S120 Combi Power Modules

4.3 Interface description

SINAMICS S120 Combi

Manual, 11/2017, 6SL3097-4AV00-0BP7

79

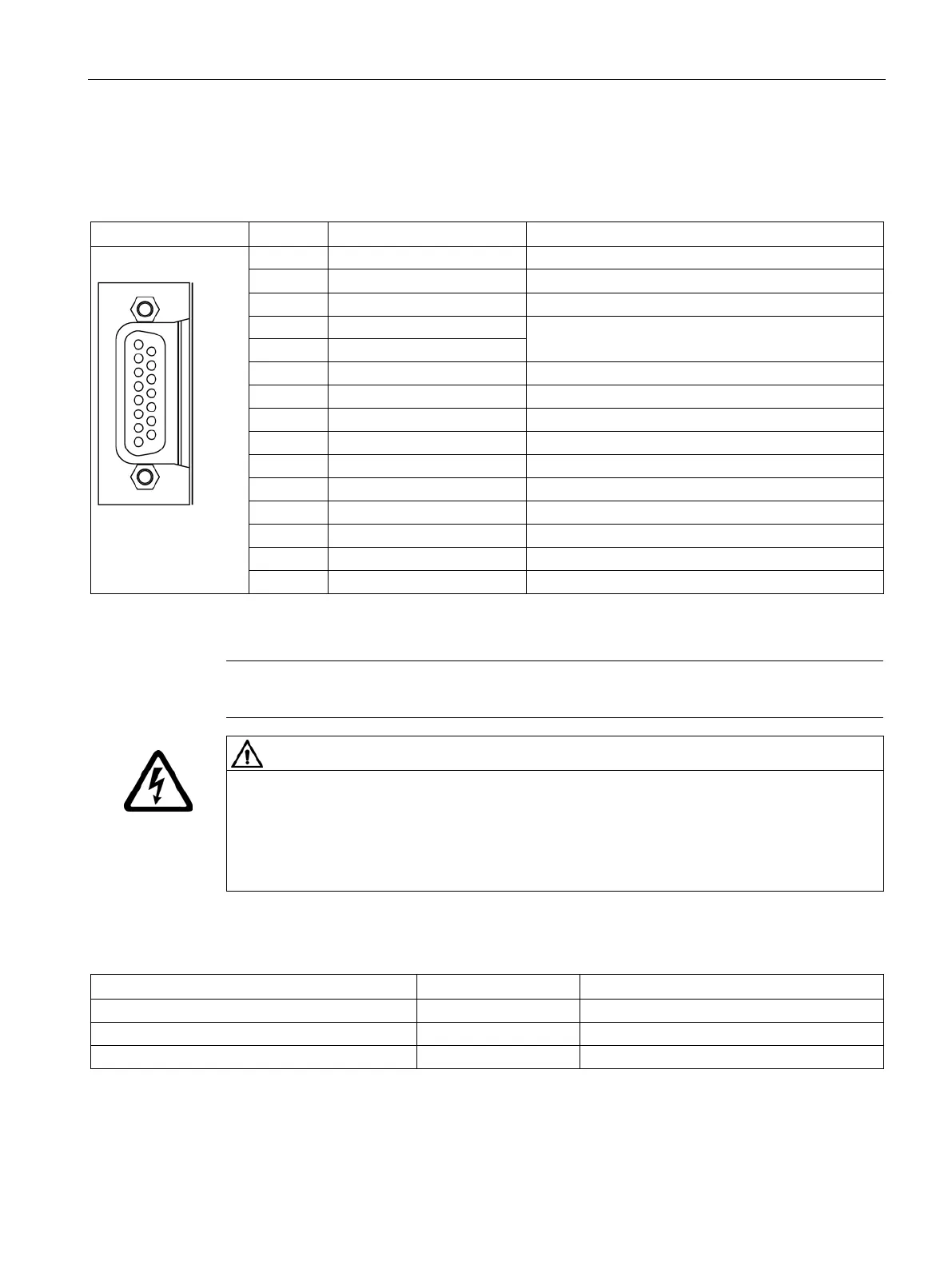

Table 4- 13 Encoder interface X220

Temperature sensor KTY84-1C130 / PT1000 / PTC

2 Clock Clock

Encoder power supply

Sense input of encoder power supply

Ground for encoder power supply

Temperature sensor KTY84-1C130 / PT1000 / PTC

Inverse reference signal R

Inverse incremental signal B

Inverse incremental signal A

Type: Sub-D socket, 15-pin; TTL encoder; max. cable length 100 m

V TTL encoders are supported.

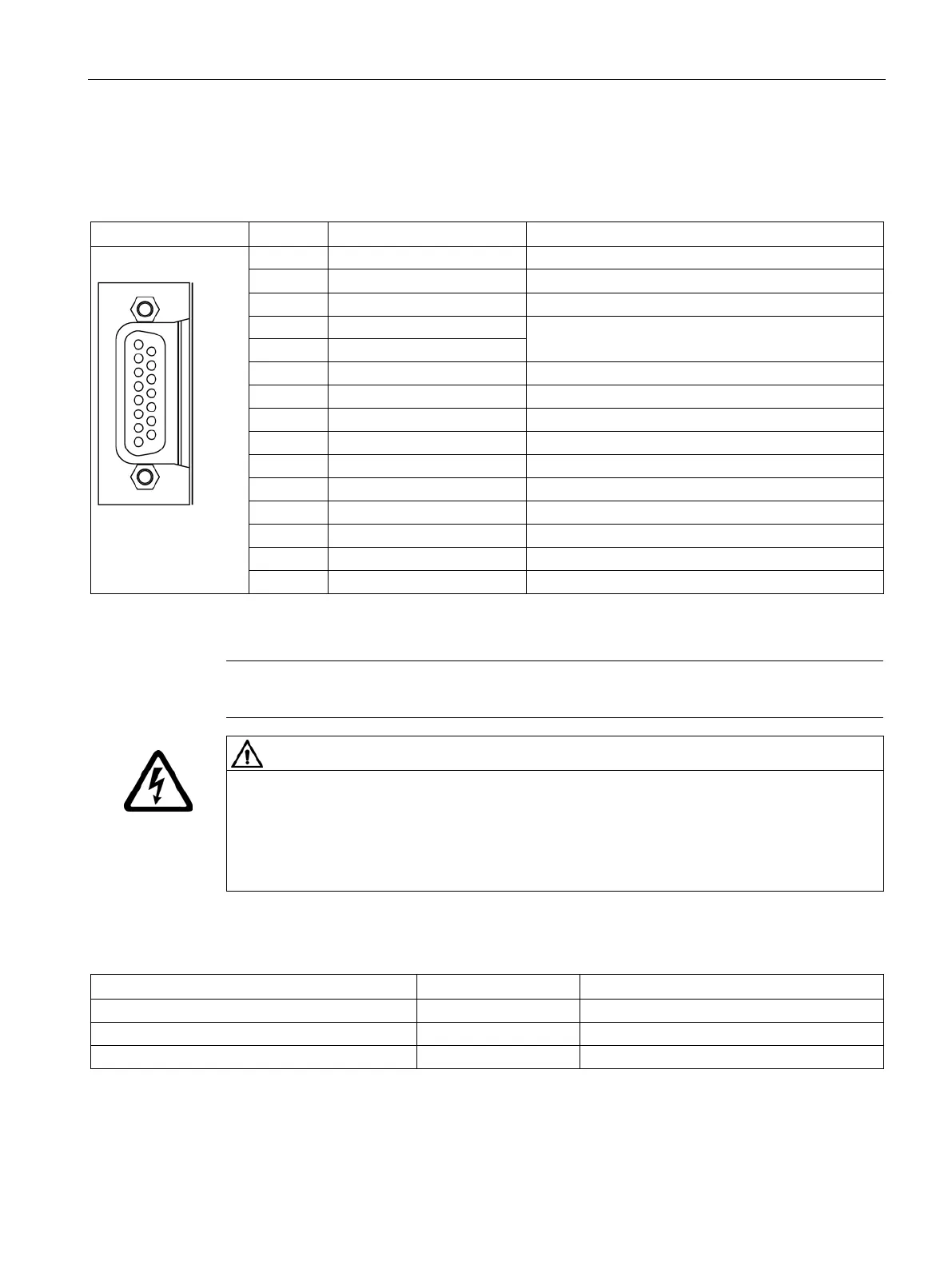

Electric shock in the event of voltage flashovers at the temperature sensor

Voltage flashovers to the signal electronics can occur in motors without safe electrical

separation of the temperature sensors.

• Use temperature sensors that comply with the specifications relating to safe electrical

separation.

Table 4- 14 Technical data of the encoder system supply

DC

5 (with or without remote sense)

1)

Encoder frequency that can be evaluated (f

encoder

A controller compares the encoder system supply voltage - sensed via the remote sense cables - with the reference

supply voltage of the encoder system, and adjusts the supply voltage for the encoder system at the output of the drive

module until the required supply voltage is obtained directly at the encoder system.

Loading...

Loading...