Page 69

STAT

IM

2000/2000S Service Guide

96-108639 Rev 3.0

3. Troubleshooting Cycle Faults

STATIM 2000/2000S/2000 G4 Service Guide

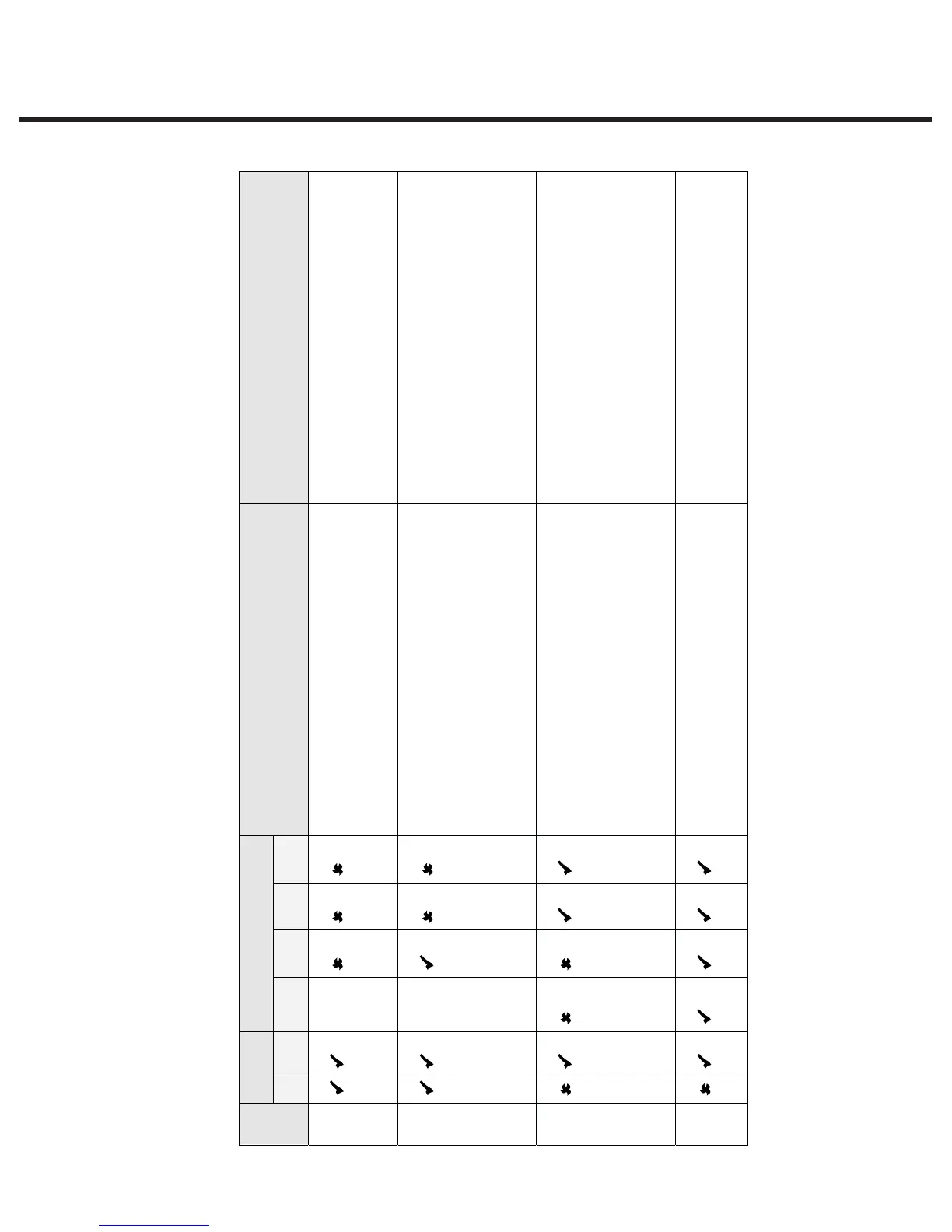

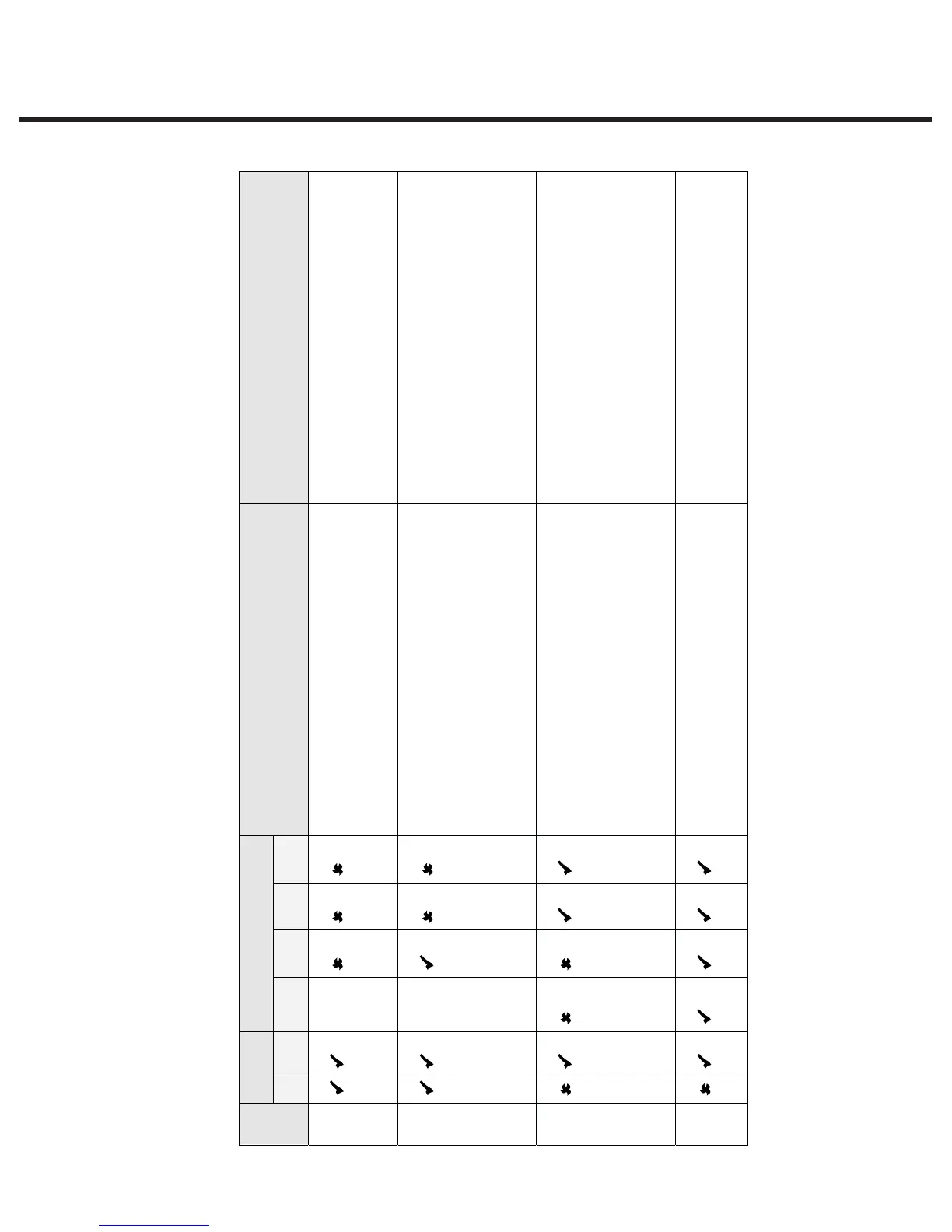

CF

No.

Unit

type

Software revision

Description of Fault

Probable Cause (or causes) of Fault

S Non

S

1.xx/

2.xx

4.xx 5.xx 6.xx/

7.xx

5

1.xx

only

The software causes the pump to activate at

predetermined times. If a request to pump water

occurs outside of the predetermined time Cycle

Fault #5 occurs.

% Leaky cassette

% Kinked pump tube

% Leaking solenoid valve

% Poor pump delivery

%

Overloaded cassette

6

(i)

2.xx

only

The software has detected the filtered steam

generator temperature 6°C greater than the

chamber during the sterilizing phase of a cycle.

% Obstruction caused by:

o Seal misalignment

o Foreign material in the seal

channel

% Calibration imbalance (boiler

thermocouple to chamber

thermocouple)

% Contaminated steam generator

6

(ii)

The software has detected the Validation

thermocouple temperature to be 5°C greater

than the chamber during the sterilizing phase of

a cycle.

% Cassette steam leak

% Sticking solenoid

% Obstructed exhaust tubing (kink)

% Calibration imbalance (validation

thermocouple to chamber

thermocouple)

Check Vref is 2.520V± 0.001V (all software

revisions OTHER THAN revision 6.xx)

7

During the sterilization phase of the cycle the

cassette temperature has dropped below a

threshold value.

% Sticking solenoid valve (open)

% Cassette leak

% Check valve leak

% PRV leak

Loading...

Loading...