9 Anesthetic Gas Module Repairing the Anesthetic Gas Module

262

Test and Inspection Matrix

The Test and Inspection Matrix describes:

• which tests need to be performed

• the expected test results

• what should be written by Philips service personnel on the Philips Installation Report or Customer

Service Order (CSO).

The second section When to Perform Test Blocks describes when the tests should be performed.

These tables should be followed for all installations and repairs.

NOTE The test procedures outlined for this test block are to be used only for verifying safe installation or

service of the product in question. The setups for these tests and the acceptable ranges or values are

derived from local and international standards but may not be equivalent. These are not a substitute for

local safety testing where it is required for an installation or service event.

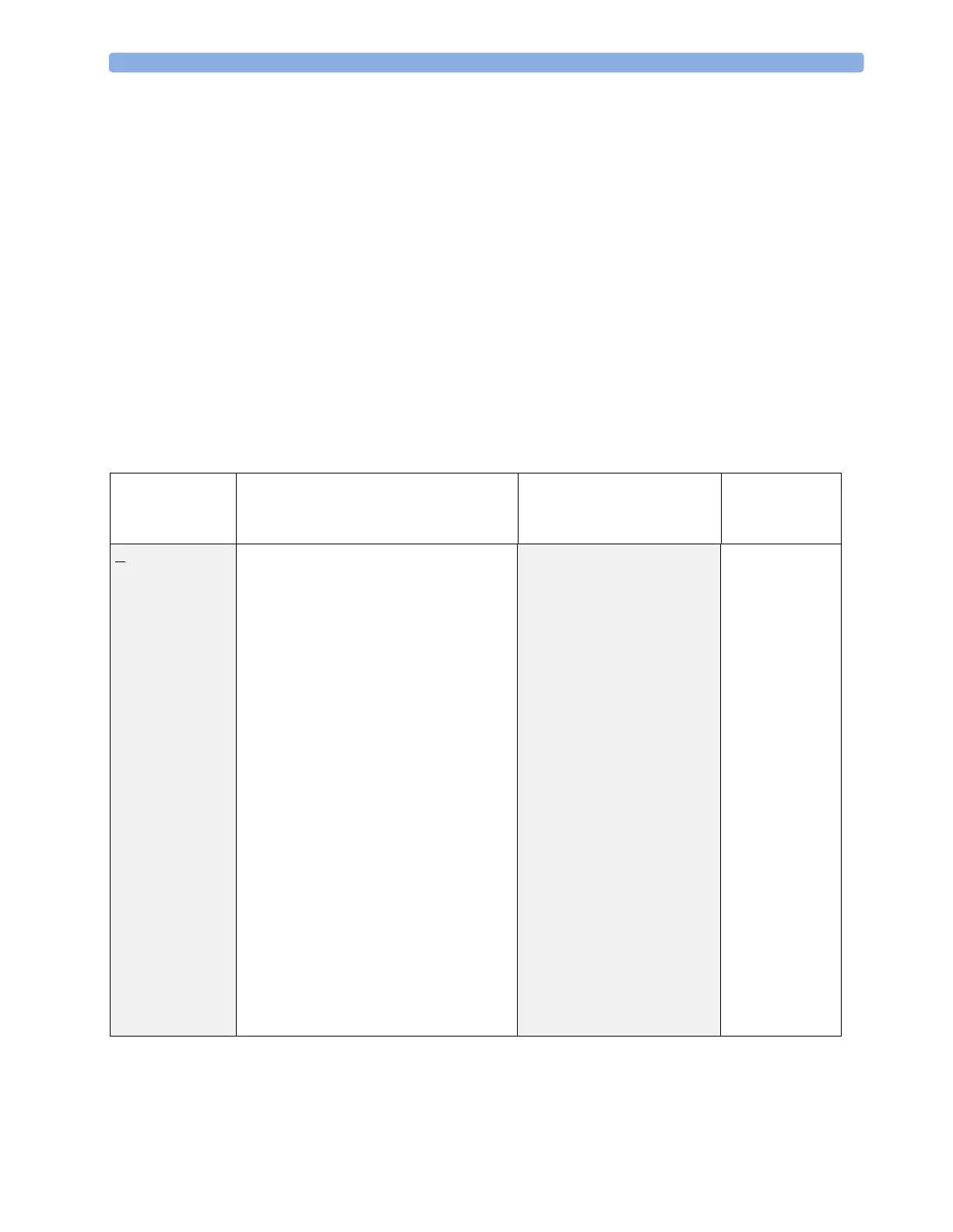

Test Bloc k Na m e Test or Inspection to be performed Expected Test Result What to Record

on Service

Record

Visual Check for any mechanical damage and all

external leads and accessories. Is the device

free of damage and are all accessories properly

set up?

Expected answer is "yes".

If so, visual test is passed.

V: P or

V: F

where P=Pass and

F=Fail

Power On Switch on the module. A built-in selftest and

communication test are running for two

minutes after "Power On". The green setup

LED near the power button indicates by

flashing if one of the tests failed. When tests

are successfully completed after 2 minutes the

LED is off and the AGM will enter warmup

mode (indicated by INOP

"GA.WARMUP").

Does AGM boot up successfully without

displaying any error or malfunction messages?

Expected answer is "yes". If so,

PowerOn test is passed.

PO: P or

PO: F

where P=Pass and

F=Fail

Performance

Leakage Check

Perform Leakage Check Measured flow value:

0-4 ml/min

PL: P or

PL: F

where P=Pass and

F=Fail

Loading...

Loading...