Page 71

STAT

IM

2000/2000S Service Guide

96-108639 Rev 3.0

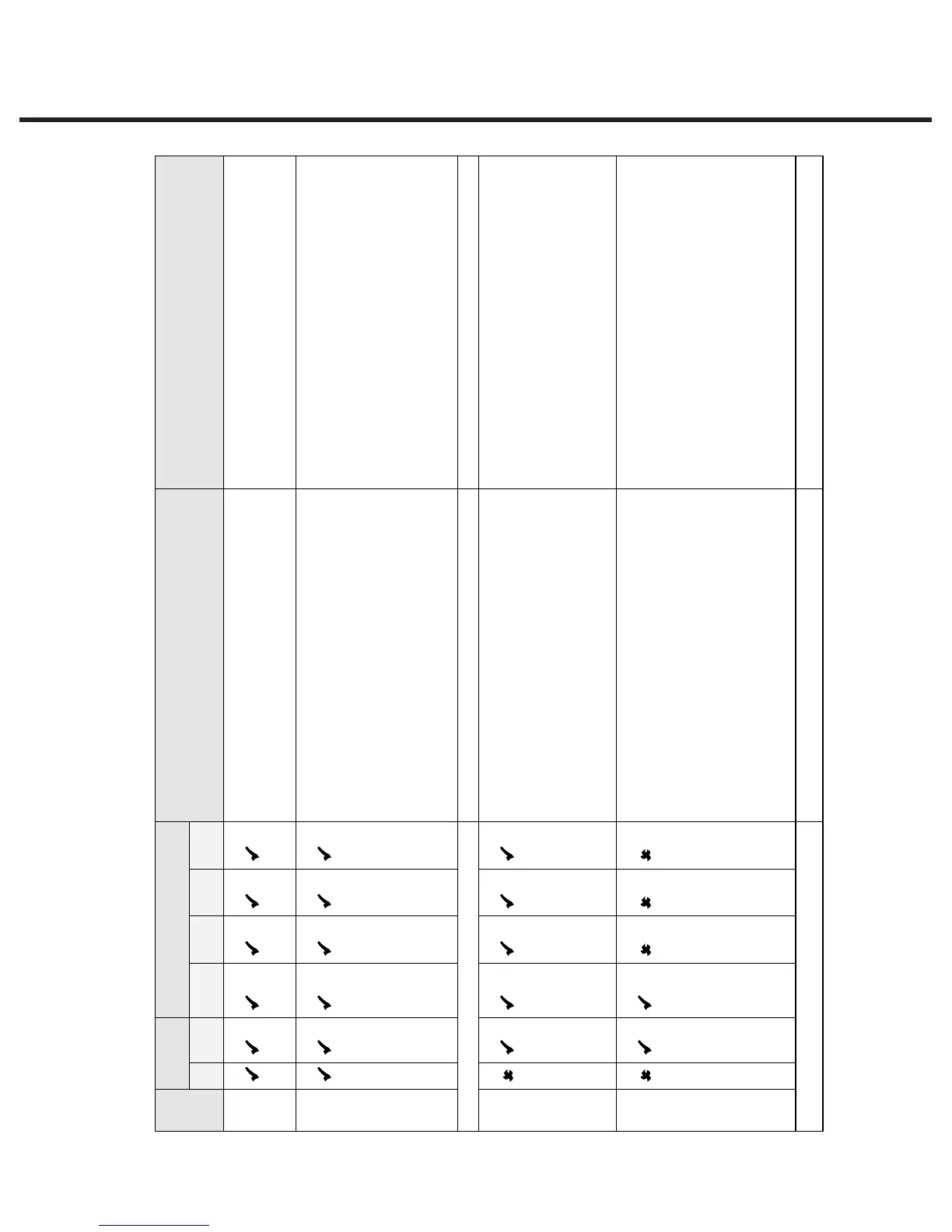

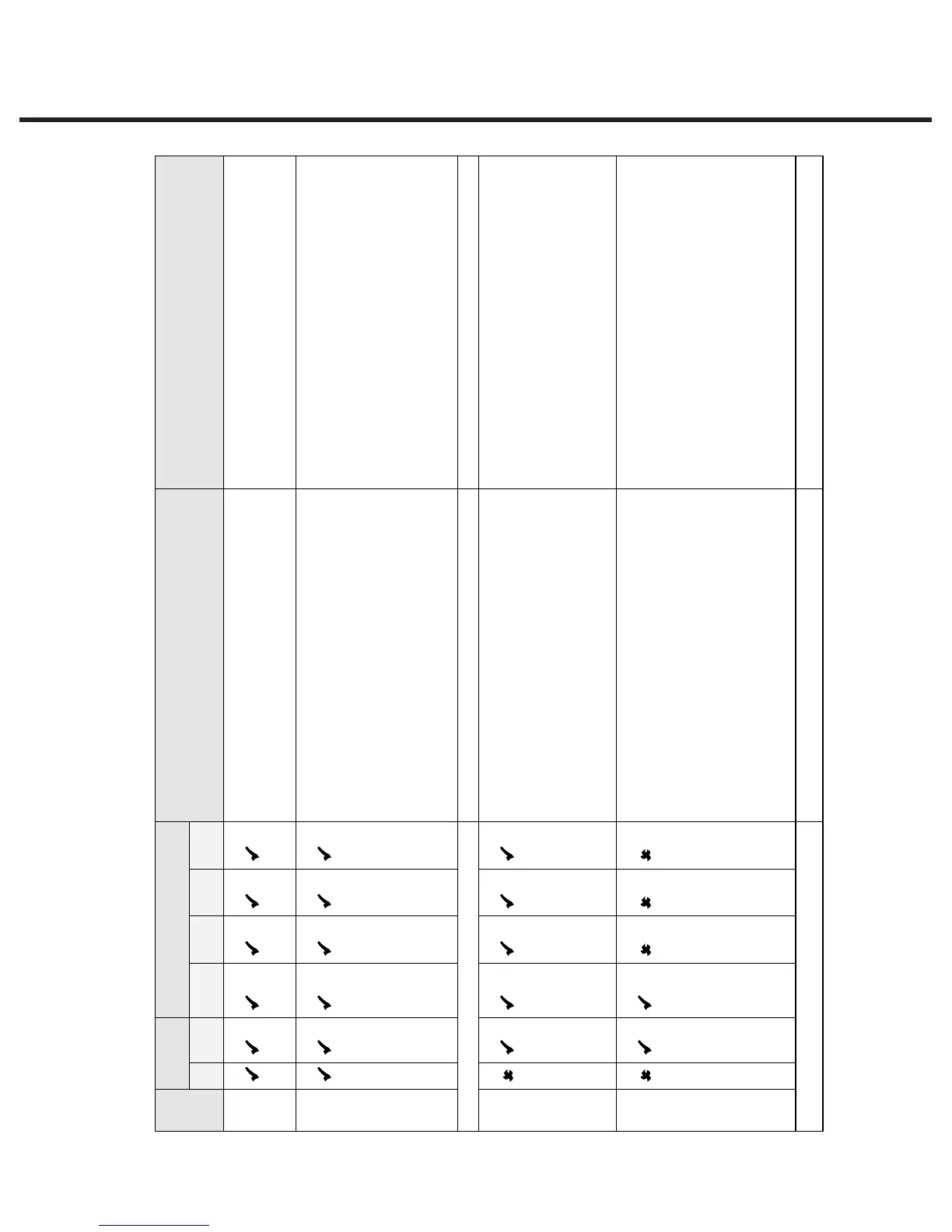

3. Troubleshooting Cycle Faults

STATIM 2000/2000S/2000 G4 Service Guide

CF

No.

Unit

type

Software revision

Description of Fault

Probable Cause (or causes) of Fault

S Non

S

1.xx/

2.xx

4.xx 5.xx 6.xx/

7.xx

15

The cassette temperature rose above the high

threshold during the sterilization phase of a

cycle or above 138.6°C during conditioning or

pressurizing phase of the cycle

% Blocked cassette exhaust duct

% Obstructed exhaust tubing (kink)

% Sticking solenoid valve (closed)

% Failed solenoid coil

16

The steam generator temperature went above a

threshold value. (overheat)

% Blocked pump filters

% Weak pump

% Blocked or kinked pump tube

% Failed pump

% Failed pump triac

% Failed steam generator triac

% Sticking solenoid valve (closed)

% Failed solenoid coil

% Faulty seal installation

17 - 18

Not used

19

For software rev. R1xx, R2xx and R4xx the

steam generator calibration is invalid.

For software rev. R5xx and R6xx the validation

thermocouple calibration is invalid.

% This occurs when a new controller board

or microprocessor has been installed.

This may also happen when the unit has

been subjected to a strong static

discharge corrupting the memory.

% In both cases a new steam generator or

validation thermocouple calibration is

required.

20

The pump has failed to pump water into the

steam generator during a pre-vent pump time-

out. The steam generator temperature was

greater than 140°C for 3.6 seconds after the

pump was activated to pump water to cool the

steam generator.

% Blocked pump filters

% Weak pump

% Blocked or kinked pump tube

% Failed pump

% Failed pump triac

% Failed steam generator triac

% Sticking solenoid valve (closed)

% Failed solenoid coil

% Faulty seal installation

% Failed water sensor (level)

21 - 24

Not used

Loading...

Loading...