Rockwell Automation Publication 193-UM015D-EN-P - February 2015 49

Installation and Wiring Chapter 2

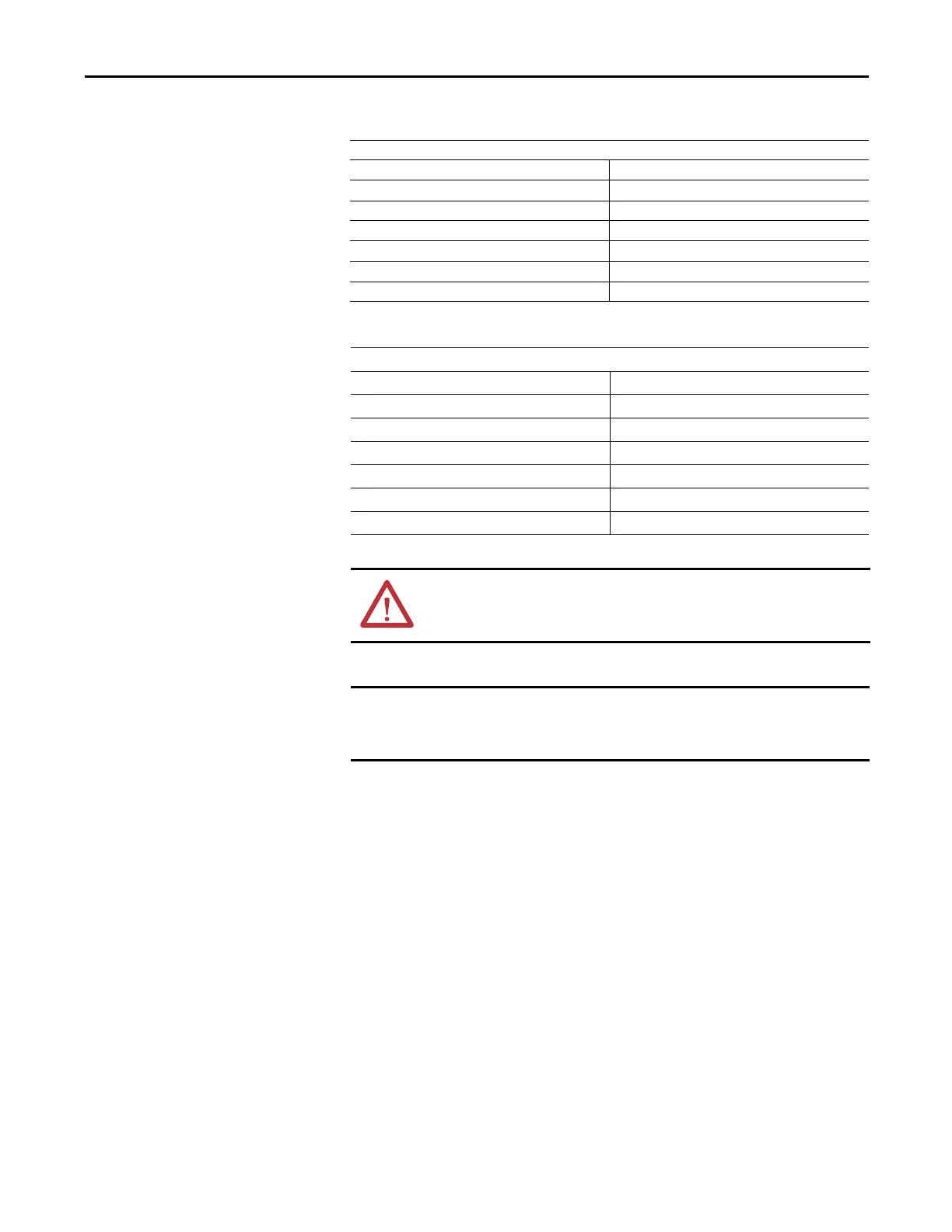

Table 13 - CT Primary (Parameter 263)

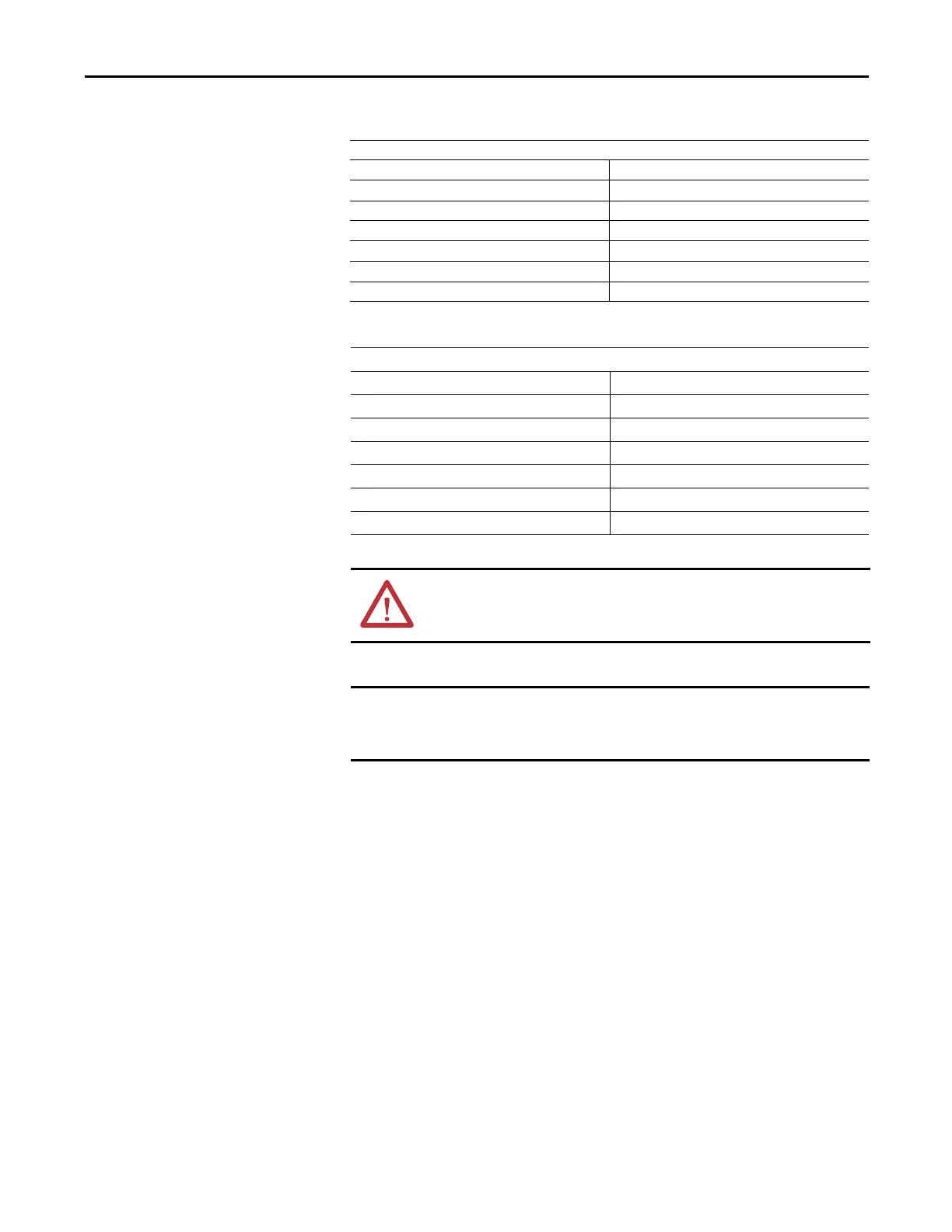

Table 14 - CT Secondary (Parameter 264)

You shall (1) provide one CT for each motor phase and shall (2) connect the

CT’s secondary leads to the appropriate sensing module power terminals. The

CTs shall be selected to be capable of providing the required VA to the secondary

load, which includes the E300 Sensing Module burden of 0.1 VA at the rated

secondary current and the wiring burden. Finally, the CT shall (1) be rated for

Protective Relaying to accommodate the high inrush currents associated with

motor startup and shall (2) be accurate to within ≤±2% over its normal operating

range. Typical CT ratings include:

• ANSI USA

• CSA (Canada)

• IEC (Europe)

• Class C5 BO.1

• Class 10L5

• 5 VA Class SP10

CT Primary (Parameter 263)

Default Value 5

Minimum Value 1

Maximum Value 65535

Parameter Type UINT

Size (Bytes) 2

Scaling Factor 1

Units Amps

CT Secondary (Parameter 264)

Default Value 5

Minimum Value 1

Maximum Value 65535

Parameter Type UINT

Size (Bytes) 2

Scaling Factor 1

Units Amps

ATTENTION: Improper configuration of the CT Ratio parameters can make the

E300 Electronic Overload Relay report inaccurate motor operational data and

possible motor damage.

The E300 Electronic Overload Relay trip on a configuration fault when the FLA

setting is outside of the legal range of the selected CT Ratio settings. The TRIP/

WARN LED status indicator flashes red 3-long, 8-short blinking pattern.

Loading...

Loading...