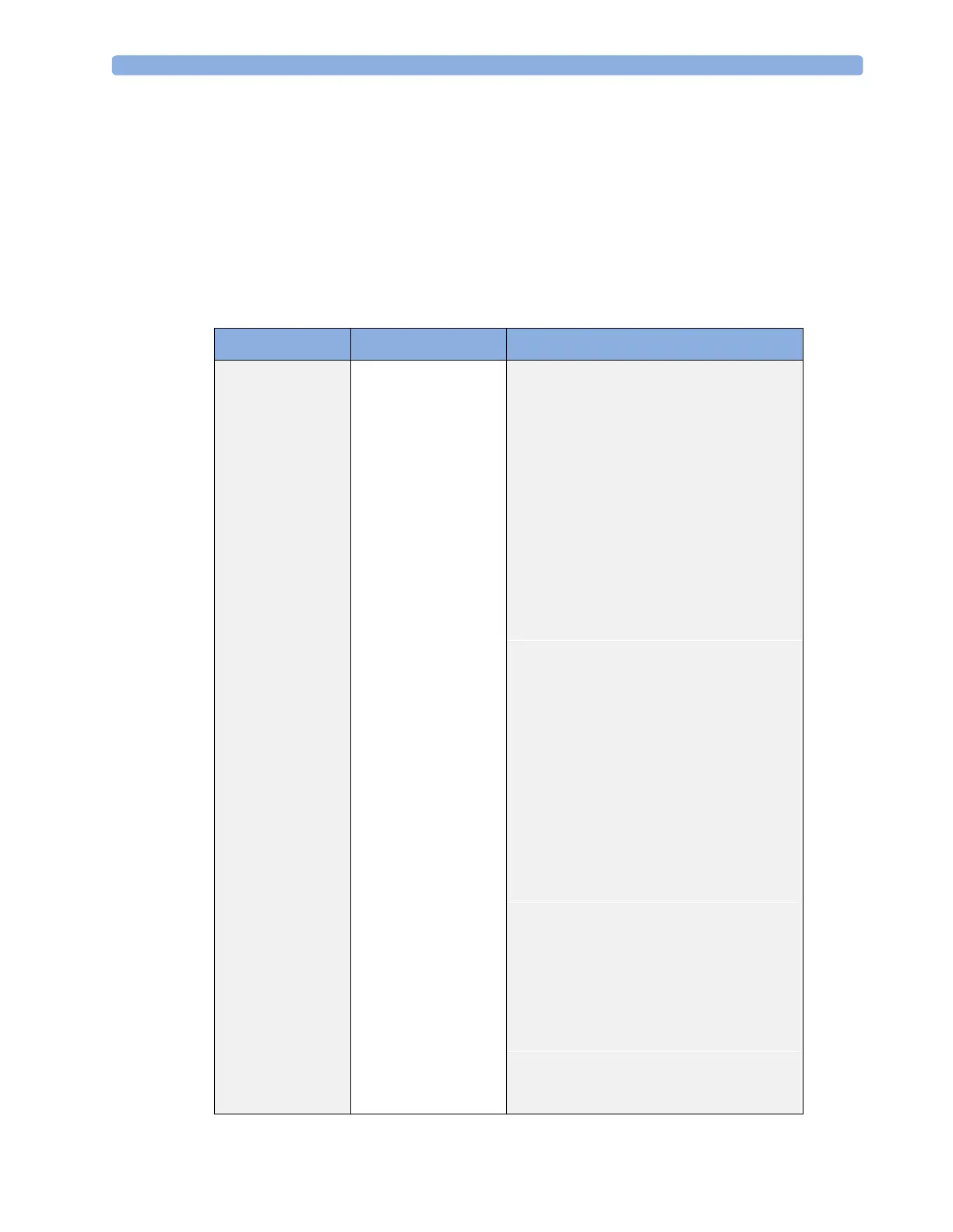

Calibration Checks Troubleshooting Table

Symptom Possible Cause Corrective Action

Zero calibration

shows

Failed/

Agent-ID Zero

Calibration failed.

(Agent-ID Zero

failed is only seen as

INOP in monitoring

mode)

Solenoid or air reference

filter problem.

Check the solenoid while running a Zero

calibration, by feeling whether air is being

pulled in at the room air filter. If not, first

replace the room air filter. If the problem still

persists, replace the solenoid. If Agent-ID zero

calibration failed, check solenoid #2.

Occluded pneumatics

Check for an occlusion, such as bent or

collapsed tubing. Listen for a louder or higher

frequency pump noise. This can indicate that

the pump is working to compensate for an

internal occlusion. Replace watertrap/tubing/

filter, if necessary.

Flowrate problem.

Perform leakage check. If problem still persists,

perform flowrate check.

Flow transducer

incorrectly connected to

flow restrictor

Check that the transducer ports A and B on the

Main PC board are connected to the correct

side of the flow restrictor.

Pump problem

Block the gas inlet port and verify that the

pump is driven harder to compensate for the

reduction in flow. Perform pump test provided

in the Preventative Maintenance kit. Caution:

The instructions on cleaning apply only to the

“old-type” square shaped pump; do not clean

the “new type” round pump. If the pump fails

the test, replace it.

IR measurement head

problem

Check out IR measurement head . Replace if

necessary.

Agent-ID problem

Check out Agent-ID. Replace if necessary.

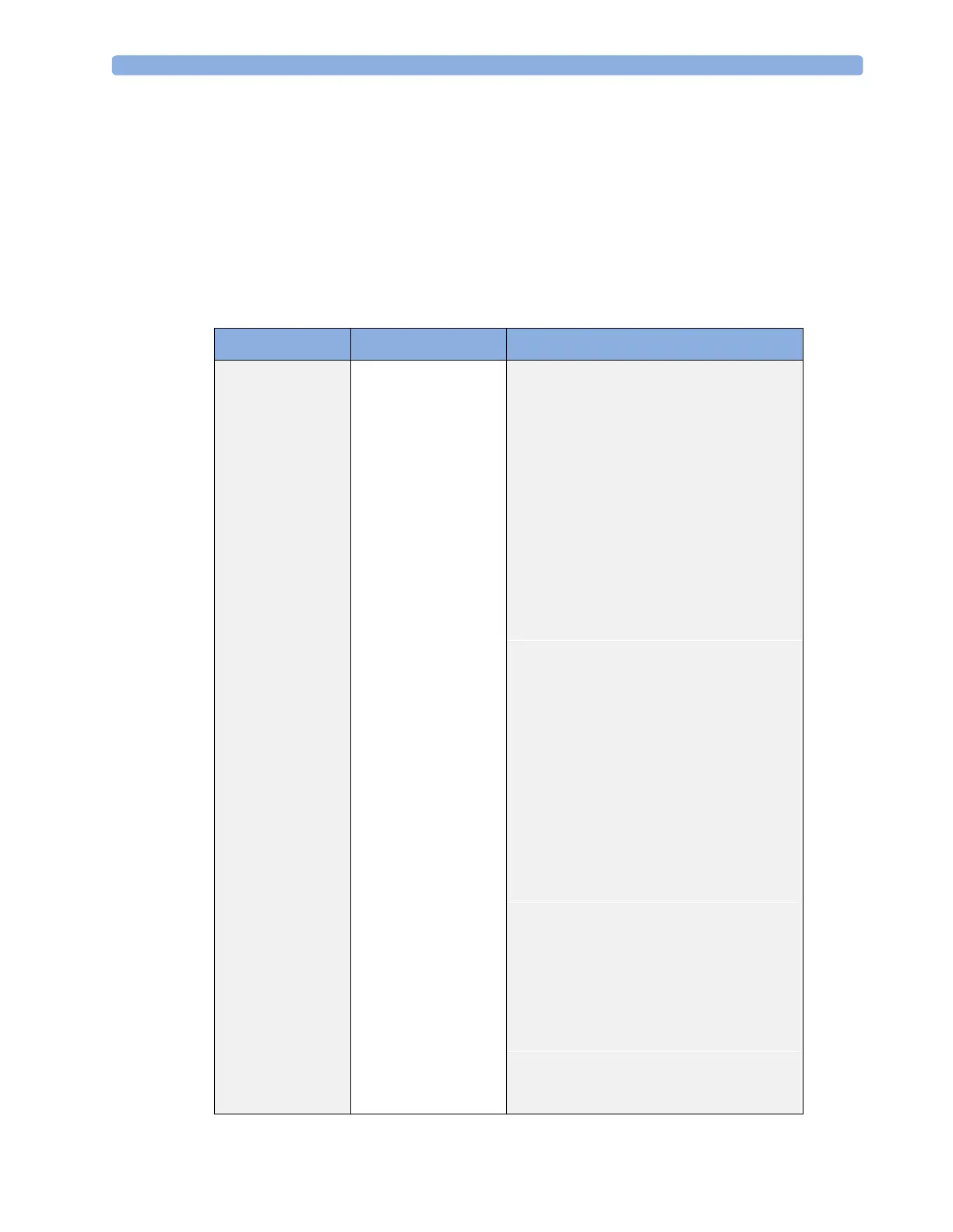

O

2

Zero calibration

shows

Failed.

Flowrate problem.

Perform leakage check. If problem still persists,

perform flowrate check.

O

2

Span problem Perform a Zero calibration followed by a Span

calibration. Check that the Span calibration is

within the accepted tolerance. If not, repeat the

Zero and Span calibration one more time.

O

2

sensor problem. If calibration still fails, perform the O

2

check for

a defective sensor as described above. If the O

2

check fails, replace the O

2

sensor.

Loading...

Loading...