Page 175

STAT

IM

2000/2000S Service Guide

96-108639 Rev 3.0

8. Water Pumps, Reservoir, and Compressor

STATIM 2000/2000S/2000 G4 Service Guide

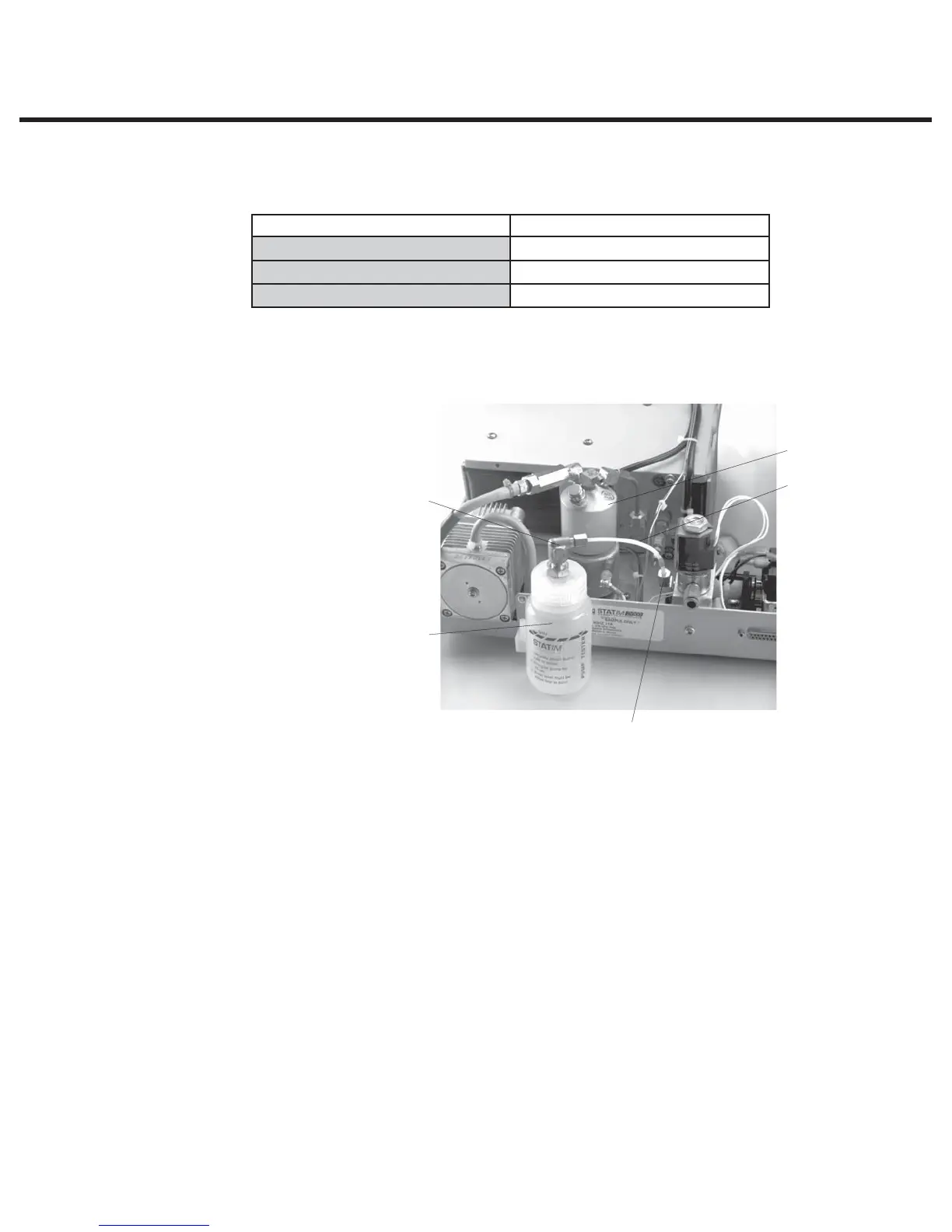

As a guide to the tube size required if changing the tube is considered, the nominal tube sizes for

STAT

IM

2000 models as fitted during production should be as follows:

Unit / Voltage Rating Nominal Tubing

*STATIM 100 V

0.0270

*STATIM 115 V

0.0255

*STATIM 230 V

0.0245

Note: These are for aluminium boilers only. If a unit is fitted with a stainless steel steam

generator, the value will likely be in the region of a difference of 0.0040” larger. For example, a

0.0245” tube fitted to an aluminium steam generator may be 0.0285” on a stainless steel steam

generator.

If, as a result of a failed pump flow check after a filter maintenance, the tube may be changed

as follows (see Figure 12):

1. Turn the unit OFF.

2. Using a 3/8-inch wrench disconnect the pump tube (1) from the top of the steam generator

(2) or pump test bottle (6) as appropriate, and disconnect the other end from the pump outlet

fitting (3). Record the orifice diameter and discard the tube.

3. Select a smaller or larger size tube (depending on whether pump is over or under delivering).

Note: There is no prescribed formula over which diameter to select. Selection will need to

be based on perception of the under or over delivery amount.

4. Connect the pump end of the new tube to the pump outlet fitting. A label on the tube indicates

the tube orifice diameter. An arrow on the label indicates the direction in which the tube must

be installed. The arrow must point towards the steam generator when installed.

5. Thread the other end of the replacement tube (4) to the fitting (5) on the pump test bottle (6)

until finger tight. Do not cross thread the fittings. Do not overtighten.

1. Steam generator inlet tube

2. Steam generator

3. Pump outlet fitting

4. Replacement tube

5. Fitting (pump test bottle)

6. Pump test bottle

Figure 12

1, 4

2

3

5

6

Loading...

Loading...