Page 70

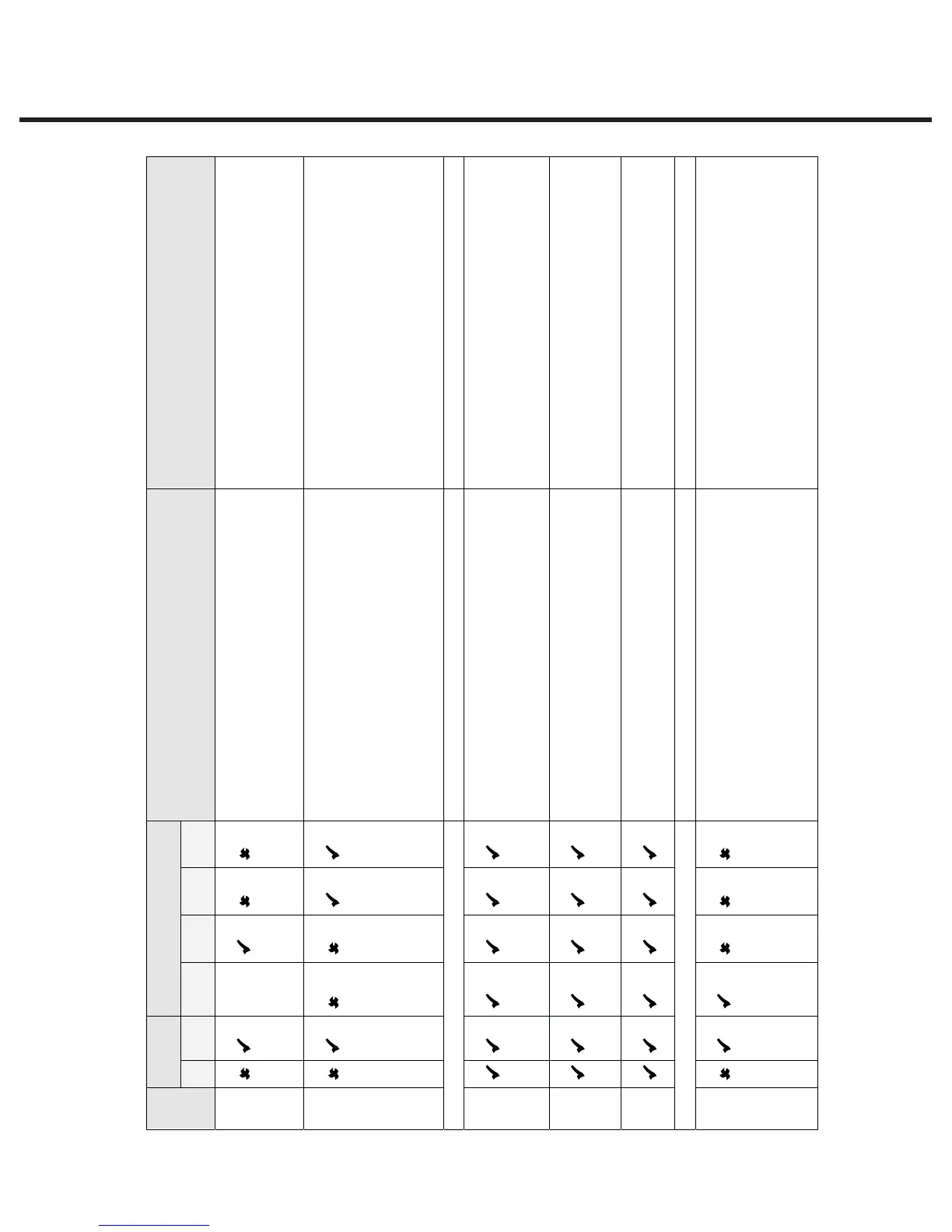

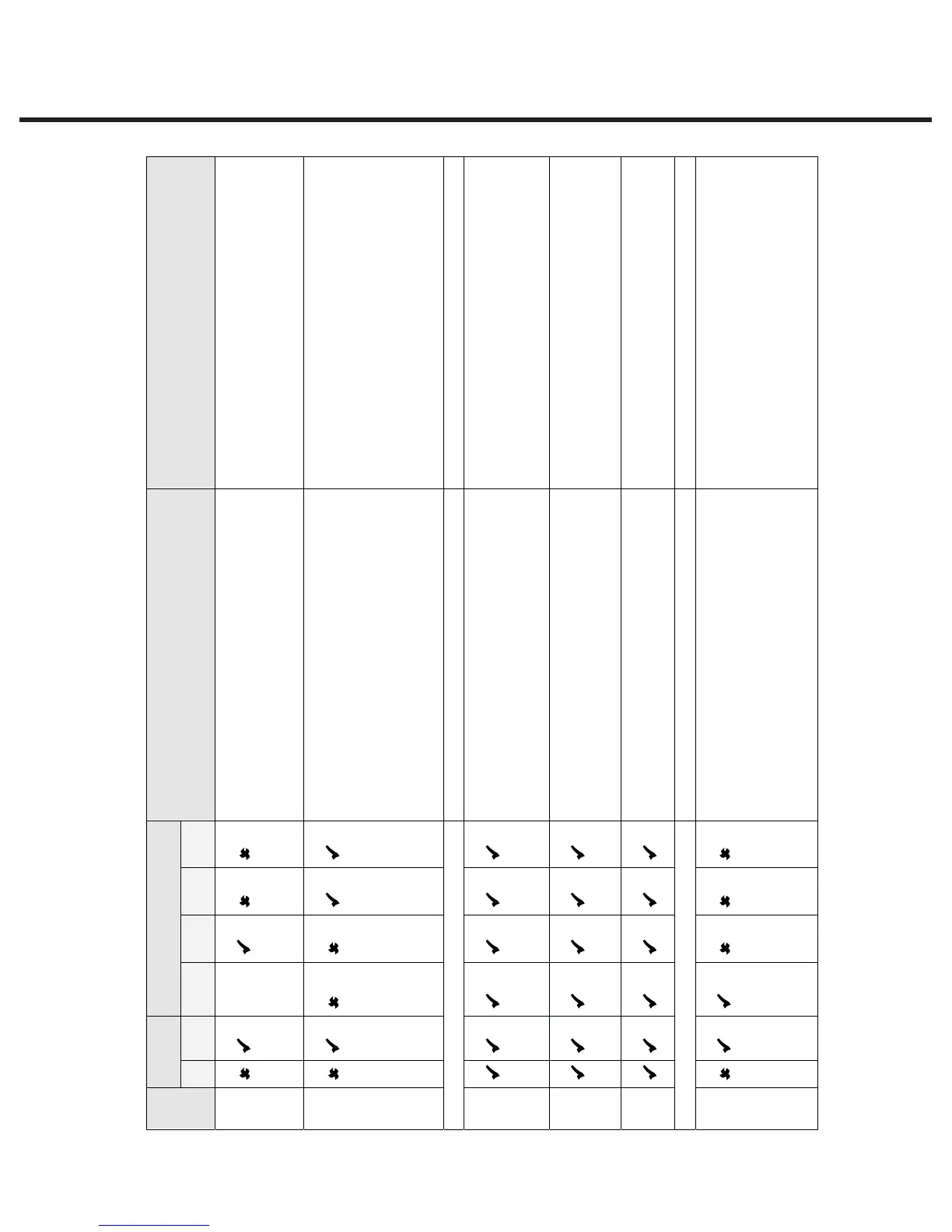

STAT

IM

2000/2000S Service Guide

96-108639 Rev 3.0

3. Troubleshooting Cycle Faults

STATIM 2000/2000S/2000 G4 Service Guide

CF

No.

Unit

type

Software revision

Description of Fault

Probable Cause (or causes) of Fault

S Non

S

1.xx/

2.xx

4.xx 5.xx 6.xx/

7.xx

8

(i)

2.xx

only

The software has detected the filtered steam

generator temperature 6°C less than the

chamber during the sterilizing phase of a cycle.

% Contaminated steam generator

% Failed steam generator

% Calibration imbalance (boiler to

chamber)

% High pump flow

8

(ii)

The software has detected the Validation

Thermocouple temperature to be 5°C less than

the chamber temperature during the sterilizing

phase of a cycle.

% Calibration imbalance (validation

thermocouple to chamber

thermocouple)

% High pump flow

% Blocked cassette exhaust duct

% Sticking solenoid valve

Check Vref is 2.520V± 0.001V (all software

revisions OTHER THAN revision 6.xx)

9

Not used

10

During conditioning (purging), the cassette

temperature has failed to drop to115°C during

the Unwrapped or Wrapped Cycle OR the

temperature has failed to drop to 110°C during

the Rubber and Plastics Cycle.

% Blocked cassette exhaust duct

% Obstructed exhaust tubing (kink)

% Sticking solenoid valve (closed)

% Failed solenoid coil

11

The cassette temperature has failed to drop to

102°C within a timeout period of the end of a

cycle during venting.

% Blocked cassette exhaust duct

% Obstructed exhaust tubing (kink)

% Sticking solenoid valve (closed)

%

Failed solenoid coil

12

This indicates a problem with the temperature

measuring system.

% Broken or faulty thermocouple

% Circuit failure on PCB

13

Not used

14

The steam generator temperature is above

171°C during the sterilization phase of a cycle.

% Poor pump delivery

% Calibration imbalance (boiler

thermocouple to chamber

thermocouple)

% Failed water sensor (level)

Loading...

Loading...