Cabinet design and EMC

12.7 Protective connection and equipotential bonding

SINAMICS S120 Combi

Manual, 11/2017, 6SL3097-4AV00-0BP7

293

Protective connection and equipotential bonding

Protective connections

The S120 Combi is designed for use in control cabinets with a protective conductor

connection.

The protective conductor connection of the S120 Combi must be connected to the protective

conductor connection of the control cabinet as follows:

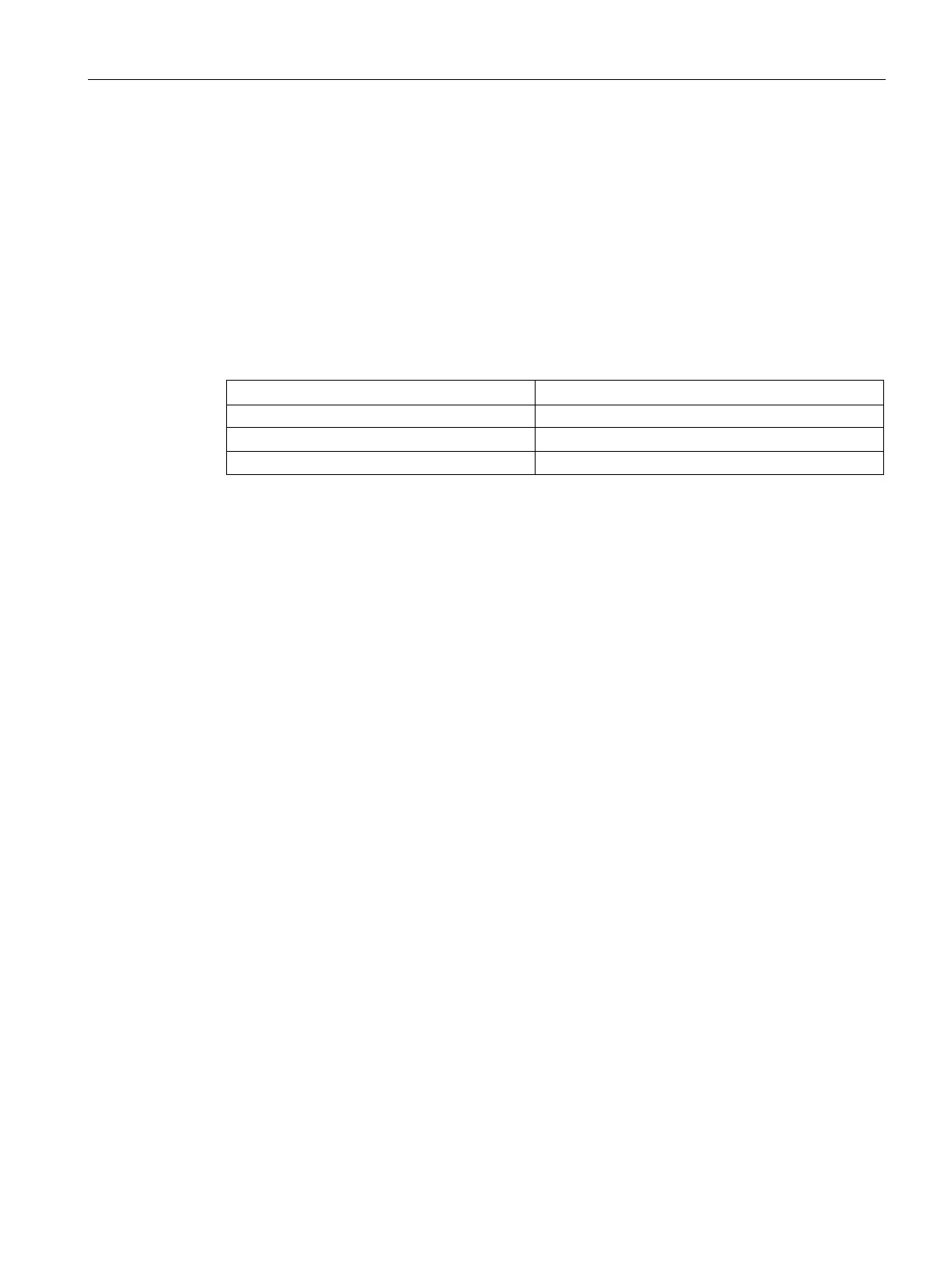

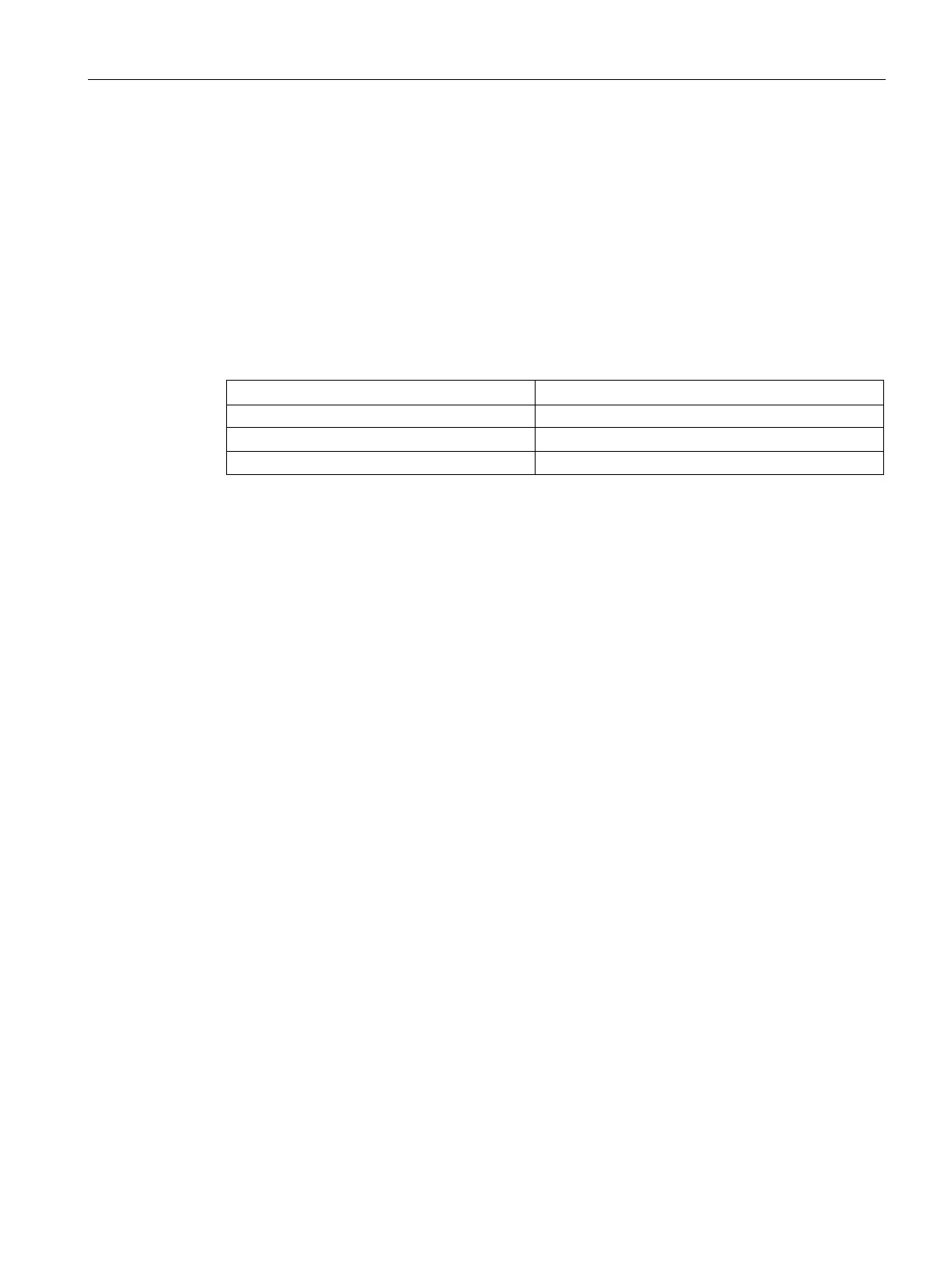

Table 12- 14 Cross-section for copper protective conductors

Protective connection in mm

2

copper

2

The same as the line supply cable

From 16 mm

2

to 35 mm

2

16 mm

2

2

For materials other than copper, the cross-section should be increased so that as a

minimum, the same conductivity is attained.

All plant and machine parts must be incorporated in the protective concept.

The protective ground connection of the motors used must be established through the motor

cable. For EMC reasons, these protective ground connections should be connected at the

S120 Combi.

Installation regulations in the area of validity of IEC/EN

IEC 61800-5-1, Section 4.3.5.4, Table 5 (see also IEC 60364-5-54 Table 54.2) is the basic

regulation, according to which the protective conductor must have the same minimum cross-

section up to a line conductor cross-section of 16 mm.

Alternatively, the protective conductor can be dimensioned according to IEC 60364-5-54,

Section 543.1.2. Taking the I

2

t values of the specified protective equipment into account, the

minimum conductor cross-section must be 6 mm

2

(copper).

Installation regulation in the area of validity of UL/CSA (NEC for USA / CEC for Canada)

The respective National Electrical Code applies in the USA and Canada. The minimum

cross-section of the protective conductor should be dimensioned according to the rated

current of the corresponding protective device. Taking the specified protective device up to

60 A into account, the minimum conductor cross-section for the protective conductor must be

AWG 10 or 6 mm

2

(copper).

A mounting plate serves simultaneously as an equipotential bonding surface. This means

that no additional equipotential bonding is required within the drive line-up. The mounting

plate must be connected to the protective conductor connection of the control cabinet

through a low impedance.

If a common metallic bright mounting plate is not available, equally good equipotential

bonding must be ensured using the cable cross-sections listed in the table above or with at

least the same conductivity.

Loading...

Loading...